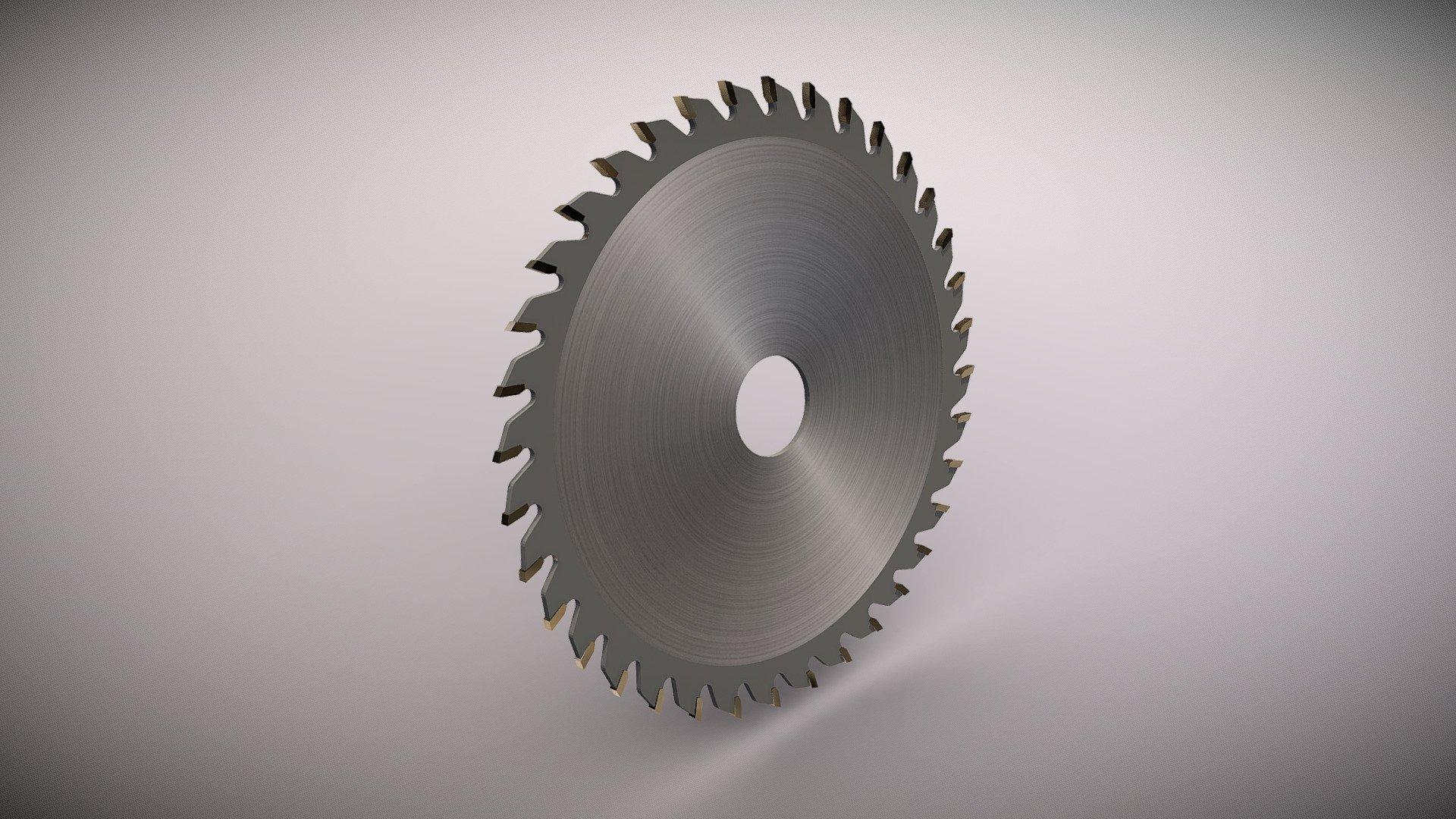

Ntau tus neeg muas zaub tsis quav ntsej txog qee qhov "me me txhais tau tias" los tswj thiab tiv thaiv cov saw hniav thaum siv cov saw hniav, ua rau tib lub saw hniav muaj kev ntsuam xyuas sib txawv ntawm tes ntawm cov neeg siv khoom sib txawv.

