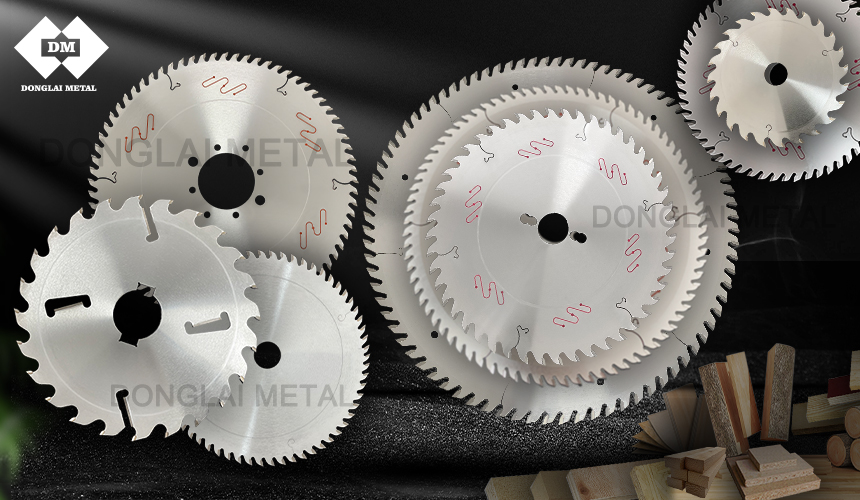

انتخاب تیغه اره چوب مناسب باید مواد چوب را در نظر بگیرد ، موارد زیر برخی از پیشنهادات است:

1.Softwood: مانند کاج ، صنوبر و غیره.

برای چوب نرم ، می توانید یک تیغه اره را با دندانهای نسبتاً کمی انتخاب کنید. از آنجا که چوب نرم از نظر بافت نرم است و به نیروی برش زیادی احتیاج ندارد ، دندان های کمتری می توانند سرعت برش را افزایش داده و گرفتگی خاک اره را کاهش دهند.

ضخامت تیغه اره می تواند کمی نازک تر باشد ، به طوری که مقاومت برش کوچک است که می تواند راندمان پردازش را بهبود بخشد و مواد را صرفه جویی کند.

2.Hardwood: مانند بلوط ، گردو و غیره.

چوب سخت به نیروی برش بیشتری نیاز دارد ، بنابراین شما باید یک تیغه اره را با دندان های بیشتری انتخاب کنید که می تواند سطح برش را نرم تر کند و باعث کاهش برس شود.

ضخامت تیغه اره را می توان به طور مناسب افزایش داد تا از پایداری تیغه اره در هنگام برش چوب سخت اطمینان حاصل شود و آن را به راحتی تغییر شکل ندهد.

به دلیل سختی زیاد و مقاومت در برابر سایش ، باید به تیغه های اره ای از کاربید ساخته شود ، که می تواند بهتر با پردازش چوب سخت مقابله کند و عمر سرویس تیغه اره را گسترش دهد.

3. چوب با گره یا دانه نامنظم

در این حالت ، شما باید یک تیغه اره را با دندانهای چپ یا راست یا دندانهای تراشه مسطح انتخاب کنید ، که باعث می شود تراشه های تراشه را تسهیل کرده و به طور موثری باعث کاهش صدای اره ناشی از گره ها و غیره شود.

طراحی دندان تیغه اره باید بتواند با بافت های نامنظم بهتر مقابله کند و از برش صاف اطمینان حاصل کند.

به طور خلاصه ، هنگام انتخاب تیغه اره چوبی مطابق با مواد چوب ، باید عواملی مانند تعداد دندان ها ، ضخامت ، مواد و شکل دندان را در نظر بگیرید تا به بهترین اثر پردازش و زندگی تیغه اره برسید.