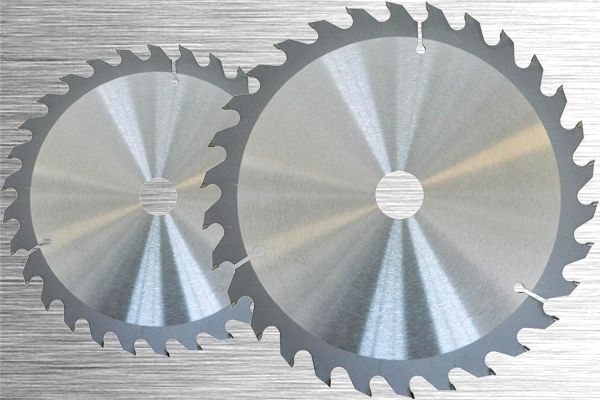

Diamond saw blades often have some problems during use. How to solve these problems when they occur? Please see the summary of the editor.

1. The thickness of the cut plate is uneven

(1) The basic tension is not suitable; the tension of the saw blade needs to be corrected again.

(2) The screws of the screw bearing seat of the fixed trolley are loose; adjust the rotating screw.

(3) The diameter of the guide rail is poor in levelness; if tested by the method of pulling wires, the degree of deviation should be adjusted between 0.5mm and the levelness should be less than 1mm.

(4) The screw nut has a large gap, and the operation does not eliminate the gap; pay attention to remove the gap in one direction during operation.

(5) The phenomenon that the screw nut is not clamped tightly and shakes; tighten the clamping nut.

(6) The guide wheels are inconsistent; loosen the nuts and re-adjust them to be consistent.

(7) The saw blade end skips too much; level the saw blade and pass the test.

(8) The welding between the cutter head and the substrate is asymmetrical; re-weld or replace the saw blade.

(9) The cut block is less than 0.5 cubic meters; the block should be larger than 0.5 cubic meters.

(10) The transmission chain is too loose; adjust the chain tightness.

2. The machine shakes excessively during operation

(1) The clearance of the main bearing is too large; open the adjustment nut of the iron sheet cover of the headstock.

(2) The spindle bearing is damaged, resulting in unstable operation of the saw blade; disassemble the spindle box to check the spindle bearing, and replace it with a new one.

(3) The radial runout of the saw blade is too large; check the radial runout of the saw blade and replace it.

3. The head height of the saw blade is inconsistent after use

(1) The clearance of the main shaft bearing is too large; open the iron cover of the main shaft box to adjust the nut.

(2) The precision of the radial jump over the large central hole is out of tolerance; the accuracy is out of tolerance