Dhaimondi rekuisa saha blade ndeimwe yeanonyanya kushandiswa masaha blade. Chinhu chikuru cheiyi saha blade ndechekuti mamwe anoiswa anoiswa pashizha resaha kuburikidza neakasiyana maitiro mune inotevera nhanho. Iyi saha blade inoshandiswa zvakanyanya mumaindasitiri ekucheka kwematombo uye kongiri. Ichi chinyorwa chinosuma maitiro akasiyana eakasiyana madhaimondi ekuisa saw blades nekuunza iwo chaiwo maitiro edhaimondi rekuisa saw blades.

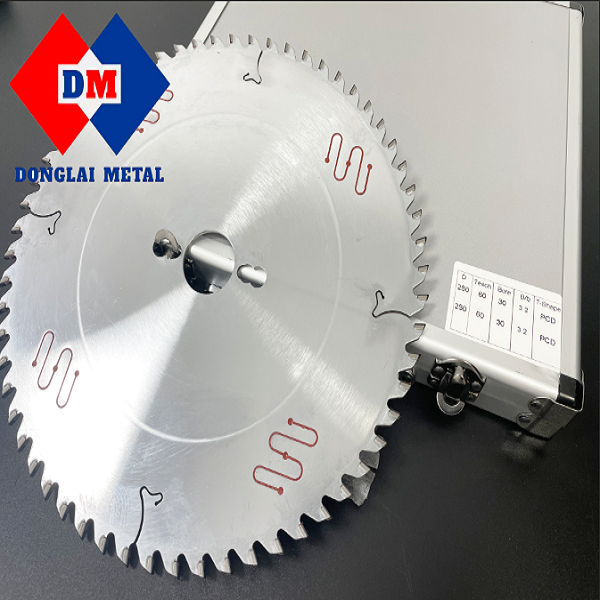

1: PCD diamond kuisa saw blades.

Rudzi urwu rwemasaha runonyanya kushandiswa pakucheka huni, uye rinogonawo kushandiswa kugadzira matombo. Chinhu chikuru cherudzi urwu rwesaha blade ndechekuti kupinza kwakafanana neyeTCT, asi mutsauko ndiyo chikamu chekuisa chesaha blade. Izvo zvinoiswa zvinogadzirwa neakaoma alloy, uye maitiro anoshandiswa nePCD insert saw blade ndeyekuti mamwe maPCD anoumbwa mapepa anoda kusungirirwa pabadza resaha. Panguva imwecheteyo, hupenyu hwebasa hwekuisa hunogonawo kuvandudzwa. Matombo haawanzogadziriswa nePCD. Chikonzero chekutanga ndechekuti mutengo wePCD composite sheets wakakwira, uye dambudziko rekufumura madhaimondi, saka kugona kwekucheka kuchave kwakaderera.

2: Inotonhora-yakatsikirirwa diamond inopinza saw blade.

Rudzi urwu rwesaha blade inogadziriswa nechando kudzvanya uye sintering. Nekuda kwezvinetso zvetekinoroji, iyo blade muviri uye chikamu chemusoro chesaha blade zvinonyatso sintered pamwechete. Sezvo pasina nzvimbo dzakawanda dzekubatanidza pakati pezviviri, uye pane kushayikwa kwezvinhu zvakakodzera zvekubatanidza pakati pezviviri, panguva yekugadzirisa, kana simba rekugadzirisa rakanyanyisa, zviri nyore kuti mazino emucheka wesaha abhururuke kunze. Nechikonzero ichi, masaha ekuisa inotonhora-akadzvanywa anonyanya kushandiswa mumasaha ane dhayamita isingasviki 230mm. Mukugadzirisa kwematombo, rudzi urwu rwesaha runonyanya kushandiswa mumidziyo yemaoko, yakadai semakona anobatwa nemaoko, michina yekucheka inobatwa nemaoko nemimwe michina. Kune zvakare vamwe vatengi veVietnamese vanoshandisa 230mm saw blades yekucheka matombo matombo ane zvakatemwa. Pamusoro pezvinetso zvekunonoka kushanda zvakanaka uye mwero wakaderera wekushandisa kweblade, mutengo weyuniti wakachipa, uye zvakanakira zvakawanda senge pasina welding zvinoitawo kuti rudzi urwu rwesaha blade mukucheka kwematombo kushandiswa kwakanaka mukuita.

