Usati wasarudza iro dhaimani rakakodzera rekushandisa kwako, zvinobatsira kuziva kuti anogadzirwa sei uye anoshanda sei.

Kuve neruzivo urwu kunovimbisa chiitiko chakabudirira panzvimbo yako yebasa.

Mashizha edhaimani anogadzirwa sei?

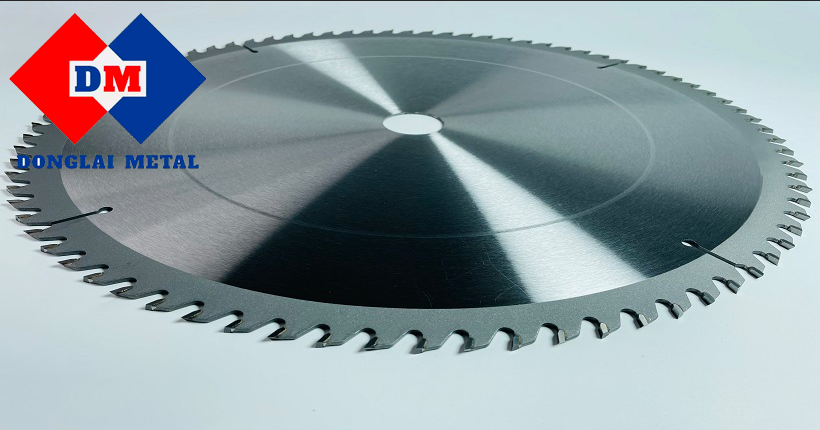

Mabladhi edhaimani anogadzirwa nezvikamu zviviri: simbi yepakati uye chikamu.

1. Steel Core: Rutsigiro Chikamu

Iyo yepakati inowanzoita yakatenderedzwa flat simbi disc inoshandiswa kutsigira ekunze zvikamu. Dhaimondi rinogona kusungirirwa kupakati uchishandisa vacuum brazing, sintering, kana laser welding.

Vacuum Brazed kana Sintered Attachment

Iyo process level inoshandiswa kugadzira musimboti inoenderana nemaitiro ekunamatira. Mutengo wakaderera, vhoriyamu yakakwira mablades anoshandisa vacuum brazed kana sintered attachment process. Vacuum brazed uye sintered blades inoitirwa yakaoma yekucheka zvinhu zvakapfava pane yakaderera bhiza midziyo. Iwo macores anoshandiswa kune aya mablades anowanzo kuve akapusa uye haaite akawanda ematanho emablades kune mamwe maapplication ane hukasha.

Laser Welded Attachment

Pakati pemhando nhatu dzakajairika dzekubatanidza zvikamu kumusimboti, uye nekure nzira inoburitsa chisungo chakasimba kune yakakosha, laser welding. Saiye piyona mulaser welding, Norton inoramba ichigadzira uye yakakwana laser welding matekiniki. Izvo zvakanyanya hutsinye zvikumbiro zvemadhaimani blades zvinosanganisira kushandiswa kwepamusoro bhiza midziyo yakanyorova yekucheka zvinhu zvakaoma kusvika pakadzika kucheka kwakadzika. Simbi macores ezvishandiso zvehasha izvi zvakakora, zvinopisa-kugadziriswa, kunyatsoita-pasi, uye kumanikidzwa. Iyo yekuwedzera ukobvu uye kupisa kurapwa inobvumira iyo yakakosha kutsungirira kuchinjika kushushikana kweiyo inorema midziyo uye yakakwirira bhiza simba. Kugaya chaiko pamusoro pepamusoro kunoderedza kukweva ukuwo tensioning ichisimbisa kupfakanyika kweblade pane imwe rpm renji.

