Donglai Metal provide high performance saw blades, offer cost-saving solutions in your different cutting industry!

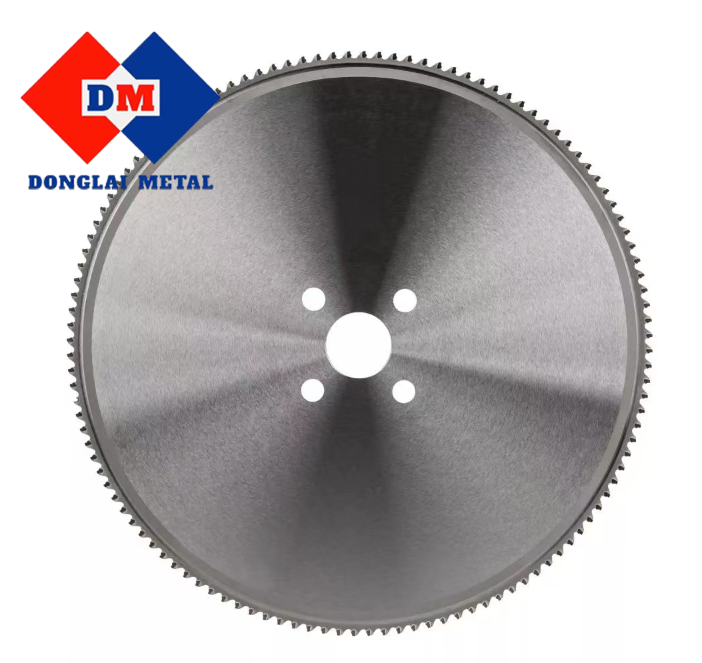

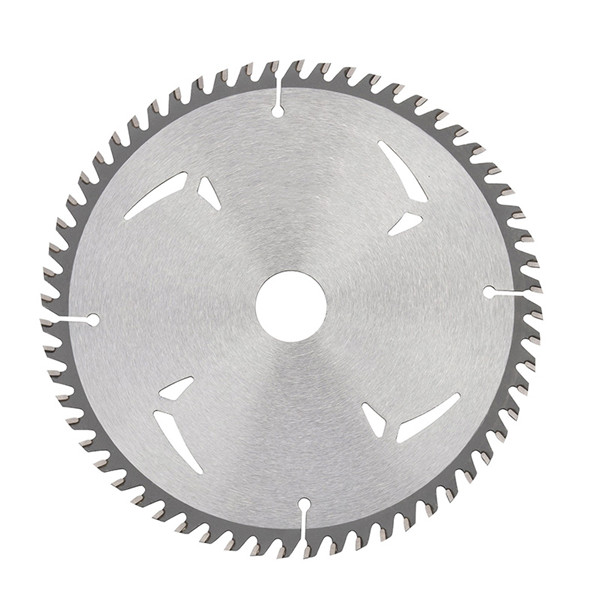

Cold Saw Blades are designed to cut ferrous and non-ferrous metals. Cold Saw blades are made from M2 HSS steel and M-35 (5% cobalt) for stainless and tool steels. Our cold saw blades are heat treated to 64-65 HRc and triple tempered and press quenched to ensure flatness. These blades are specifically suited for use on manual, semi-automatic and fully-automatic cold saws. Cold saw blades operate at slow speeds typically 10-50 RPM when cutting ferrous metal but can run faster when cutting non ferrous metal. Flood coolant or at the least a mist spray is highly recommended for optimal cut quality and blade life. When ordering please specify the type of material being cut so the correct tooth geometry is furnished for your job.

Cold Saw Blades are available with PVD coatings as well PVD coatings increase the surface hardness and allow for increased speeds and feeds. The proper PVD coating is determined by the material being cut, the saw being used and the method of coolant application eg. flood, mist or no coolant.

Application:

Cold saw blades are commonly used to cut tube, pipe, solid bar, angle iron, casting, forgings, structural shapes, billets etc.

Advantage:

The sawing speed is fast, the cutting efficiency is optimized, and the work efficiency is high; the saw blade deflection is low, the section of the steel pipe to be sawed has no burrs, the sawing accuracy of the workpiece is improved, and the service life of the saw blade is maximized.

Specification:

The outer diameter of the saw blade: 50-650 mm; the hardness of the saw blade is HRC 65;

Note: Can be customized according to customer's requirements.

FACTORY TOUR

Hunan Donglai Metal Technology Co., Ltd.

ADDRESS:Building 1 Taishan Road, Tianyuan District Zhuzhou Hunan China

Phone:+86 187 0733 6882,+86 152 7339 2257

Email:info@donglaimetal.com