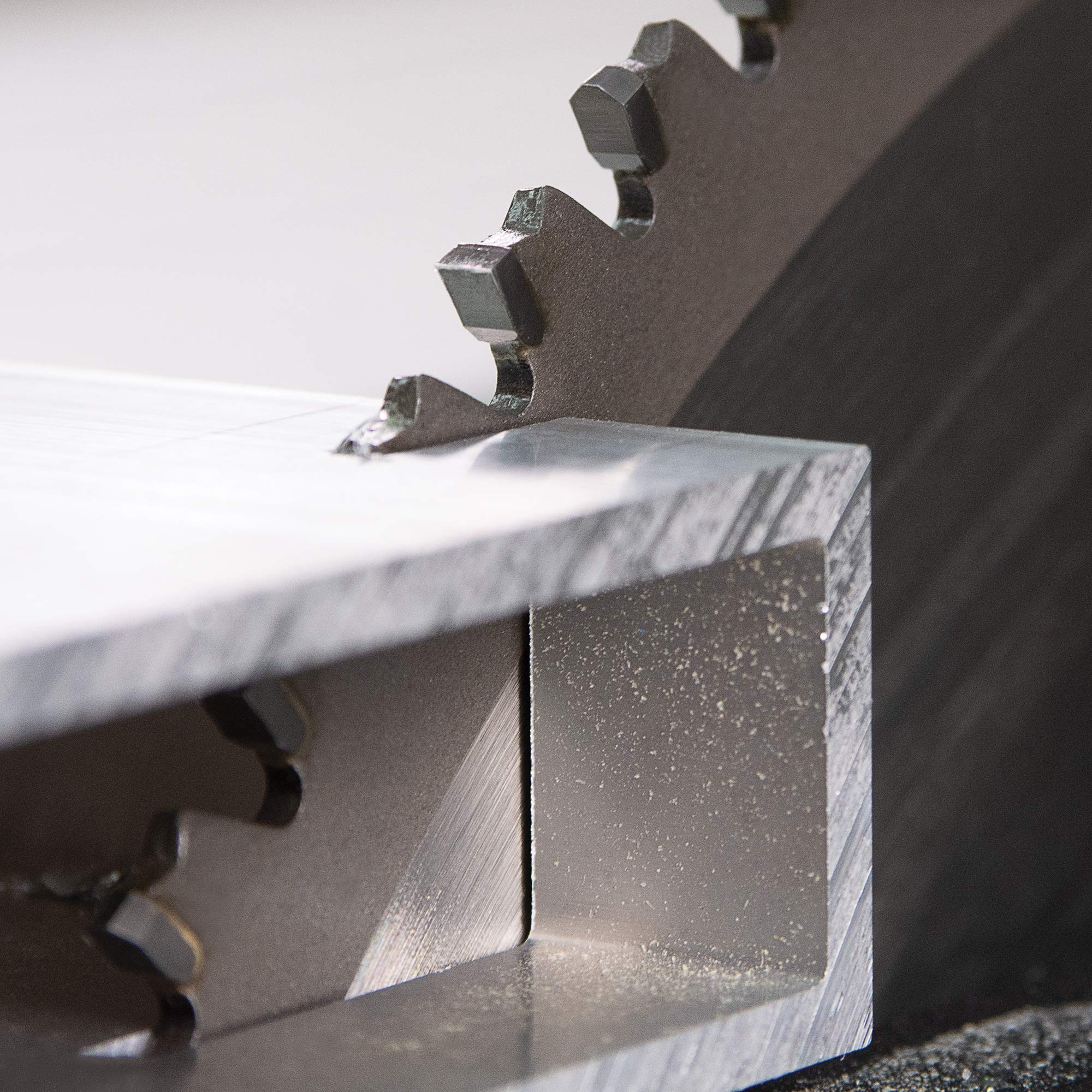

Aluminum yankan saw ruwan wukake yawanci amfani da kayan aikin yankan don sarrafa aluminum, kuma ingancin simintin carbide saw ruwan wukake yana da alaƙa da ingancin samfuran da aka sarrafa. Yana da wani carbide-tipped madauwari saw ruwa musamman amfani da blanking, sawing, milling da tsagi na daban-daban aluminum gami kayan.

A lokaci guda, aluminum yankan saw ruwan wukake wani nau'i ne na kayan amfani. Lokacin da sautin yana da ƙarfi a lokacin yankan kuma akwai burrs akan aikin yankan, yakamata a maye gurbin igiyoyin gani. Don haka yadda za a maye gurbin sawduka daidai?

1. Tsaftace bayan farantin matsi na ciki don hana cakuɗen zaƙi da yankan mai daga ƙarfafawa da mannewa a baya. Wannan na iya hana igiyar zato daga dumama saboda juzu'i da zafi kuma yana shafar damuwa, yana haifar da zawar ruwan wurwuri kuma ta kasa yin aiki akai-akai.

2. Abu na biyu, ya kamata a tsabtace farfajiyar farantin ciki da farantin karfe. Kada a samu tarkacen aluminum da sauran su, domin idan akwai tarkacen aluminium da sauran abubuwa a cikinsa, zai yi tasiri ga yankan alluminum bayan sanya tsintsiya madaurinki daya. A flatness na ruwa a lokacin da yankan, sakamakon a burrs da ga alamomi a lokacin da workpiece ne yanke da aluminum saw ruwa.

3. Bayan kwatanta, bayan shigar da sabon aluminum yankan saw ruwa ko alloy nika disc, ya kamata ka duba ta gefen tare da bugun kira nuna alama. Lokacin da igiya da farantin matsi sun kasance na al'ada, sabon tsinken gani yana bugun 0.06, kuma diski mai niƙa Ya kamata ya kasance tsakanin 0.06 da 0.1. Tabbas, ya kamata kuma a duba igiya da farantin matsa lamba akai-akai don tabbatar da cewa kayan aikin sun kasance na yau da kullun.

Abin da ke sama shine hanyar aiki na dubawa da maye gurbin katakon yankan aluminum. Tabbas, ƙayyadaddun halin da ake ciki ya dogara da matsayin aiki na kayan aikin injin yankan yankan aluminium.