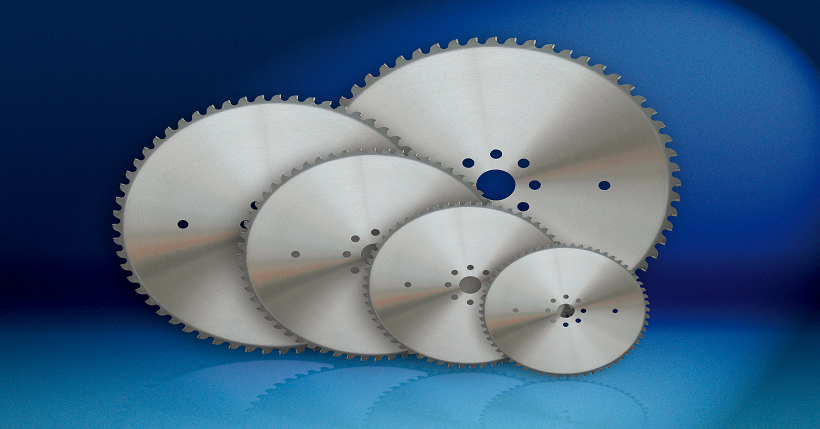

Round blades are usually durable and have good cutting performance, but there will be a certain degree of wear after a long time of use, and this wear is related to the following key factors.

1.Materials

The hard wear resistance of the material used to make the round blade is better, but at the same time the toughness is lower. Hardness and toughness are opposite, which is also an aspect that needs to be improved. If it is a graphite round blade, the material can be selected with better toughness.

2.surface coating

Diamond-coated round blades have the advantages of high hardness, good wear resistance, and low friction coefficient, and are currently an ideal production method. However, the production cost is relatively high, and the current domestic technology in this area is not yet mature enough. Graphite-coated round blades are widely used and practical.

Therefore, if you want to reduce the wear of the round blade, you can give priority to the material and coating.