- Super User

- 2025-01-03

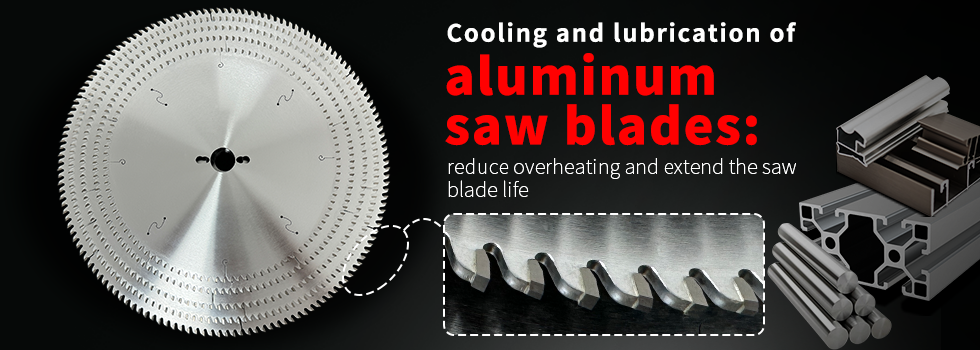

Cooling and lubrication of aluminum saw blades:reduce overheating and extend the

When cutting aluminum alloys,the cooling and lubrication of the aluminum saw blade is crucial, because of high thermal conductivity and low melting point of aluminum alloy are easy to generate too much heat during cutting process,resulting in overheating of the saw blade,melting of the aluminum alloy and adhering to the saw blade, which affects the cutting effect and saw blade life.This article will conduct an in-depth exploration of the importance of cooling and lubrication for aluminum saw blades as well as their related application methods.

1.The importance of cooling and lubrication:

When cutting aluminum,the following issues will affect the processing quality and the service life of the saw blade :

- heat accumulation and overheat: aluminum alloy will rapidly absorb heat during the cutting process,and the high temperature generated by the saw blade during the cutting process is easy to cause damage to the saw blade and even deformation.If the saw blade temperature is too high,then it may also exacerbate the melting of the aluminum alloy, causing it to adhere to the surface of the saw blade, thus affecting the cutting accuracy and efficiency.

- adhesion of aluminum alloys:due to the low melting point of aluminum alloys, the heat generated during the cutting process may cause parts of the aluminum materials to melt and adhere aluminum chips to the saw blade.These aluminum chips attached to the saw blade can cause poor cutting, saw blade clogging of and surface damage.

- wear of saw blade:continuous high temperature and friction will exacerbate the wear of the saw blade, resulting in shortened saw life. Without proper cooling and lubrication, the coating or material on the surface of the saw blade may be rapidly worn, reducing its service life.

Therefore, reasonable cooling and lubrication can effectively reduce overheating, avoid aluminum chip adhesion, reduce friction in the cutting process, thereby extending the service life of the saw blade and improving cutting efficiency and quality.

2.cooling methods

When cutting aluminum alloys,the following are common cooling methods:

2.1 Spray cooling

Spray cooling is to spray the coolant through the nozzle to the cutting area and cool the cutting point directly. Spray cooling can quickly remove the heat generated by cutting, avoiding heat accumulation in the cutting area, thereby reducing the temperature of the saw blade.

- Advantages:it can effectively reduce the temperature of the saw blade,reduce the adhesion of aluminum chips.

- Disadvantages: Spray cooling requires precise nozzle design and coolant control, which can result in poor cooling if the coolant flow is too low.

2.2 Infiltration cooling

Infiltration cooling is the process of partially or completely dipping the saw blade into the coolant during the cutting process, ensuring that the cutting area and the surface of the saw blade are always kept at a low temperature.

- Advantages:The cooling effect is remarkable, which can continuously and steadily reduce the temperature of the saw blade.

- Disadvantages:it has relatively high requirements for equipment, requires a special cooling system,and may cause the waste of coolant.

2.3 gas cooling

Gas cooling generally uses compressed air or cooling gas to reduce the temperature of the saw blade. Especially in some cases where there is no liquid cooling system, gas cooling can be used as a alternative plan.

- Advantages:the requirements for the equipment are relatively low. It is simple and easy to operate, and it will not cause pollution to the cooling liquid.

- Disadvantages: The effect of gas cooling is not as significant as liquid cooling, and a higher gas flow rate may be required to achieve the ideal cooling effect.

3. Lubrication method

3.1 lubricating oil

The use of special cutting lubricating oil can effectively reduce the friction between the aluminum alloy and the saw blade during the cutting process to avoid the aluminum alloy melting and adhering to the saw blade.

- Advantages:the lubricating oil can form a thin film,reduce friction,protect the surface of saw blade and extend the service life.

- Disadvantages:lubricating oil is easy to pollute the working environment and needs to be cleared regularly.

3.2 Water-based lubricant

Water-based lubricant is a mixture of water and lubricant to form a liquid that has the dual role of cooling and lubrication. Water-based lubricants usually contain anti-corrosion components, which can effectively reduce the temperature of the cutting area and improve the cutting effect.

- Advantages:Compared with lubricating oil, water-based lubricants cause less pollution to the environment and have a relatively outstanding cooling effect.

- Disadvantages: The concentration of water-based liquid needs to be correctly configured, otherwise the lubrication effect may be affected.

3.3 solid lubricant

Solid lubricants can provide lubrication in the cutting area, but they are usually applicable to some special cutting environments or used in combination with other cooling methods.

- Advantages:Solid lubricants do not pollute the environment and are suitable for precision machining.

- Disadvantages:The effect of solid lubricants is not as significant as that of liquid lubricants and may require a higher technical investment.

4.The combined use of cooling and lubrication

The cooling and lubrication systems of aluminum saw blades should be reasonably combined and used according to specific processing requirements. Generally speaking, cooling and lubrication can work together in the following ways:

- Cooling and lubrication at the same time: For example, spray cooling can be lubricated at the same time, ensuring that the saw blade is not only cooled but also minimize the friction in the cutting area.

- Intermittent cooling and lubrication: In some cutting processes, intermittent cooling and lubrication methods may be adopted to accommodate changes in different materials or cutting speeds.

5.Conclusion

The cooling and lubrication of aluminum cutting saw blades play an irreplaceable role in improving cutting efficiency, reducing saw blade wear and extending the service life of the saw blades. The reasonable selection and application of suitable cooling methods (such as spray cooling, infiltration cooling or gas cooling) and lubrication methods (such as lubricating oil, water-based lubricant or solid lubricant) can effectively reduce the heat generated during the cutting process and reduce the adhesion problem of the aluminum alloy, thus ensuring that the cutting process is smooth, efficient and precise.In addition, the optimal design of the cooling and lubrication system can not only extend the life of the saw blade, but also improve production efficiency and reduce equipment maintenance costs.Therefore, choosing the right cooling and lubrication method is crucial to improve the quality and efficiency of aluminum cutting.