Introduction Of Diamond Saw Blade knowledge

The diamond on the diamond saw blade is the hardest substance in the world, using diamond to cut all hard materials that are lower than its hardness,such as stone, such as reinforced concrete, such as bricks, such as tiles and some other decorative materials. So what knowledge do diamond saw blades have? Let's find out through the following articles:

1: The best diamond saw blade needs to be stable, sharp and not easy to crack. Stable means that the flatness of the saw blade is high enough, the substrate is not deformed, and the angle of the blade welding is good. The sharpness means that the diamond in the segment is broken just right, and the cutting ability is strong. The fact that it is not easy to crack means that the cutting object is not easy to crack. The main reason is that because the sharpness of the saw blade is too high, the saw blade will not hit the stone, and naturally there will be less cracking.

2: Cutting accuracy is the biggest difference between high-quality saw blades and ordinary saw blades. In the process of continuous rotation of the saw blade, there will be slight deflection, and when the saw blade start to cut the stone, it is easy to have a large deviation in the cutting accuracy, especially for bridge-type multi-blade combination machine, the quality of the saw blade determines the precision of the cutting stone, that is, the flatness of the stone slab. For the infrared bridge cutting machine, the most obvious manifestation of the cutting accuracy of high-quality saw blades is the accuracy of the length and width of the stone, and the difference between good saw blades is less than 0.2mm.

3: Steady feeding speed cutting is a judgment on whether the sharpness of the saw blade is maintained or not. The cutting feed speed is the cutting speed of the saw blade in the forward process when cutting the stone. Stable cutting first means that the cutting speed is stable and will not appear the situation of fast for a while and then slow, the smooth feeding speed indicates that the saw blade maintains a good cutting ability, the speed can be maintained, and the saw blade will not become blunt or fast because of the speed, indicating that the saw blade is in a good cutting condition.

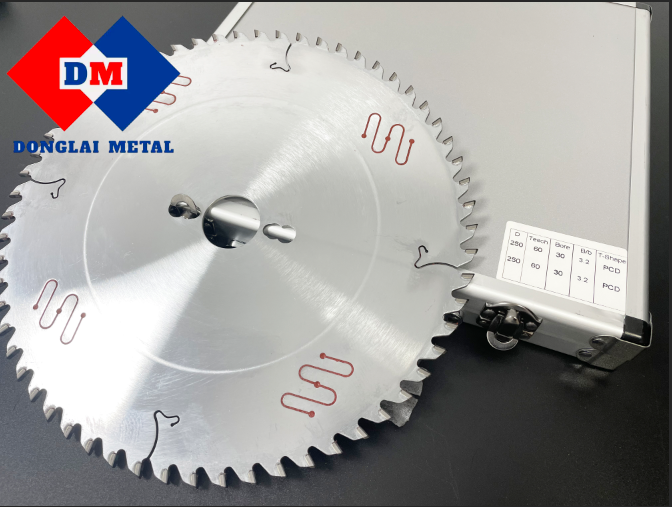

4: Different groove shapes of saw blades represent different cutting capabilities. The main groove type has a key hole shape. The saw blade teeth of this groove type are separated. When cutting, each tooth has an independent cutting ability, which stimulates the potential of the individual teeth, so it has great sharpness and cutting efficiency. improvement. Then there is the wide U-shaped groove. The wide U-shaped groove and the keyhole groove are similar in purpose, but the U-shaped does not completely isolate the connection between the two saw teeth, so the sharpness will be worse, but the performance of cutting continuity have great improvements. Then there is the narrow U-shaped groove. The saw blade of this groove type has strong continuous performance and is usually used for marble cutting with brittle hardness. Finally, there are saw blade grooves with cross slits and hook grooves. This type of saw blade has a strong continuous cutting ability, but it is somewhat insufficient in terms of cutting efficiency.

5: The different serrations of the saw blade represent the difference in cutting performance. There are many types of saw blades. Generally speaking, the common saw blade segments have M type. Most of these saw blades speed up the cutting. Represents the sharpness and efficiency of the saw blade. Other tooth shapes, including V-shaped, W-shaped, T-shaped reinforced type, corrugated type, etc., are all to increase the special cutting ability of the saw blade.

6: There are two elements of the saw blade base that must be paid attention to: low temperature resistance and high temperature resistance, also known as the expansion coefficient.

In general, diamond saw blades still have a lot of knowledge worth knowing. Only by knowing more, we can master the best cutting method in the cutting process, prolong the cutting life of the saw blade, and increase the overall cost-effectiveness of the saw blade.