Gilashin sayen lu'u-lu'u na ɗaya daga cikin manyan igiyoyin gani da aka fi amfani da su. Babban fasalin wannan tsintsiya shine cewa an sanya wasu abubuwan da ake sakawa a kan igiya ta hanyar matakai daban-daban a mataki na gaba. Ana amfani da wannan tsintsiya ko'ina a masana'antar yankan dutse da kankare. Wannan labarin ya gabatar da daban-daban wasanni na daban-daban lu'u-lu'u saka saw ruwan wukake ta gabatar da takamaiman halaye na lu'u-lu'u saka saw ruwan wukake.

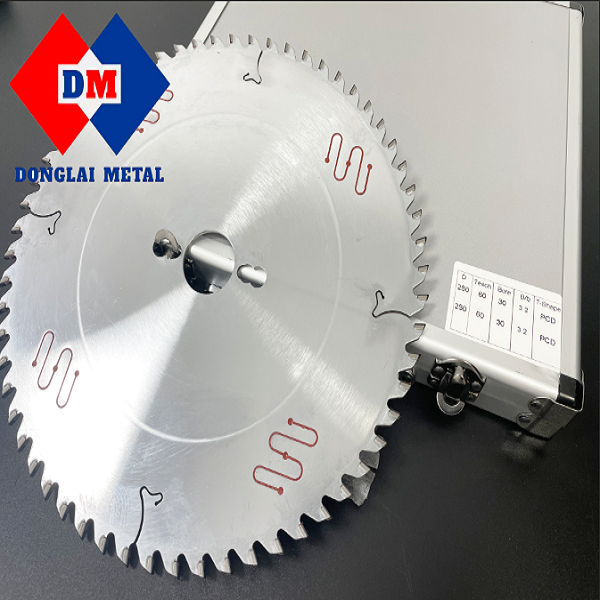

1: PCD lu'u-lu'u saka saw ruwan wukake.

Ana amfani da irin wannan nau'in zato musamman don yankan itace, kuma ana iya amfani da shi wajen sarrafa dutse. Babban fasalin irin wannan nau'in zato shine cewa abin da ake sakawa yayi kama da na TCT, amma bambancin shi ne sashin abin da ake sakawa. Abubuwan da aka sanyawa an yi su ne da gawa mai ƙarfi, kuma tsarin da PCD ɗin ke amfani da shi shi ne cewa wasu fakitin PCD masu haɗawa suna buƙatar waldawa akan ledar. A lokaci guda kuma, ana iya ƙara haɓaka rayuwar sabis na sakawa. Ba kasafai ake sarrafa duwatsu ta PCD ba. Dalili na farko shi ne cewa farashin PCD composite sheets yana da yawa, kuma matsalar bayyanar lu'u-lu'u, don haka aikin yanke zai zama ƙasa.

2: Tushen lu'u-lu'u mai sanyi-magu.

Ana sarrafa irin wannan nau'in zato ta hanyar latsa sanyi da ɓacin rai. Saboda matsalolin fasaha, jikin ruwa da kuma kan ɓangaren tsinken tsintsiya a haƙiƙa suna haɗuwa tare. Tunda akwai wuraren haɗin kai da yawa a tsakanin su biyun, kuma akwai ƙarancin kayan haɗin da suka dace a tsakanin su biyun, yayin da ake sarrafa su, idan ƙarfin sarrafawa ya yi yawa, yana da sauƙi haƙoran tsintsiya su tashi. A saboda wannan dalili, ana amfani da igiyar gani na abubuwan da aka shigar da sanyi a cikin kayan aikin gani da diamita na ƙasa da 230mm. A cikin aikin sarrafa dutse, ana amfani da irin wannan nau'in zato a cikin kayan aikin hannu, kamar injin niƙa na hannu, injin yankan hannu da sauran injuna. Har ila yau, akwai wasu abokan ciniki na Vietnamese waɗanda ke amfani da igiya na 230mm don yanke shingen dutse tare da ƙayyadaddun bayanai. Baya ga matsalolin jinkirin yadda ya dace da ƙarancin amfani da ruwa, farashin naúrar yana da arha, kuma fa'idodi da yawa kamar babu walƙiya kuma suna yin irin wannan nau'in tsinken tsintsiya a cikin shingen dutse da amfani sosai a cikin aiwatarwa.

3: High mita waldi lu'u-lu'u abun da ake sakawa saw ruwa.

