Vim li cas cov saws tshiab tsis zoo li qub sawb tom qab hloov nrog lub tshuab? Raws li cov neeg siv kev tawm tswv yim, muaj glitches, suab nrov, thiab ntxhib ntuag nto. Cov teeb meem no yog vim li cas? Tus editor hauv qab no yuav qhia koj tias vim li cas qhov xwm txheej no tshwm sim thiab yuav daws nws li cas.

Vim li cas cov saws tshiab tsis zoo li qub sawb tom qab hloov nrog lub tshuab? Raws li cov neeg siv kev tawm tswv yim, muaj glitches, suab nrov, thiab ntxhib ntuag nto. Cov teeb meem no yog vim li cas? Tus editor hauv qab no yuav qhia koj tias vim li cas qhov xwm txheej no tshwm sim thiab yuav daws nws li cas.

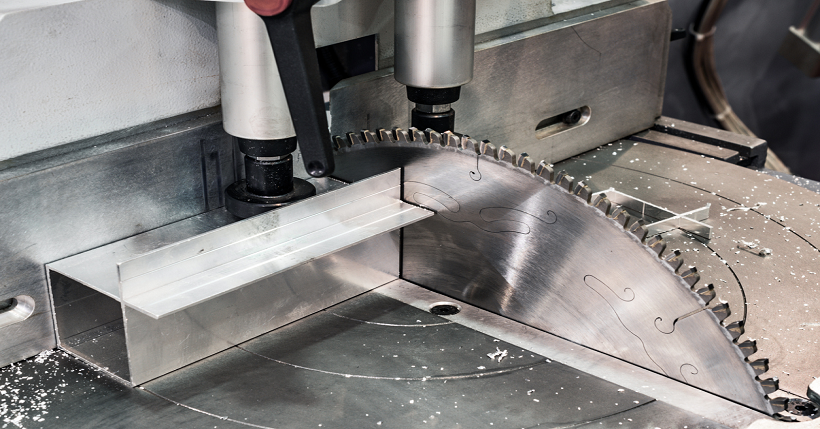

Yog vim li cas 1: spindle yog laus thiab hnav; xyuas qhov khiav tawm ntawm lub spindle ua ntej hloov cov saw hniav. Yog hais tias lub runout ntau tshaj qhov tsim nyog, lub sawb yuav deflect, uas ua rau burrs ntawm sawed workpiece. Nws yog ib qho tsim nyog yuav tsum tau nres lub sijhawm ua haujlwm thiab hloov cov spindle.

Yog vim li cas 2: Muaj cov khoom txawv teb chaws ntawm lub flange; Raws li lub npe qhia, muaj cov khoom txawv teb chaws ntawm lub flange, uas txhais tau hais tias muaj txhuas chips thiab stains ntawm lub phaj siab uas kho cov saw hniav, saw hniav tsis tau ntsia rau lub sij hawm no lub sawing workpiece kuj yuav muaj burr, nrov tshwm sim. , yog li tus editor qhia tias koj yuav tsum kuaj xyuas lub flange kom tsis txhob muaj kev thauj khoom thib ob thiab tshem tawm ntawm cov saw hniav.

Yog vim li cas 3: Seb cov roj lubricating txaus; ib tug series ntawm kev npaj ua hauj lwm yuav tsum tau ua ua ntej txhim kho lub sawb. Lubricating roj yog ib txoj haujlwm tseem ceeb. Siv cov roj lubricating tuaj yeem txo qhov kev sib txhuam ntawm cov hniav thiab cov khoom ua haujlwm kom tsis muaj qhov pom ntawm cov sawing nto marking kuj prolongs lub neej kev pab cuam ntawm saw hniav.

Yog vim li cas 4: Lub sij hawm hloov lub rooj tsavxwm bakelite uas tau hnav thiab deformed vim kev ua haujlwm ntev. Yog tias lub rooj tsavxwm bakelite tau hnav, nws yuav ua rau txoj haujlwm ntawm cov khoom hloov pauv tom qab lub workpiece raug txiav, thiab cov saw hniav yuav cheb rab riam tiag tiag thaum lub sij hawm rov qab riam (kov cov khoom), ua rau glitches.