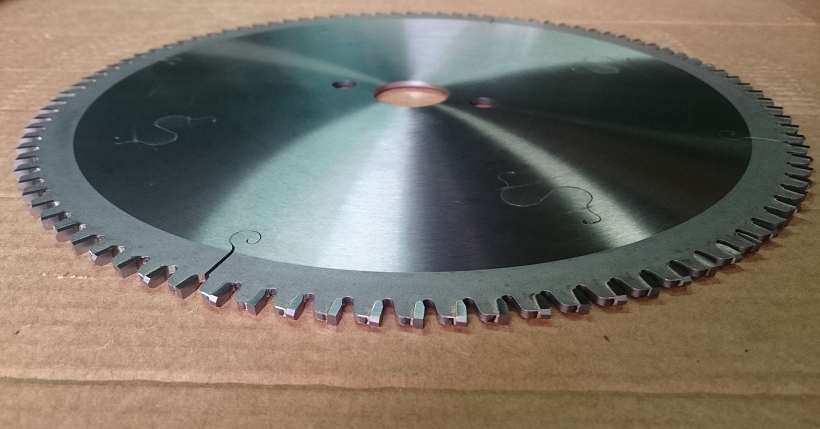

Circular Saw Blade Nta thiab cov ntaub ntawv

Peb cov khoom xaiv muaj qhov zoo tshaj plaws saws saws muaj nyob rau hauv portable, cordless thiab ntawv sau saws. Cov hniav pom muaj nyob rau hauv kev teeb tsa rau feem ntau cov ntawv thov, los ntawm cov hom phiaj dav dav mus rau cov qauv tsim tshwj xeeb. Txhua yam nyob ntawm seb koj xav tau ntau npaum li cas, thiab qhov ntawd feem ntau yog cov lus nug ntawm cov khoom siv thiab kev siv ntau npaum li cas.

Circular Saw Hniav thiab Cov ntsiab lus:

Hauv qab no yog cov npe ntawm Circular Saw Blade cov ntsiab lus thiab cov duab kos los pab koj xaiv cov hniav zoo rau txoj haujlwm zoo:

Anti-kick Saw Blades:Ib qho tshwj xeeb Circular Saw Blade's (CSB) lub xub pwg tsim uas yog tsim los txhim kho qhov yooj yim ntawm kev txiav thiab txo cov nyhuv ntawm cov saw hniav ncaws rov qab vim overfeeding. Arbor: Lub saw motor ncej uas tig cov saw hniav. Feem ntau hu ua mandrel.

Npog:Lub arbor uas lub saw saw yog mounted rau ntawm saw. Muaj nyob rau hauv ntau qhov ntau thiab tsawg. Bore loj ntawm cov hniav.

Bevel:Lub kaum sab xis ntawm tus hniav carbide CSB. Cov hniav tuaj yeem muaj ib qho bevel, ob bevel lossis tsis muaj bevel. Hom bevels tuaj yeem hloov los ntawm cov hniav mus rau cov hniav ntawm cov hniav muab. Lub bevel yog dab tsi muab cov hniav nws tshwj xeeb txiav qauv.

Chipper: Ib qho cuab yeej txiav uas muab tso rau nruab nrab ntawm cov hniav sab nraud ntawm dado teeb tsa los kho qhov dav ntawm qhov txiav.

Chiping:Qhov xwm txheej tshwm sim thaum lub saw hniav nqa thiab ua kua muag ntawm cov ntoo fibers thaum nws tawm ntawm cov khoom. Qhov no ua rau cov npoo yuav ragged.

Txheej: Tshwj xeeb formulated coatings nyob slick. Txheej ib rab hniav txo cov cua sov hauv 2 txoj kev. Nws minimizes kev sib txhuam thiab khi thiab resists suab thiab cov pos hniav buildup.

Combination Saw Hniav:Pom cov hniav siv rau ob qho tib si ripping (txiav nrog cov nplej ntawm ntoo) thiab hlais (txiav hla cov nplej).

Crosscut: Txiav los yog pom tawm tsam / hla cov nplej ntawm ntoo. Cutter: Sab nraum cov hniav siv hauv dado hniav.