Irin wannan nau'in zato ana welded ne don shigar da sashin lu'u-lu'u akan gindin tsinken, kuma bangaren lu'u-lu'u galibi ana yin shi ne ta hanyar latsawa mai zafi da rarrabuwa. Ta hanyar siyar da mitoci mai yawa, ana ƙara solder a kan mai yankan da ga gindin ruwa, wanda galibin fakitin siyar da tagulla ne, fakitin siyar da azurfa, ko wani magudanar ruwa. Wannan tsintsiya madaurinki yana da sifofi kamar haka: Na farko, ana iya yi masa walda a kan wani babban baga mai girma, wanda zai iya tabbatar da cewa za a iya amfani da babban dutse mai girma don yanke dutse, kuma yana iya yanke manyan tubalan. Na biyu, ana iya maye gurbin ɓangaren lu'u-lu'u da sauri, wanda zai iya magance matsalar da sauri na lalacewa na lu'u-lu'u. Lokacin da aka maye gurbin sashe na lu'u-lu'u, ana iya sake amfani da tsintsiya madaurinki ɗaya, wanda ke adana tsadar canji mai tsada na tushe mai tsintsiya. Na uku, babban ƙarfin walƙiya mai girma yana da girma. Idan ana amfani da tab mai ma'ana da solder don waldawa, ƙarfin walda na ɓangaren lu'u-lu'u yana da yawa sosai. Idan babu yanayin zafi mai zafi, tasirin tasiri da juriya na lankwasawa na wannan saka yana samuwa kuma ya dace da duk yankan dutse. Na hudu, farashin injunan walda a halin yanzu ba su da yawa, kuma yana da sauki wajen gudanar da aikin sarrafa walda, kuma masana'antar za ta iya gane yanayin sarrafa walda mai zaman kanta a farashi mai rahusa.

4: Laser lu'u-lu'u abun saka saw ruwa.

Irin wannan nau'in zato yana dumama sassan bangon bangon babur da sassan lu'u-lu'u ta hanyar Laser, kuma waɗannan wurare guda biyu suna wucewa ta yanayin zafi don ƙirƙirar sabbin kayan gami. Ƙarfin wannan kayan haɗin gwal yana da girma fiye da na kayan walda,ko da sau da yawa mafi girma, don haka babbar amfani da wannan Laser takardar ne cewa waldi ƙarfi ne high, kuma zai iya yanke wasu wuya kayan. Misali, ana iya yanke siminti mai ƙarfi, yankan tama na ƙarfe da sauransu, ta wannan hanyar yanke. A cikin sharuddan dutse aikace-aikace, saboda gaskiyar cewa Laser takardar ne a kan aiwatar da waldi, shi a zahiri ya sa wasu kadan nakasawa ga takardar jiki, kuma yana da wuya a rike a daga baya disassembly aiwatar da lu'u-lu'u kashi. Sabili da haka, a cikin masana'antar sarrafa dutse, ƴan masana'antun suna amfani da wannan hanya. Sai dai idan akwai buƙatun yankan na musamman, kamar yanke bushewa, kamar tsananin taurin dutse, da sauransu, a cikin waɗannan lokuta na musamman, ana iya amfani da takardar walda ta Laser don yanke dutsen.

5: Brazing da electroplating lu'u-lu'u saw ruwan wukake.

An gabatar da fitattun kayan gani na lu'u-lu'u ta hanyar sanya lu'u-lu'u a kan ma'aunin tsintsiya, kuma har yanzu ana iya amfani da wannan hanyar don tunani. Ana gyara lu'u-lu'u a saman tsinkar ta hanyar yin amfani da lantarki da vacuum brazing, kuma ana kammala aikin yanke dutsen da lu'u-lu'u a saman katakon. Ana amfani da irin wannan nau'in zato mafi yawa don bushewar dutse, musamman don yanke inganci. Irin wannan nau'in tsintsiya na iya inganta ingantaccen aikin yankewa kuma yanayin waje bai shafe shi ba.

A ƙarshe, abin da aka saka lu'u lu'u-lu'u yana da mahimmanci ga yanke dutse. Ana iya cewa abubuwan da aka saka dutse na iya saduwa da kusan dukkan buƙatun yankan dutse, kuma aikin waɗannan igiyoyin gani za su sami babban ƙarfin ci gaba a nan gaba.