Can a diamond saw blade cut steel? Many diamond saw blades seem to many people who do not understand this industry. Diamond is so powerful that it must be able to cut any material. In fact, it's not true.

First of all, let's talk about the structure of diamond saw blades. Some saw blades use cold-press sintering to fix the base and the diamond segment together. Such saw blades are often relatively small, and the general size is between 105-230mm. This cold-pressed saw blade can be divided into general-purpose saw blade, tile sheet, stone sheet, asphalt sheet and so on according to the cutting object.The general-purpose saw blade is well understood, that is, any product can be cut, but the effect of cutting anything will not be too excellent. In conclusion, it is barely usable. This kind of saw blade can be used to cut some fine steel. It is best not to use this saw blade for cutting too thick and hard steel. The main reason is that some segments will fall off due to the high cutting strength of the sheet body or segment, and the sheet body will be bent or broken, resulting in dangerous accidents. As for other diamond saw blades, such as stone chips, they cannot be used to cut steel bars.

In addition to the above cold-pressed sintering structure, a high-frequency welding structure is more commonly used in the stone industry, but the diamond saw blades produced are often only used for cutting stone, and other materials are easy to cut the segment.

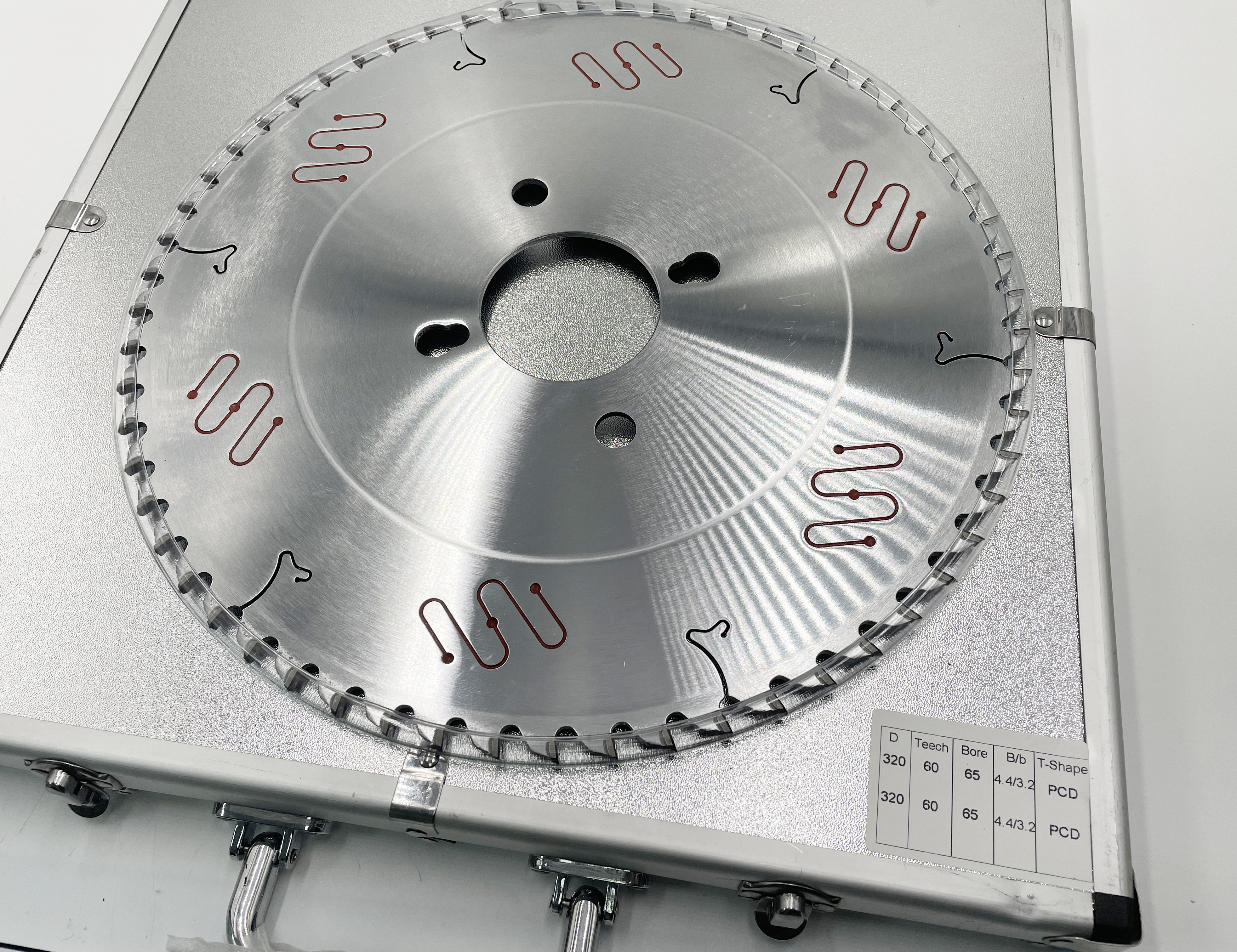

Usually used for cutting steel belongs to another structure - laser welding saw blade, People call this type of saw blade as a road blade. As the name suggests, it is used to cut the road. The diameter of the saw blade ranges from 250-1200mm. This type of saw blade adopts the method of laser welding, and the high temperature resistant cutter head is welded to the saw blade by laser. Cutting ability, so this type of saw blade can cut steel bars, especially for reinforced concrete, it has a good sawing effect.

There is also a type of saw blade that belongs to vacuum brazed diamond saw blade. This type of saw blade has different diamond fixing methods, so the biggest performance in the cutting process is fast. Although the cutting performance is relatively strong, it is also not suitable for steel with high hardness.

Secondly, the diamond saw blade head for cutting iron also needs to be specially customized. For example, it needs to be adjusted in terms of wear resistance and diamond concentration, as well as diamond grade. For example, finer diamond particles are required, the concentration of diamond should be increased, and the hardness should be enhanced, etc. Then the steel can be cut.

In addition, the diamond saw blade needs to cut steel, and the shape of the segment must be adjusted. At present, the single-sided corrugated tooth saw blade is widely used in the road cutting saw blade. This shape of the segment can greatly increase the sharpness of the saw blade, but the requirements for the wear resistance of the carcass and the impact resistance are extremely high, otherwise the segment will easily fall off or be consumed too quickly, resulting in cutting problems.

Finally, when cutting steel, we must pay attention to the changes in the cutting performance of the saw blade, and constantly adjust the cutting speed. After the problem is solved, continue to cut, and in the process of cutting steel, be sure to control the length of a single cut to prevent the saw blade from overheating.

In general, diamond saw blades are not recommended for long-term cutting of steel, and grinding wheels are better than diamond saw blades.