3: High frequency welding diamond inoisa saw blade.

Rudzi urwu rwesaha blade inosungirirwa kuisa chikamu chedhaimondi pachigadziko chesaha, uye chikamu chedhaimani chinowanzo gadzirwa nekupisa nekutsikirira. Kuburikidza nehigh-frequency soldering, solder inowanzowedzerwa kune cutter head uye saw blade base, inowanzova copper solder pads, silver solder pads, kana imwewo flux. Iri saha blade rine hunhu hunotevera: Chekutanga, rinogona kusungirirwa pabango hombe resaha risina chinhu, rinogona kuona kuti saizi hombe yesaha inogona kushandiswawo kucheka dombo, uye inogona kucheka matombo makuru. Chechipiri, chikamu chedhaimondi chinogona kuchinjwa nokukurumidza, chinogona kukurumidza kugadzirisa dambudziko rekupfeka kwedhaimondi. Kana seti yezvikamu zvedhaimondi zvatsiviwa, blade yesaha inogona kushandiswa zvakare, izvo zvinochengetedza mutengo unodhura wekutsiva weiyo saha blade base. Chechitatu, iyo yakakwirira frequency welding simba yakakwira. Kana iyo inonzwisisika solder tebhu uye solder yakashandiswa kugadzira, iyo welding simba rechikamu chedhaimani chakakwira zvakanyanya. Mukusavapo kwemamiriro ekushisa kwepamusoro, kupikisa kwemaitiro uye kupeta kupikisa kweiyi kuiswa kunowanikwa uye kwakakodzera kune ese matombo ekucheka. Chechina, ikozvino welding muchina mutengo wakaderera, uye zviri nyore kuita welding processing, uye fekitori inogona kuona mamiriro ekuzvimiririra welding processing nemutengo wakaderera.

4: Laser diamond inoisa saw blade.

Iri rudzi rwesaha rinopisa zvikamu zvesaha base base isina chinhu uye zvikamu zvedhaimondi nenzira yelaser, uye nzvimbo mbiri idzi dzinopfuura nekupisa kwakanyanya kugadzira zvinhu zvitsva zvealloy. Kusimba kweiyi alloy material yakakwira zvakanyanya kupfuura iyo yewelding material,kunyangwe zvakati wandei kukwira, saka mukana mukuru weiyi laser sheet nderekuti kusimba kwewelding kwakakwira, uye inogona kucheka zvimwe zvinhu zvakaomarara. Semuenzaniso, kongiri yakasimbiswa, simbi yesimbi yekucheka muviri, nezvimwewo, inogona kutemwa nenzira iyi yekucheka. Panyaya yekushandiswa kwedombo, nekuda kwekuti pepa relaser riri mukuita welding, rinokonzeresa kushomeka kudiki kumuviri weshizha, uye zvinonetsa kubata mune inotevera disassembly maitiro echikamu chedhaimani. Nokudaro, mumhizha yekugadzira matombo, vashoma vanogadzira vanoshandisa nzira iyi. Kunze kwekunge paine zvakakosha zvekucheka zvinodiwa, sekucheka kwakaoma, senge kuomarara kwedombo, nezvimwewo, mune izvi zviitiko zvakakosha, laser welding sheet inogona kushandiswa kucheka ibwe.

5: Brazing uye electroplating diamond saw blades.

Iwo ekutanga madhaimondi akaona mablades akaunzwa nekuisa madhaimondi pasaha blade substrate, uye iyi nzira inogona kushandiswa sereferensi. Iyo dhaimondi inogadziriswa pamusoro peiyo blade yesaha ne electroplating uye vacuum brazing, uye nzira yekucheka inopedzwa nekucheka ibwe nedhaimondi pamusoro peiyo blade yesaha. Rudzi urwu rwemasaha runonyanya kushandiswa pakucheka matombo akaoma, kunyanya pakucheka hunyanzvi. Rudzi urwu rwesaha blade rinogona kuvandudza zvakanyanya kuchekwa kwekucheka uye harina kukanganiswa nemamiriro ekunze.

Mukupedzisa, dhaimondi rekuisa saw blade rine kukosha kukuru pakucheka matombo. Zvinogona kutaurwa kuti kuiswa kwematombo kunogona kuzadzisa zvinenge zvese zvekuchekwa kwematombo, uye kuita kwemasaha aya kuchavawo nebudiriro huru mune ramangwana.