(3) Diameter

The diameter of the saw blade is related to the sawing equipment and the thickness of the sawed workpiece. The diameter of the saw blade is small, and the cutting speed is relatively low; the diameter of the saw blade is large, and the requirements for the saw blade and sawing equipment are high, and the sawing efficiency is also high. The outer diameter of the saw blade choose the right diameter according to different circular saw machine.

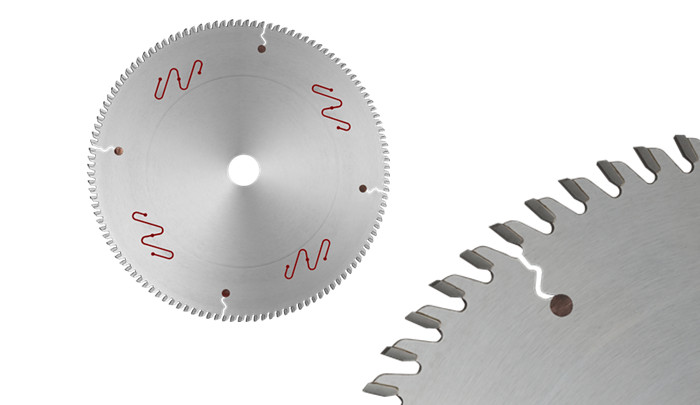

(4)The number of teeth

Generally,the more number of sawteeth, the more cutting ability per unit time, the cutting performance is more better, but the more cutting teeth need to use more carbide, the price of the saw blade is more high.But the sawtooth is too dense,the space of chips is smaller, which will easily cause the saw blade to heat up; In addition, if there are too many saw teeth, if the feed rate is not matched properly, the cutting amount of each tooth will be very small, which will increase the friction between the cutting edge and the workpiece, and affect the service life of the blade.Usually the tooth spacing is 15-25mm, and a reasonable number of teeth should be selected according to the material to be sawed.

(5) Thickness

The thickness of the saw blade In theory, we hope that the thinner the saw blade, the better. The sawing kerf is actually a kind of consumption. The material of the alloy saw blade base and the process of manufacturing the saw blade determine the thickness of the saw blade. If the thickness is too thin, the saw blade is easy to shake when it is working, which will affect the cutting effect. When choosing the thickness of the saw blade, the stability and the cut material should be considered. The thickness required for some special-purpose materials is also specific, and should be used according to equipment requirements, such as grooving saw blades, scoring saw blades, etc.