Expansion slots: Qhov chaw uas tso cai rau cov hniav kom nthuav dav thaum nws sov thaum txiav. Nws tshem tawm warpage los ntawm txias cov hniav.Ferrous:Los yog muaj hlau.

Finishing Saw Hniav:Ib tug saw hniav nrog ib tug ntau dua cov hniav kom muab smoother txiav. Feem ntau hais txog 7 1/4 nti hniav nrog ntau tshaj 40 hniav thiab 10 nti hniav nrog ntau tshaj 60 hniav. Framing Saw Hniav: Carbide tipped saw hniav siv los txiav ceev hauv txhua hom ntoo (qhov ceev tshaj plaws yog ua tiav nrog cov hniav qis dua).

Kerf:Qhov no yog qhov dav ntawm kev txiav, nrog rau cov hlau phaj thickness ntxiv rau ib qho overhang ntawm lub carbide hniav.

General Purpose Saw Blades: Txo cov hniav suav saw hniav. Feem ntau yog siv rau kev ceev hla txiav thiab ripping.

Gullet: Qhov chaw nruab nrab ntawm cov hniav uas tshem tawm cov khoom ua haujlwm lossis cov chips tom qab txiav.

Sib tsoo: Muaj ntau ntau hom hniav grinds, qee qhov ntawm cov hauv paus yog:

Flat Top Sib Tsoo (FTG)- Qhov zoo tshaj plaws rau ripping.

Alternate Top Bevel (ATB)- rau crosscutting, txiav tawm thiab trimming.

Triple Chip Sib Tsoo (TCG)- Zoo meej rau cov khoom siv tawv tawv xws li cov hlau tsis muaj hlau, tawv ntoo thiab yas.

Tri-Grind (TRI)- Kev sib xyaw ua ke

Hollow av: Ib qho concave bevel ntug ntawm ib lub cuab yeej.

Hook angle: Qhov "tawm tsam" ntawm cov hniav. Nyuaj, cov ntaub ntawv nkig ntau xav tau lub kaum sab xis kom yooj yim rau cov ntaub ntawv thiab txo cov nti tawm. Soter cov ntaub ntawv xav tau lub kaum ntse ntse kom txo cov nti tawm.

Miter: Cov txheej txheem ntawm kev txiav cov khoom siv rau kev sib npaug ntawm lub kaum sab xis. Nonferrous: Cov ntaub ntawv los yog hlau tsis yog los yog muaj hlau, xws li txhuas, tooj liab, tooj dag thiab txhuas.

Phaj: Lub cev steel ntawm carbidehniav uas cov hniav yog welded. Dav Hlau: Hauv kev ua haujlwm ntoo, ua kom lub ntsej muag du lossis txawm.

Luav: Ib qho qhib-kawg txiav ua raws ntug ntawm ib daim ntawv ua haujlwm uas tau txais lossis cuam tshuam nrog lwm daim los ua ib qho kev sib koom ua ke.

Ripping: Cov txheej txheem ntawm sawing ib lub rooj tsavxwm nyob rau hauv cov kev taw qhia ntawm lub grain ntawm lub rooj tsavxwm.

Khiav tawm:Tus nqi ntawm sab laug mus rau txoj cai txav sawb ua thaum lub sijhawm ua haujlwm. Feem ntau hu ua wobble los yog warp.

Stiffening dab tshos:Ib tug ca caj dab uas mounts rau ntawm saws arbor ncaj nraim ntawm cov hniav. Lawv yog siv los ua kom raug txiav ntau dua thiab ua kom lub suab ntawm cov saw generates.

Xim: Ib qho nyias, feem ntau tapered cov khoom xws li hlau los yog ntoo siv los sau rau hauv qhov chaw nruab nrab ntawm cov khoom. Hauv kev ua haujlwm dado, ib puag ncig disk siv los txiav qhov dav.

Ua kua muag:Ib qho xwm txheej uas cov saw hniav ua kua muag tawm ntawm cov nplej ntawm ib qho haujlwm.

Tempered:Txhawm rau nqa cov hlau phaj ntawm sawb mus rau qhov xav tau hardness los ntawm kev rov ua kom sov thiab txias.

Nyias kerf saw hniav: Ib tug saw hniav nrog ib tug txo kerf, los yog txiav dav.