ⅰ.performance پہلو:

1. سختي ۽ لباس جي مزاحمت:

مرتيل سرد ڏٺو ويو آهي: اهو عام طور تي سخت سختي ۽ بهتر لباس جي مزاحت هوندي آهي.

اڻ کٽندڙ ٿڌي ڏٺي: نسبتا ڳالهائڻ، سختي ۽ لباس جي مزاحمت گهٽ آهي، ان کان پوء ڊگهي مدي واري استعمال کي آسان ۽ خراب ڪرڻ آسان آهي.

2. ڪارڪردگي جي ڪارڪردگي:

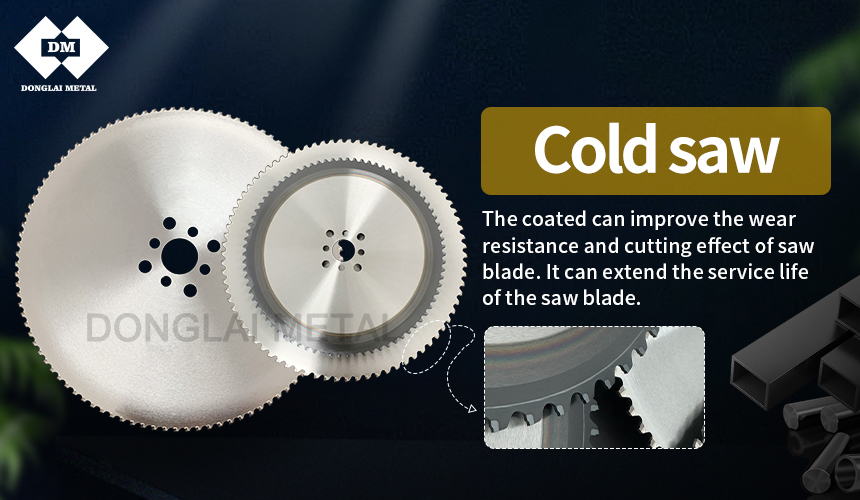

ڪوٽ ڪيل سرد ڏٺو ويو: ڪوٽا ڏٺو ته ڏٺو ويو بليڊ جي ڪٽڻ جي ڪارڪردگي کي بهتر بڻائي سگهي ٿو ۽ ڪٽڻ کي ڪٽڻ.

اڻ کٽندڙ سرد: ڪٽڻ واري ڪارڪردگي نسبتا غريب آهي، شايد وڌيڪ گرمي پد جي ضرورت ٿي سگهي ٿي، وڌيڪ گرمي پد جي معيار ۾ گهٽتائي جي ڪري.

3. ڪارروائي جي مزاحمت:

ڪوٽا سرد ڏٺو: سٺو سنکنرن جي مزاحمت.

غير متوقع ٿڌي ڏاڪڻ: غريب يا نااهل يا ياکاڻي ماحول ۾ پختو ڪرڻ آسان آهي، پراڻل بليڊ جي ڪارڪردگي کي متاثر ڪرڻ آسان آهي.

ⅱ.erservice زندگي جو رستو:

1.Durability:

مرشر لڳي: ان کان وڌيڪ انهي سڪون آهي، اهو اڪثر ڪري عام آهي، ۽ انهي جون حرڪتون استعمال جي ساڳين حالتن کان وڌيڪ آهن.

اڻ وڻندڙ سرد: خدمت زندگي کي نسبتا طور تي عام طور تي نن adds ڙو نن class ڙو نن class ڙو آهي، جيڪو پيداوار جي قيمت ۽ بحالي جي قيمت کي وڌائي ٿو.

2. مشنن جي قيمت:

ڪوٽا سردي ڏٺو: ابتدائي قيمت وڌيڪ ٿي سگهي ٿي، پر ان جي ڊگهي سروس جي زندگي ۽ گهٽ سار سنڀال جي گهرج جي ڪري گهٽ آهي.

اڻ کٽ ٿڌو ڏٺو: ڏٺو ويو بليڊ کي بار بار مٽائڻ جي ضرورت آهي، ۽ سار سنڀال جي قيمت لڏپلاڻ کان وڌيڪ آهي.

ⅲ. پرنٽ پہلو:

1. پاليس جي قيمت:

ڪوٽا سرد ڏٺو ويو آهي: اهو عام طور تي وڌيڪ مهانگو آهي ڇاڪاڻ ته ان جي پيداوار جو عمل پيچيده آهي ۽ خاص منڊي مواد ۽ ٽيڪنالاجي جي استعمال جي ضرورت آهي.

اڻ کٽ ٿڌو ڏٺو: قيمت نسبتا گهٽ، قيمتي حساس استعمال ڪندڙن لاء مناسب آهي.

2. ڪارڪردگي ڪارڪردگي:

ڪيليڊ سردي ڏٺو آهي قيمت....

اڻ ڏٺي سردي: قيمت سستو آهي، پر ان جي مختصر خدمت جي زندگي جي ڪري، انهي جي وڌيڪ متبادل ۽ سار سنڀال جي ڪري شايد وڌيڪ گهٽ آهي.