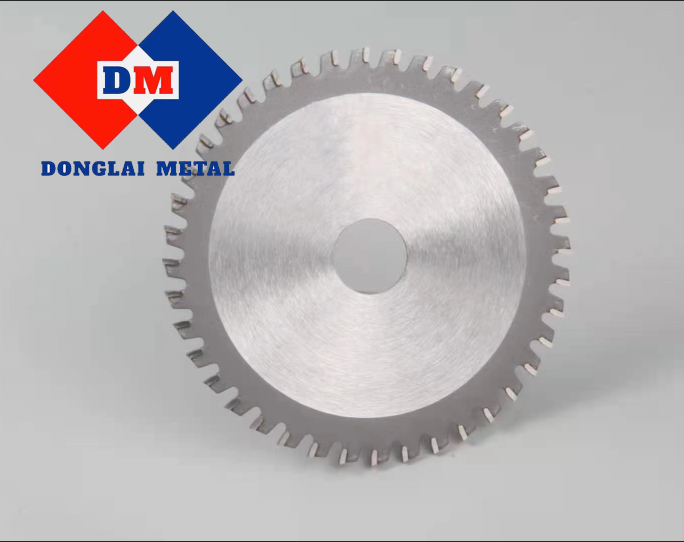

The cold saw metal circular saw blade need specific adjustments and setings in cutting. Some operations on the details can effectively improve the cutting effect and extend the service life of the cold saw metal circular saw blade, including the stability during cutting and the quality of the workpiece .

First, preparatory work

When using cold saw metal circular saw blades, the preparatory work must be done in place, especially the installation of the saw blade.

Preheating and idling must be carried out before use. The so-called preheating and idling refers to the operation of the cold saw metal circular saw blade for a period of time after installation and before use (no need to cut any material, just empty work) , lasts about 1 minute to 10 minutes (the details need to be determined according to the actual situation), if it is a hot climate, it needs to be sprayed with oil mist or water; this will help to enhance the sharpenness of the saw blade, if it is just installed Just carry out the cutting operation directly, which will easily cause damage to the metal circular saw blade.

Second, some precautions when sawing

Some problems must be paid attention to when cold sawing metal circular saw blades are sawing. Do not work carelessly, which may cause permanent damage to equipment and saw blades.

1. After the idling is completed, check the distance between the cold saw metal circular saw blade and the cutting material (commonly known as the saw blade returning to zero), and do not start the operation when the saw blade is in contact with the material.

2. If it is found that the material shakes during the cutting process, the operation must be stopped, and the cutting operation can only be carried out after checking the faults and arranging them. (During the operation, do not move the material, and it is forbidden to touch the saw blade with your hands).

3. When cutting, if you find that the metal circular saw blade of the cold saw slightly shakes or jams, you must stop the equipment immediately. It is likely to be caused by a certain part stuck or a problem with the magnetic powder clutch.

4. If you find problems such as deceleration or reduction in cutting quality during sawing, you should stop running, check the nut or the cutting depth is too large, and the working speed is too fast, check and adjust in time.

When using a cold saw metal circular saw blade for cutting processing, it is necessary to carefully check the important parts.