- Super User

- 2023-04-19

The thickness of the multi-blade saw blade quality plays an important role in th

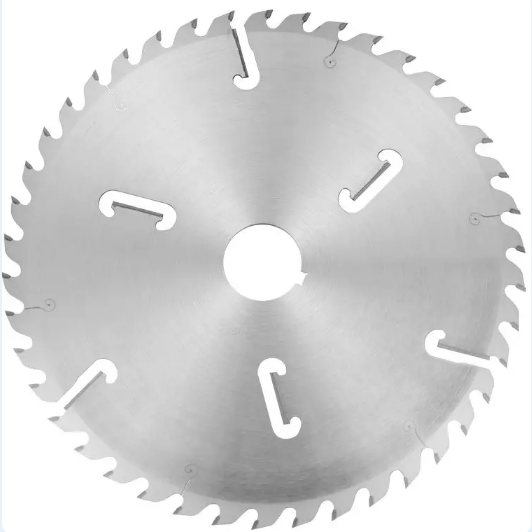

The thickness of the multi-blade saw blade In theory, we hope that the thinner the saw blade, the better. The saw kerf is actually a kind of consumption. The material of the alloy saw blade base and the process of manufacturing the saw blade determine the thickness of the saw blade. If the thickness is too thin , the multi-blade saw blades are easy to shake when working, which affects the cutting effect. Taking the multi-blade saw blade as an example, the thickness of the 110-150MM outer diameter can be 1.2-1.4MM, and the thickness of the 205-230MM outer diameter saw blade is about 1.6 -1.8MM, only suitable for cutting soft wood with low density. When choosing a multi-saw blade thickness, you should consider the stability of the saw blade and the material to be cut.

At present, in order to reduce consumption, some companies have begun to produce multi-saw saw blades with single-sided or double-sided convex plates, , the two sides of the middle hole are thicker, and the inner side of the alloy is thinner, and then the teeth are welded to ensure the cutting thickness. At the same time, to achieve the effect of material saving, the cutting depth is not more than 40MM. Part of the equipment is designed to have the effect of direct trimming, and it is necessary to install a multi-blade saw. The saw blades for trimming are generally thickened saw blades to ensure the smoothness of edge cutting.

The quality of multi-blade saw blades plays a vital role, because everyone knows that multi-blade saw blades in woodworking machinery are adjusted to rotate. It not only transmits cutting force but also maintains working stability. Excellent multi-blade saws The blade not only has static geometric dimensions and accuracy, but more importantly, its dynamic characteristics are particularly good. It has been sharpened many times and has a long service life. The welding quality of cemented carbide is also very important. When multiple saw blades are continuously cutting , so that the temperature of the saw board rises rapidly, and the high-quality saw board can maintain a high standard of precision in this case, while the saw blade with poor quality will warp the saw board, so that the saw teeth can withstand greater cutting Force, the cutting precision of wood is very high.