Saw blades for cutting acrylic and aluminum alloys are widely used in the construction of modern social civilization. Construction sites, door and window factories, radiator factories, furniture factories, handicraft factories, plate factories, etc. are all essential tools. , many customers will have such a question, is the saw blade universal? Can the saw blade used for cutting acrylic be used to cut aluminum alloy? Can the same saw blade used for cutting aluminum alloy be used to cut acrylic? The answer is no. Yes, it really can't.

Some customers only have one machine, and they think it is troublesome to change the saw blade. To cut aluminum alloy, you need to use a special saw blade for cutting aluminum alloy, and to cut acrylic, you need to use a special saw blade for cutting acrylic. Let me analyze for you why the saw blade for cutting acrylic and the saw blade for cutting aluminum alloy cannot be used in common.

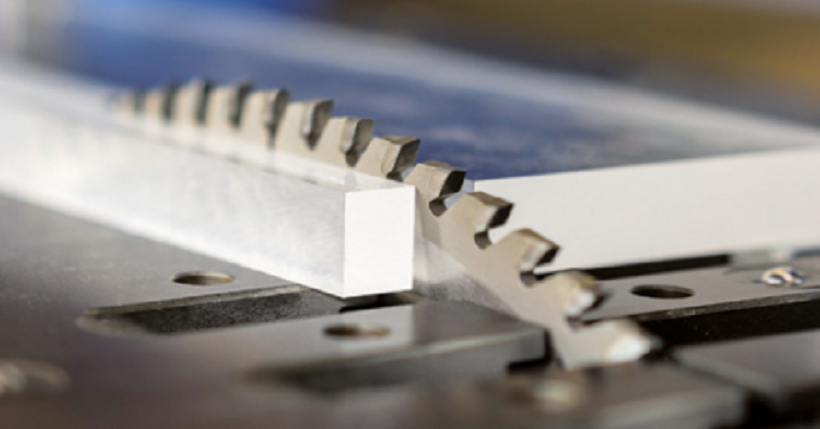

Saw blades for cutting acrylic and aluminum alloys, because acrylic and aluminum alloy materials are different and have different characteristics, so the alloys used for aluminum alloy saw blades and acrylic saw blades are different, that is, the blades are different, acrylic is more brittle, aluminum alloy the strength is high, resulting in different saw blade alloys. Second, the density is different. The tooth shapes of acrylic saw blades and aluminum alloy saw blades are different. Acrylic saw blade used more teeth shape is left-right left-right flat teeth.The saw blade is a ladder flat tooth. Customers who don’t understand it say that it is a large and a small tooth shape. It is also true that if the saw blade of acrylic is used to cut aluminum alloy ,it is easy to break the teeth. Domestic aluminum alloy is cheaper, and domestic saw blade of acrylic is rarely good to use, which is also related to acrylic crisp is not good to cut, easy to burst edge. The requirements for saw blades are extremely high. Generally, acrylic is used for cutting. It is an imported saw blade, which is different when cutting aluminum alloy. There are also many domestic manufacturers. Except for some of which the quality is not up to standard, the cutting effect is also good, and can achieve the effect of no burrs, but it is easier to chip and lose teeth, just like According to some saw blade manufacturers, it is normal for saw blades to lose one or two teeth when cutting aluminum alloy, but imported aluminum alloy saw blades can achieve the effect of no tooth loss or chipping, but the price is higher than that of domestic aluminum alloy saw blades many, and the price is higher than imported acrylic saw blades. Most manufacturers use domestic aluminum alloy saw blades, which can generally be used for one or two months, and imported saw blades can be used for half a year or longer.

The teeth are rarely broken if used badly. It can be repeated after being ground by a professional manufacturer. In summary, saw blades for cutting different materials cannot be mixed, and it is not acceptable to cut through one saw blade for convenience and save money. Therefore, different saw blades should be dedicated to saw blades, and the saw blades for cutting acrylic are for cutting acrylic.