Why Does My Bandsaw Blade Keep Breaking?

Let’s face it, we ask a lot of our bandsaw blades, and we wonder why they seem to break prematurely. It is true that in many cases we often think that they have failed quickly but when measured against the actual number of cuts they have produced, they have usually served us well. There are many reasons why blades can fracture and you may be breaking blades well before their time.

Here, we look at some of the common reasons for the premature failure that may befall your blades.

Incorrect usage

This can cover a range of problems such as little or no lubricant, inappropriate blade for the material being cut, wrong cutting speeds, or usage when the blade is worn out. This generally tends to cover what can be regarded as misuse. We recommend that you regularly service your bandsaw and ensure it is working at the optimum levels. Training your operator is essential and ensuring that the blade is regularly checked for visible signs of wear before use. If you are in doubt contact our GoldcutTM team who would be more than happy to help.

Running in procedure

Whenever you work a new blade it is essential to run in the blade before commencing a production cycle.

Over tension

Having a tight blade is certainly preferable to one that is loose, since that will raise even more problems. However, over tensioning can introduce a range of other problems which you may not see immediately but this will certainly reduce the life of your blade. Over tensioning can lead to body breakage in the blade, cracks on gullets, or cracks on the back edge. Most new saws come with the built-in tension indicators however, you can purchase a standalone gauge for more accurate results.

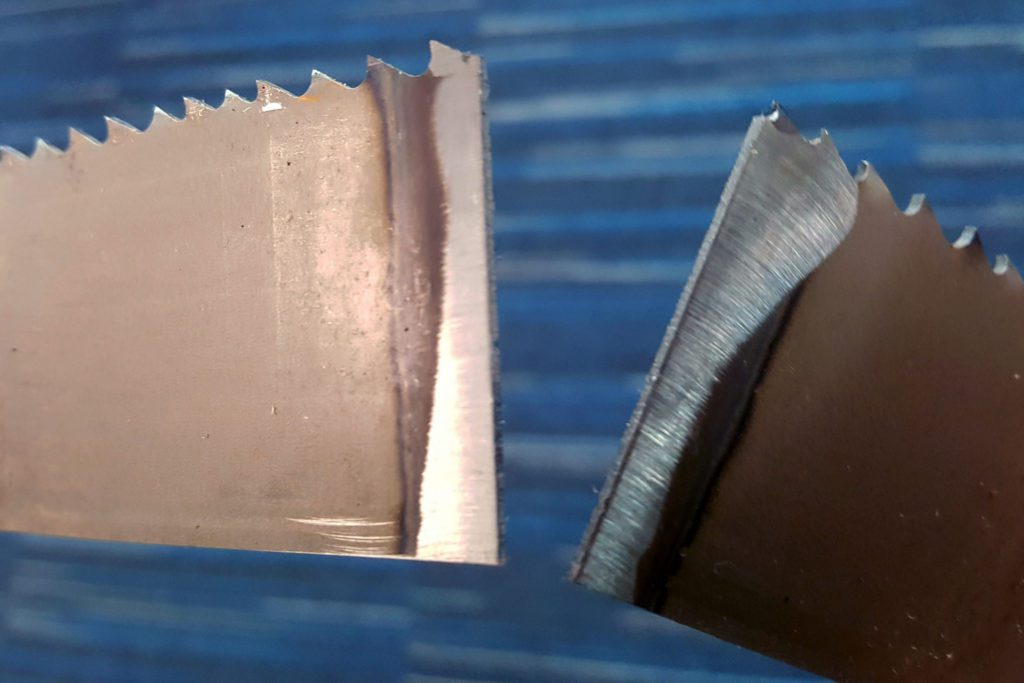

Incorrect tooth pitch

Bandsaw blades differ from hand hacksaw blades in that they are generally heavier, made in longer sizes, and have fewer teeth per inch. Typically, they can range from between 4 and 14 teeth per inch. However, the general rule is at least three full teeth must be on the work piece at any time still applies and to have less will cause a snag and tooth breakage.

Blade at end of life

Even the most well-maintained bandsaw will finally experience failure as the blade wears and as it becomes blunt. The risk of catastrophic failure increases. A blade will normally let you know that it is becoming blunt by an increase in noise, and a corresponding decrease in cutting ability. This might be gradual and you may not notice straight away. Although it will become gradually more apparent. When you do experience this, it’s time to change that blade before it completely fails during the job you are working on. To reduce the chance of any unpleasant surprises we recommend that you plan to change the blade as part of your routine maintenance.

Machine Defects

Even the best blades can fail if there is something else wrong with your bandsaw, and even a small misalignment of bearings or guides can put a twist in the blade as it goes around. Resulting in tension being applied in all the wrong ways which will lead to early breakage. Misalignment tends to put the most stress on the joining weld and making that the primary point of failure. Regular service will help ensure that your blade is properly aligned, and all other components are in good order.

Poor quality blades

Bandsaw blades are not created to be equal, and whilst it is tempting to pay less, economy will never equal quality. If you want to change your blade very regularly, buy cheaper ones, but if you want a blade that will not only last but will deliver premier cuts for its whole life, it is worth spending a little more.

Bandsaw blades are designed to produce perfect cuts time and again, and if used properly, and on a well-maintained machine, you can be assured of a long blade life too.