Macheka a diamondi ndi amodzi mwa masamba omwe amagwiritsidwa ntchito kwambiri. Chochititsa chidwi kwambiri ndi tsamba la machekalo ndikuti zoyika zina zimayikidwa pa tsamba la macheka kudzera munjira zosiyanasiyana pambuyo pake. Chitsamba ichi chimagwiritsidwa ntchito kwambiri m'mafakitale odula miyala ndi konkriti. Nkhaniyi ikuwonetsa machitidwe osiyanasiyana amitundu yosiyanasiyana ya diamondi yoyika ma saw pofotokoza za mawonekedwe a macheka a diamondi.

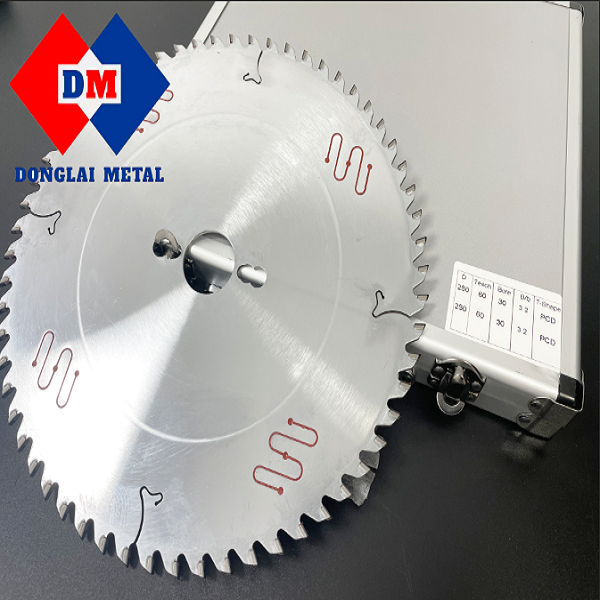

1: Zithunzi za PCD za diamondi.

Tsamba lamtundu uwu limagwiritsidwa ntchito makamaka podula matabwa, komanso lingagwiritsidwe ntchito pokonza miyala. Chinthu chachikulu cha mtundu uwu wa macheka ndi chakuti choyikapo ndi chofanana ndi cha TCT, koma kusiyana ndi gawo loyikapo la macheka. Zoyikapo zimapangidwa ndi aloyi yolimba, ndipo njira yomwe imagwiritsidwa ntchito ndi tsamba la macheka a PCD ndikuti mapepala ena a PCD amafunikira kuwotcherera pamasamba. Panthawi imodzimodziyo, moyo wautumiki wa choyikapo ukhoza kukonzedwanso. Miyala nthawi zambiri imasinthidwa ndi PCD. Chifukwa choyamba ndi chakuti mtengo wa PCD mapepala gulu ndi mkulu, ndi vuto diamondi kukhudzana, kotero kudula dzuwa adzakhala otsika.

2: Tsamba la macheka a diamondi wozizira.

Mtundu uwu wa macheka tsamba amakonzedwa ndi ozizira kukanikiza ndi sintering. Chifukwa cha zovuta zaukadaulo, thupi la tsamba ndi gawo lamutu la tsamba la macheka zimalumikizidwa pamodzi. Popeza palibe malo ambiri olumikizirana pakati pa awiriwo, ndipo pali kusowa kwa zida zoyenera zolumikizirana pakati pa ziwirizi, panthawi yokonza, ngati mphamvu yokonzayo ndi yayikulu kwambiri, ndizosavuta kuti mano a tsamba la macheka awuluke. Pachifukwa ichi, masamba a macheka a oyikapo ozizira nthawi zambiri amagwiritsidwa ntchito pamasamba okhala ndi mainchesi osakwana 230mm. Pokonza miyala, mtundu uwu wa macheka umagwiritsidwa ntchito kwambiri pazida zamanja, monga zopukutira pamanja, makina odulira m'manja ndi makina ena. Palinso makasitomala ena aku Vietnam omwe amagwiritsa ntchito macheka a 230mm podula miyala yamwala yodziwika bwino. Kuphatikiza pa zovuta zapang'onopang'ono komanso kutsika kocheperako kwa tsamba, mtengo wagawo ndi wotsika mtengo, ndipo zabwino zambiri monga kusakhala ndi kuwotcherera kumapangitsanso mtundu uwu wa macheka pakupanga miyala kuti igwiritsidwe ntchito bwino.

3: High pafupipafupi kuwotcherera diamondi amaika macheka tsamba.

