Saw blades for hard and soft materials

• Soft Materials

Non-abrasive soft materials such as cardboard, polystyrene, leather, carpet, and rubber must also be cut accurately. Unlike hard materials such as wood or metal, soft materials require special care when cut to avoid damaging the material. Worthy of mention are the saws below:

• Special Jigsaw blades :

Its sharp knife edge has a material composition of high-carbon steel. This saw can cut irregular or curved shapes due to its thin blade tracked throughout the cutout.

• Band Saw Blades:

Usually made of stainless steel suited for cutting meat. The teeth are beautiful with heat-treated tips.

• Hard Materials:

Woods, metals, stones, porcelain, concrete, asphalt, tiles, etc., can be classified as hard materials. Saw blades for cutting hard substances should be tough enough to withstand their hardness. You need to know these blades have distinctive characteristics. The saw blades that fall under this category are:

• Coping saw:

This is used interchangeably for both metal and wood. Interestingly, its unique feature is its removable blade and ability to cut a profile through a drilled hole. It is effortless to maneuver tight radiuses and curves as well.

• Miter Saw:

Perhaps you have been warned not to cut corners; this saw does precisely that. It is excellent for creating custom angles, especially in molding and trim jobs.

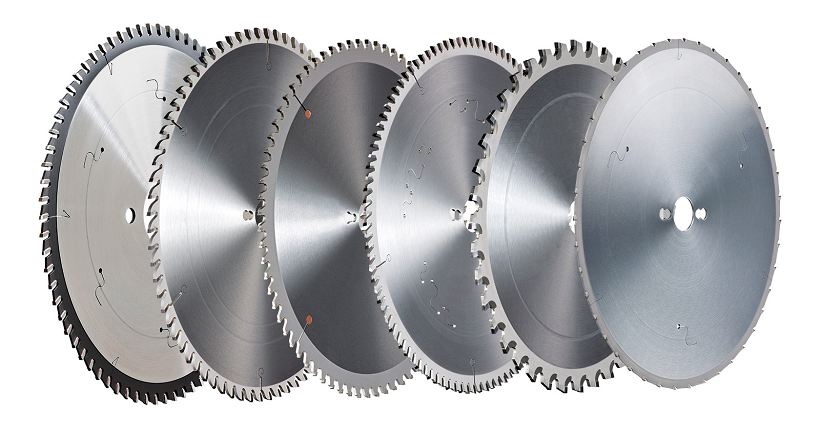

• Circular saw:

This is by far the most common of all saw blades. It comes in two generic types- the worm drive and the sidewinder. The worm drive can produce enough torque to cut through wet lumber and even concrete seamlessly. On the other hand, the sidewinder has its motor attached to its blade but produces less torque.

Other notable saw blades are table, tile, hole, abrasive, and radial-arm edges, which appear similar to the circular saw blade.