- Super User

- 2023-04-10

Aluminum alloy saw blade life is short? To keep costs down, these methods of lif

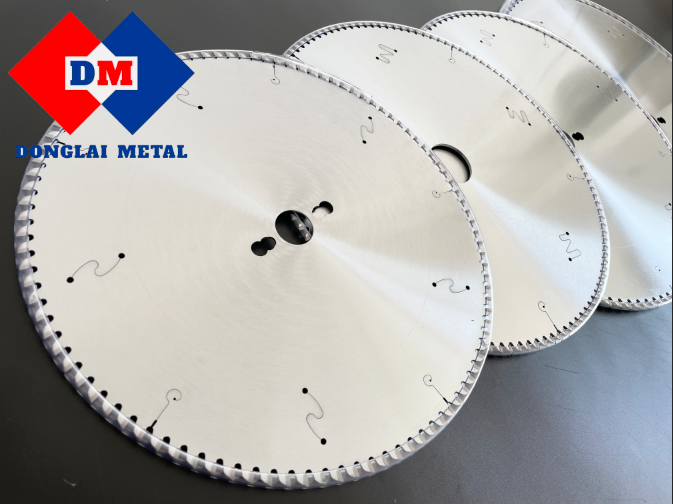

When it comes to aluminum alloy saw blades, people who are engaged in aluminum product processing must be familiar with it, because the quality of a saw blade will directly determine the quality of the products produced by the enterprise. Although the manufacturing and processing technology of saw blades is constantly improving, as a consumable, saw blades have always troubled many enterprises. Why are thin saw blades such a problem for companies? The main reason lies in the quality, price and life of the saw blade. Among them, the price determines the purchase cost of the enterprise, while the quality of the saw blade determines the quality of the product, and the service life is related to the production volume of the enterprise's product per unit time. Because of this, many aluminum product processing enterprises are often very careful when choosing saw blades, and will not make a decision easily without detailed inspection. However, when the saw blade is put into production, the service life of the saw blade often becomes the focus of the enterprise. Because when the quality of the saw blade passes the standard, its life will directly determine the cost performance of an aluminum alloy saw blade. In order to extend the life of the saw blade, we must first start by understanding the factors that affect the life of the saw blade. Generally speaking, the factors that affect the life of the saw blade are as follows.

Factors Affecting the Service Life of Saw Blades

Factor 1: Raw materials used to make saw blades Each raw material has its own properties. Some materials have high thermal conductivity but poor wear resistance, while others are all-around players but expensive. For enterprises engaged in aluminum profile processing, it is particularly important to choose a suitable saw blade according to their own needs. Such as: high-speed steel saw blades, which have particularly strong thermoplasticity and high temperature resistance, and have a long service life, but the price is high. However, the saw blade made of carbon tool steel is limited by its own metal characteristics, and its service life is relatively short compared with saw blades made of other materials. When the saw blade cuts aluminum profiles, it will generate huge friction with the raw material. During this period, the heat generated by the friction is huge. Once the temperature exceeds the tolerance limit of the saw blade, the saw blade will be damaged and its life will be greatly reduced. discount. However, "the magic height is one foot and the road is ten feet higher", in order to improve the service life of the saw blade, saw blade cutting oil was born. Some far-sighted companies even integrate saw blade cutting oil on automatic aluminum cutting machines. Through vertical micro-lubrication system, 0.05 ml of cutting oil is sprayed on the saw blade per second, which not only plays the role of lubrication and cooling, but also greatly prolongs the service life of the saw blade. It has to be admitted that in addition to the above factors, there are many other factors that can affect the life of the saw blade, such as: whether the operation of the employee meets the standard of the process, whether there is any improper use of the saw blade, this series of potential factors will Affect the life of the saw blade. As the saying goes: "Know yourself and know the enemy, and you can win every battle." When we know the factors that affect the service life of saw blades, we can start with the reasons and take targeted measures to prolong the service life of saw blades.

How to prolong the life of the saw blade

Method 1: Choose the right saw blade As a consumable, the saw blade has a life span. Even if it is a saw blade of a major international brand, they cannot guarantee that the saw blade will not be damaged during use. For aluminum profile processing enterprises, it is particularly important to choose a saw blade from the source. It's better to be wise beforehand than to act afterward. Don't want to be dragged down by low-quality saw blades in the production process, it is necessary to purchase saw blades from the source and choose a saw blade with excellent quality and reliable after-sales service.

Method 2: Extend the life of the saw blade by grinding. The scissors at home are blunt. We can prolong its service life by grinding. As for the saw blade, we can also extend the saw blade by grinding the saw blade service life. Yes, you heard it right, saw blades can also be sharpened. When the saw blades of the enterprise are worn out due to long-term use and the saw teeth become dull, we can use a special saw blade grinding machine to grind the saw blades. Generally speaking, the service life of a saw blade is generally about 1 to 3 months under the condition of extreme use, but when the enterprise chooses to grind the saw blade, the service life of the saw blade can be extended by at least one month. For aluminum profile processing enterprises, on the one hand, it reduces the cost of purchasing saw blades, and on the other hand, it buys enough time for purchasing new saw blades. To a certain extent, it effectively ensures the continuity of the production process of the enterprise. . Although the thin saw blade is inconspicuous, if you pay enough attention, you can take certain measures to effectively extend the life of the saw blade. For enterprises, it can kill two birds with one stone.