Mtundu woterewu wa macheka amawotcherera kuti alowetse gawo la diamondi pamtunda wa tsamba la macheka, ndipo gawo la diamondi nthawi zambiri limapangidwa ndi kukanikiza ndi kutentha. Pogwiritsa ntchito ma solder othamanga kwambiri, solder nthawi zambiri amawonjezedwa kumutu wodula ndi ma saw blade base, omwe nthawi zambiri amakhala ma copper solder pads, silver solder pads, kapena flux ina. Tsamba la macheka limeneli lili ndi makhalidwe otsatirawa: Choyamba, limatha kuwotcherera pa tsamba lalikulu la macheka lopanda kanthu, lomwe lingatsimikizire kuti tsamba lalikulu la macheka lingagwiritsidwenso ntchito podula mwala, ndipo limatha kudula midadada yokulirapo. Chachiwiri, gawo la diamondi likhoza kusinthidwa mwamsanga, lomwe lingathe kuthetsa mwamsanga vuto la kuvala kwa gawo la diamondi. Magawo a diamondi akasinthidwa, tsamba la macheka litha kugwiritsidwanso ntchito, zomwe zimapulumutsa mtengo wokwera wa macheka. Chachitatu, mphamvu zowotcherera pafupipafupi ndizokwera kwambiri. Ngati wololera tabu ndi solder ntchito kuwotcherera, mphamvu kuwotcherera gawo diamondi ndi mkulu kwambiri. Kupanda kutentha kwapamwamba, kukana kwamphamvu ndi kupindika kwa kuyika uku kulipo ndipo kuli koyenera kudula miyala yonse. Chachinayi, panopa kuwotcherera makina mtengo ndi otsika, ndipo n'zosavuta kuchita kuwotcherera processing, ndipo fakitale akhoza kuzindikira zikhalidwe za processing paokha kuwotcherera pamtengo wotsika.

4: Laser diamondi amaika macheka tsamba.

Tsamba lamtundu uwu limatenthetsa mbali zina za macheka opanda kanthu ndi magawo a diamondi pogwiritsa ntchito laser, ndipo madera awiriwa amadutsa kutentha kwambiri kuti apange zida zatsopano za alloy. Mphamvu ya aloyiyi ndi yokwera kwambiri kuposa yazitsulo zowotcherera,ngakhale kangapo kumtunda, kotero mwayi waukulu wa pepala laser ndi kuti kuwotcherera mphamvu ndi mkulu, ndipo akhoza kudula zipangizo zolimba. Mwachitsanzo, konkire yolimbikitsidwa, kudula thupi lachitsulo, ndi zina zotero, zikhoza kudulidwa ndi njira iyi yodula. Pankhani ya kugwiritsa ntchito mwala, chifukwa chakuti pepala la laser likuwotcherera, limapangitsa kuti pakhale kusintha pang'ono kwa thupi la pepala, ndipo zimakhala zovuta kuzigwiritsa ntchito pambuyo pake disassembly ya gawo la diamondi. Choncho, m'makampani opanga miyala, opanga ochepa amagwiritsa ntchito njirayi. Pokhapokha ngati pali zofunikira zodulira zapadera, monga kudula kowuma, monga kuuma kwakukulu kwa mwala, ndi zina zotero, muzochitika zapaderazi, pepala la kuwotcherera la laser lingagwiritsidwe ntchito podula mwala.

5: Mabala a diamondi a Brazing ndi electroplating.

Masamba akale a diamondi adawonetsedwa ndikuyika ma diamondi pagawo la tsamba la macheka, ndipo njirayi imatha kugwiritsidwabe ntchito pofotokozera. Daimondi imayikidwa pamwamba pa tsamba la macheka ndi electroplating ndi vacuum brazing, ndipo kudula kumatsirizidwa ndi kudula mwala ndi diamondi pamwamba pa tsamba la macheka. Tsamba lamtundu uwu limagwiritsidwa ntchito kwambiri podula mwala wouma, makamaka podula bwino. Mtundu uwu wa macheka tsamba akhoza kwambiri patsogolo kudula Mwachangu ndipo sakhudzidwa ndi chilengedwe chakunja.

Pomaliza, tsamba la macheka a diamondi ndilofunika kwambiri pakudula miyala. Titha kunena kuti zoyikapo miyala zimatha kukwaniritsa pafupifupi zosowa zonse zamwala, ndipo magwiridwe antchito a macheka awa adzakhalanso ndi kuthekera kwakukulu kwachitukuko m'tsogolomu.