1. Yog tias tsis siv cov saw saw tam sim ntawd, nws yuav tsum tau muab tso rau hauv lub tiaj los yog dai ntawm qhov siv lub qhov hauv. Tsis txhob tso lwm yam khoom los yog nqis rau ntawm lub saw saws, thiab xyuam xim rau cov dej noo thiab corrosion.

2. Thaum lub sawb tsis ntse lawm thiab txiav nto yog ntxhib, nws yuav tsum tau reground nyob rau hauv lub sij hawm. Kev sib tsoo tsis tuaj yeem hloov lub kaum sab xis qub thiab rhuav tshem qhov sib npaug dynamic.

3. Txoj kab uas hla sab hauv kho thiab qhov chaw ua haujlwm ntawm cov saw hniav yuav tsum tau ua los ntawm lub Hoobkas. Yog tias kev ua haujlwm tsis zoo, nws yuav cuam tshuam rau kev siv cov khoom siv thiab yuav ua rau muaj kev phom sij. Nyob rau hauv txoj cai, lub reaming qhov yuav tsum tsis txhob tshaj qhov thawj lub qhov taub ntawm 20mm, thiaj li tsis mus cuam tshuam qhov sib npaug ntawm kev ntxhov siab.

Plaub. Alloy sib tsoo log xaiv.

1) Lub zog sib koom ua ke ntawm cov pob zeb diamond sib tsoo lub log tsis muaj zog, yog li tus kheej-ntse tuaj yeem ua tau zoo thaum sib tsoo, nws tsis yooj yim rau clog, kev sib tsoo efficiency siab, sib tsoo quab yuam me me, thiab sib tsoo kub yog qis. Qhov tsis zoo yog kev hnav tsis zoo thiab hnav tsis zoo Loj, tsis haum rau kev sib tsoo hnyav.

2) Vitrified daim ntawv cog lus pob zeb diamond sib tsoo lub log tau zoo hnav tsis kam thiab kev sib koom ua ke muaj peev xwm tshaj li cov ntawv cog lus, kev txiav ntse, kev sib tsoo siab, tsis yooj yim los tsim kom sov thiab txhaws, tsawg thermal expansion, yooj yim los tswj precision, tsis zoo yog ntxhib sib tsoo nto thiab tus nqi siab. .

3) Cov hlau nplaum pob zeb diamond sib tsoo lub log muaj lub zog sib khi zoo, hnav tsis kam, hnav tsis kam, lub neej ntev, kev sib tsoo tsis tshua muaj nqi, thiab tuaj yeem tiv taus cov khoom loj, tab sis muaj qhov tsis zoo thiab yooj yim rau txhaws.

4) Lub abrasive particle loj muaj qee yam cuam tshuam rau qhov txhaws thiab txiav lub peev xwm ntawm lub log sib tsoo. Piv nrog rau cov nplua grit, cov ntxhib grit yuav ua rau kom hnav ntawm ntug txiav thaum txiav qhov tob yog loj, txwv tsis pub lub sib tsoo log yog yooj yim rau clog.

5) Lub hardness ntawm lub log sib tsoo muaj kev cuam tshuam zoo rau kev txhaws. Lub siab hardness ntawm lub sib tsoo log muaj ib tug siab thermal conductivity, uas yog tsis conducive rau saum npoo tshav kub dissipation, tab sis nws yog ib qho zoo los txhim kho kev raug thiab durability.

6) Qhov kev xaiv ntawm kev sib tsoo lub log yog qhov tseem ceeb, uas muaj kev cuam tshuam zoo rau kev sib tsoo thiab kev ua cov nqi. Yog tias qhov concentration tsawg dhau, qhov ua tau zoo yuav raug cuam tshuam. Txwv tsis pub, cov nplej abrasive yuav poob yooj yim, tab sis qhov zoo tshaj plaws daim ntawv cog lus concentration ntau kuj zoo.