Tsebo ea ts'ebeliso le tlhokomelo ea mapolanka a li-multi-blade saw

Tsebo ea ts'ebeliso le tlhokomelo ea mapolanka a li-multi-blade saw

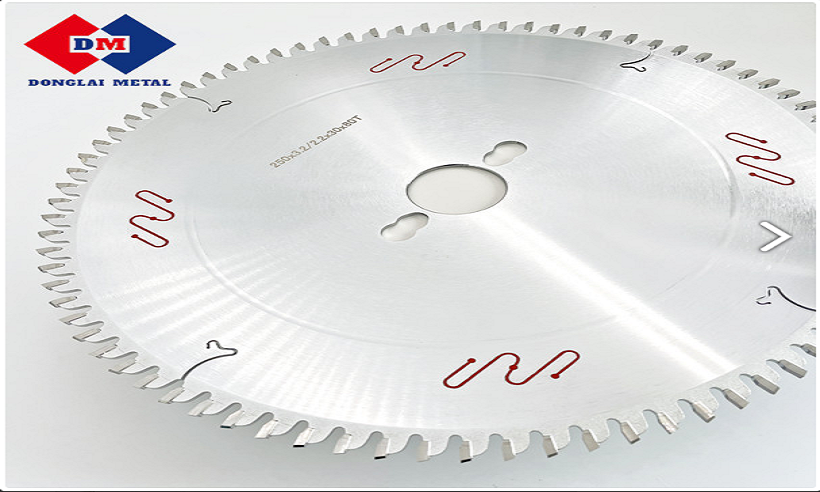

* Mokhoa oa ho sebelisa: Lehare la sakha la multi-blade ke lehare la sakha le kentsoeng le ho sebelisoa hammoho ka lihlopha. Hangata e sebelisoa bakeng sa ho itšeha ka longitudinal ea lehong le tiileng, bakeng sa ho etsa li-square le lihlopha. Mofuta oa leino ka kakaretso ke BC kapa P, 'me tsela ea sakha e ka har'a 1.6-3.2mm, e ka ntlafatsang haholo katleho ea mosebetsi oa basebetsi le ho ntlafatsa katleho ea tlhahiso.

* Ts'ebetso e thusang

1.Outer scraper - ka kakaretso e sebelisetsoa ho rema lehong le metsi, le leng molemo ho tlosa chip, ho fokotsa haholo ho khomarela lisebelisoa tsa lehong.

2.Inner scraper - ka kakaretso e sebelisetsoa ho rema lehong le thata, le thusang ho fokotsa li-burrs sebakeng sa ho itšeha, Boloka qetello e boreleli.

3. keyway - tlohella lehare la sakha hore le lokisoe hamolemo holim'a seluloana 'me le tsamaee hantle, thibela lehare la sakha hore le se ke la thella, 'me le tlamelle lehare la sakha.

*Mabaka a ho chesa likhaba tsa sakha

1.Li-saw blades ha li bohale

2.Too many blade teeth kapa many too many blade installations

3.Saw blade mocheso dissipation ha e ntle

4.Thepa ha e lumellane le mefuta e mengata ea ho sebetsa ea mochine

5.Lebelo la mochine ha le lumellane le lebelo la ho fepa;

*Tharollo

1. Haeba lehare la saw ha le bohale, ho hlokahala hore u sila lehare la saw ka nako

2. Khetha lehare la sakha le nang le meno a fokolang kapa fokotsa palo ea likotoana tse kentsoeng

3. Ho molemo ho reka lehare la sakha le nang le masoba a pholileng, kapa o ka eketsa metsi (a mang a pholileng) ho fokotsa mocheso.

4. Lokisa mochine hantle kapa u khethe tlhaloso le boholo ba thepa ea ho sebetsa

5. Lokisa ka nepo lebelo la ho fepa ho latela thepa