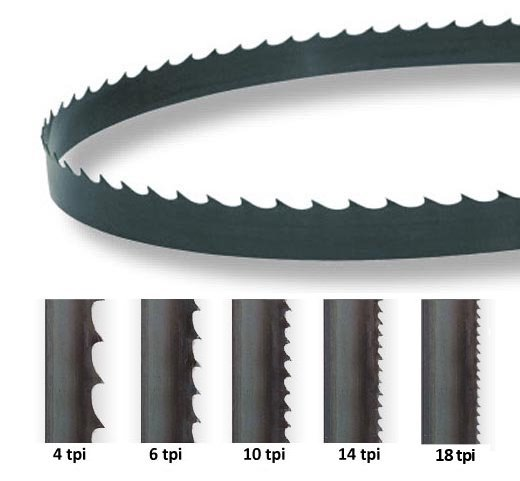

Tooth form & pitch

How to choose the tooth form and pitch of the band saw blade ?This will depend on the type of work you intend to do, i.e. rip cutting (with the grain) or cross cutting (across the grain). Generally, a skip tooth blade is used for rip cutting, whereas a regular or triangular tooth blade is for cross cutting.

The skip tooth is provided on coarse tooth blades, those with 3, 4 and 6 teeth per inch; it has a wide shallow gullet with plenty of space for waste to collect. Please note that the quality of the cut can be adversely affected by sawdust packing between the teeth.

3 tpi (skip form)

Used for deep cutting especially rip cuts. This blade will leave a rough sawn finish although slow feed rate and high tension will improve the finish of the cut.

4 tpi (skip form)

Good for general-purpose use with a degree of cutting across the grain and with the grain. A reasonable finish can be achieved with slower feed rates and good tension.

6 tpi (skip form)

The ideal general purpose blade suitable for cross cutting up to 150mm and ripping in sections up to 50mm thick, although thicker sections can be cut using slow feed.

The regular, or triangular, tooth form is provided on blades with 10 or more teeth per inch where, because of the reduced material removal, there is less need for waste storage.

10 tpi (regular)

Good for cutting plywood and MDF as well as non-ferrous metals and plastics. The finish is good when cutting natural timbers, but the feed rate should be slow and maximum depth of cut should not exceed 50mm. When cutting metals, reduce the speed as much as possible especially when cutting ferrous metals or cast iron.

14, 24 and 32 tpi (regular)

A very clean cutting blade for plywood, plastics and MDF, although too fine for natural timbers unless they are very thin sections (sub 25mm thick). The 14tpi and above blades are very good to use at slow speeds when cutting non-ferrous metals. A slow feed speed should be used at all times with a blade tooth pitch this fine.

Blades with variable pitch teeth (4-6tpi, 6-10tpi and 10-14tpi) are also available for wider ranging applications.