2. Chikamu: Kucheka Chikamu

Iyo Segment inoumbwa nezvikamu zviviri: diamond uye simbi zvisungo.

a. Makristasi edhaimani (Cheka)

Dhaimondi rinoshandiswa rinogadzirwa kana kugadzirwa zvakasiyana nemasikirwo. Dhaimondi rakagadzirwa rinofarirwa kupfuura dhaimani rechisikigo nekuti hunhu hwakakosha senge crystal chimiro, saizi, uye simba zvinogona kudzorwa zvakanyanya kuburikidza nekugadzira maitiro. Iko kugona kudzora hunhu hwakakosha hweiyo synthetic diamond inobvumira kufanotaura kwakaringana kwekumhanya kwekucheka uye hupenyu hweblade pamwe nekuenderana kudzokororwa. Zvimwe zvinhu zvakakosha zvekufunga nezve diamond ndezvi:

• huwandu hwedhaimani muchikamu

• kunaka kwedhaimani muchikamu

• saizi yedhaimani muchikamu

Kuwanda kweDaimondi:

Huwandu hwedhaimondi muchikamu hunochinja uye hunoda simba rakawanda rebhiza sezvo zviri mudhaimondi zvichiwedzerwa muchikamu. Zvichingoreva zvinoreva kuti sezvo dhaimani rakawedzerwa pachikamu chinodiwa simba rebhiza kuita kuti blade ichekwe. Mukutaura kwekuita izvi zvinoreva kuti mablades emasaha akakwira bhiza achave nedhaimani rakawanda muchikamu.

Hunhu hweDaimondi:

Hunhu hwedhaimani hunotaridza kugona kwedhaimondi rega rega kurwisa kupisa uye kuchengetedza nzvimbo yakapinza. Madhaimani ari nani anogona kubata poindi yakareba patembiricha yepamusoro.

Kukura kweDaimondi:

Pakupedzisira chinhu chekupedzisira kufunga ukuru hwedhaimani. Saizi yedhaimondi yemunhu inotsanangurwa mune mesh siyana se25-35 kana 50-60. Kukwira kwenhamba ndiko kukwenenzvera kwezvikamu zvega. Mukushandisa dhaimani rakapfava rinoshandiswa kune zvakaomarara-zvakaoma seChert kana Quartz nepo hombe yakakasharara yedhaimani inoshandiswa kune zvinyoro seasphalt uye zvidhinha zvitsvuku zvevhu zvakapfava.

b. Bonding System (Wears)

Chisungo musanganiswa wesimbi hupfu hunoshandiswa mumisanganiswa yakasiyana siyana kuti uwane mapfekero chaiwo. Bond yakanyatsogadzirwa inobata iyodhaimondi riri panzvimbo, rinongoreba zvakakwana kuti uwane kushandiswa kwakanyanya kubva pamadhaimondi risati raburitsa dombo uye nekufumura rinotevera dhaimondi.

Muyero wekupfeka wechikamu unogona kurerutswa kusvika pakukwanisa kwesimbi kuramba kupfeka kubva kubrasion. Simbi dzine low abrasion resistance sebronze dzinonzi dzakapfava. Iwo mabhondi akapfava anowanzo kugadzirwa nesimbi dzakapfava seBronze uye akajairika pakucheka zvakanyanya kuomarara zvisingaite senge porcelain. Iwo akaomeswa zvisungo anonyanya kugadzirwa nesimbi dzakaoma seTungsten Carbide uye zvinowanzoitika kana uchicheka zvakapfava zvinhu zvinokurisa seasphalt kana kongiri ichangobva kudururwa.

Nzira yakanakisa yekurangarira bond-to-material application ndeye "anopikisa anokwezva" - mabhondi akaomarara ezvinyoro zvinokweshera nepo mabhondi akapfava achishandiswa kune zvakaoma zvisinganyanye kubhura. Mune zvimwe zviitiko zvakanyanya, zvinokwanisika kungotonga kuoma kweblade nekucherechedza ruvara rwechikamu. Nekuda kwekuti mashizha akapfava ane ruzhinji rweBronze, mashizha akapfava emidziyo yakaoma kwazvo achave neyero tint kuchikamu.