Diamond insert saw blade are one of the more commonly used saw blades. The biggest feature of this saw blade is that some inserts are inlaid on the saw blade through various processes in the later stage. This saw blade is widely used in stone and concrete cutting industries. This article introduces the different performances of various diamond insert saw blades by introducing the specific characteristics of the diamond insert saw blades.

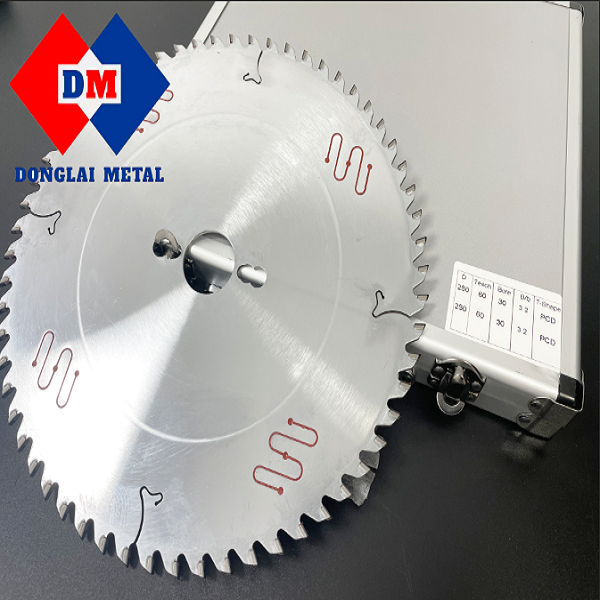

1: PCD diamond insert saw blades.

This type of saw blade is mainly used for wood cutting, and can also be used for stone processing. The biggest feature of this type of saw blade is that the insert is similar to that of TCT, but the difference is the insert part of the saw blade. The inserts are made of hard alloy, and the process used by the PCD insert saw blade is that some PCD composite sheets need to be welded on the saw blade. At the same time, the service life of the insert can also be further improved. Stones are rarely processed by PCD. The first reason is that the price of PCD composite sheets is high, and the diamond exposure problem, so the cutting efficiency will be low.

2: Cold-pressed diamond insert saw blade.

This type of saw blade is processed by cold pressing and sintering. Due to technological problems, the blade body and the head part of the saw blade are actually sintered together. Since there are not too many connecting surfaces between the two, and there is a lack of suitable connecting materials between the two, during the processing, if the processing strength is too high, it is easy for the saw blade teeth to fly out. For this reason, the saw blades of cold-pressed inserts are mostly used in saw blades with a diameter of less than 230mm. In the process of stone processing, this type of saw blade is more commonly used in hand tools, such as hand-held angle grinders, hand-held cutting machines and other machinery. There are also some Vietnamese customers who use 230mm saw blades for cutting stone slabs with specifications. In addition to the problems of slow efficiency and low utilization rate of the blade, the unit price is cheap, and many advantages such as no welding also make this type of saw blade in stone sawing good use in the process.

3: High frequency welding diamond inserts saw blade.

This type of saw blade is welded to insert the diamond segment on the saw blade base, and the diamond segment is usually produced by hot pressing and sintering. By means of high-frequency soldering, solder is usually added to the cutter head and saw blade base, which is usually copper solder pads, silver solder pads, or some other flux. This saw blade has the following characteristics: First, it can be welded on a larger saw blade blank, which can ensure that a large size saw blade can also be used to cut stone, and can cut larger blocks. Second, the diamond segment can be replaced quickly, which can quickly solve the problem of diamond segment wear. When a set of diamond segments is replaced, the saw blade can still be reused, which saves the expensive replacement cost of the saw blade base. Third, the high frequency welding strength is high. If a reasonable solder tab and solder are used for welding, the welding strength of the diamond segment is very high. In the absence of high temperature conditions, the impact resistance and bending resistance of this insert are available and suitable for all stone cutting. Fourth, the current welding machinery cost is low, and it is easy to carry out welding processing, and the factory can realize the conditions of independent welding processing at a lower price.

4: Laser diamond inserts saw blade.

This type of saw blade heats parts of the saw blade base blank and the diamond segments by means of a laser, and these two areas pass through high temperature to form new alloy materials. The strength of this alloy material is much higher than that of the welding material, even several times higher, so the biggest advantage of this laser sheet is that the welding strength is high, and it can cut some hard materials. For example, reinforced concrete, metal ore body cutting, etc., can be cut by this cutting method. In terms of stone application, due to the fact that the laser sheet is in the process of welding, it actually causes some slight deformation to the sheet body, and it is difficult to handle in the later disassembly process of the diamond segment. Therefore, in the stone processing industry, few manufacturers use this method. Unless there are special cutting requirements, such as dry cutting, such as high hardness of the stone, etc., in these special cases, the laser welding sheet can be used to cut the stone.

5: Brazing and electroplating diamond saw blades.

The earliest diamond saw blades were presented by inlaying diamonds on the saw blade substrate, and this method can still be used for reference. The diamond is fixed on the surface of the saw blade by electroplating and vacuum brazing, and the cutting process is completed by cutting the stone with the diamond on the surface of the saw blade. This type of saw blade is mostly used for dry stone cutting, especially for cutting efficiency. This type of saw blade can greatly improve the cutting efficiency and is not affected by the external environment.

In conclusion, the diamond insert saw blade is of great significance for stone cutting. It can be said that stone inserts can meet almost all cutting needs of stone, and the performance of these saw blades will also have great development potential in the future.