Classification of metal sawing machines

As a very important part of the metal forming process, metal cutting plays a vital role in industrial production. The mechanical equipment used in the metal cutting process is Metal Cutting Saws.

Metal sawing machine is one of the important metal cutting machine tools, accounting for about 6-10% of the total amount of metal cutting machine tools in various fields of global industrial production. It uses the relative movement of the multi-tooth tool and the workpiece to realize sawing or contour forming of various metal materials.

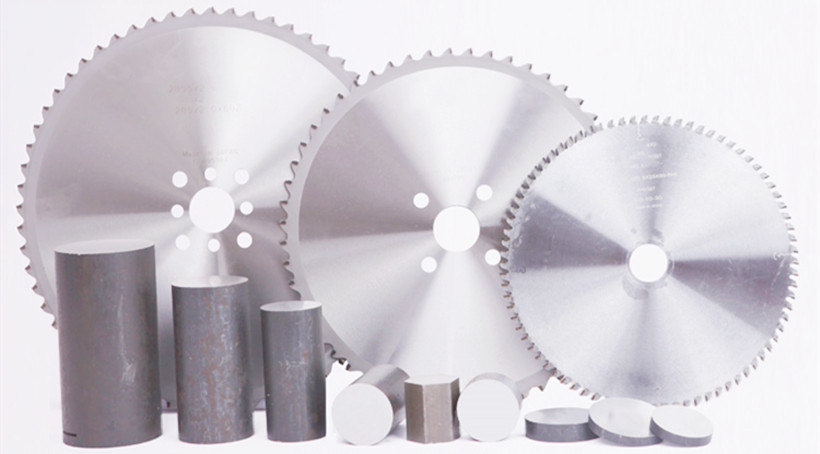

Metal sawing machines can be divided into grinding saws, band saws, and cold saws.

Grinding wheel saw use high-speed rotating grinding wheels to cut steel. It is suitable for construction, hardware, petrochemical, mechanical metallurgy, hydropower installation and other departments. It can cut metal square flat tubes, square flat steels, I-beams, channel steels and other materials.

The grinding saw is mainly composed of a base, a grinding wheel, a motor or other power source, a bracket, a protective cover, a water feeder, etc. The grinding wheel is set on the top surface of the base, and the base corresponds to the bottom of the grinding wheel. It is located above the side of the grinding wheel.

Grinding wheel saw is also called grinding wheel saw. They use high-speed rotating grinding wheels to cut steel. It is suitable for construction, hardware, petrochemical, mechanical metallurgy, hydropower installation and other departments. It can cut metal square flat tubes, square flat steels, I-beams, channel steels and other materials.

The grinding saw is mainly composed of a base, a grinding wheel, a motor or other power source, a bracket, a protective cover, a water feeder, etc. The grinding wheel is set on the top surface of the base, and the base corresponds to the bottom of the grinding wheel. It is located above the side of the grinding wheel.

The metal belt of the band saw is set vertically between the two large wheels, which can be used to cut irregular shapes. The radius of the saw curve is determined by the thickness of the blade. In the metal sawing process, the heat generated by the saw blade saw tooth sawing the workpiece will be transferred to the sawdust through the saw tooth, and the sawed workpiece and saw blade are kept cool.

Cold sawing is the use of cold milling sawing, sawing process generates little heat, you can avoid internal stress and material organization changes at the cut section, while the pressure of the saw blade on the steel pipe is very small, will not cause deformation on the pipe wall and pipe mouth.

The choice of the way to cut metal is mainly based on the cutting requirements for the surface of the workpiece. If you have any questions, please contact us and our professional technicians will answer for you.

E-mail: info@donglaimetal.com