- Super User

- 2023-04-19

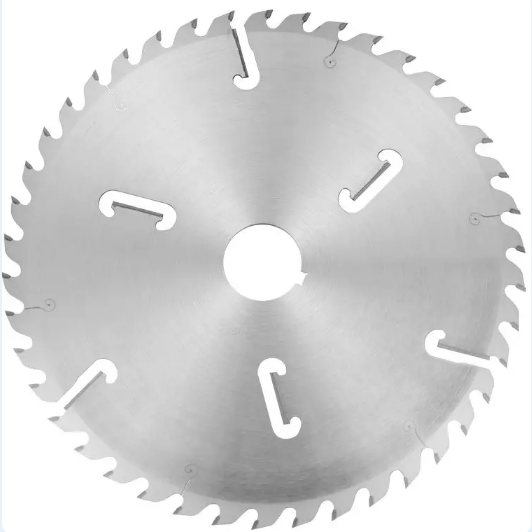

Botenya ba boleng ba lehare la li-multi-blade bo phetha karolo ea bohlokoa polei

Botenya ba lehare la saw blade Ka khopolo, re tšepa hore lehare le lesesaane la sakha le molemo. Ha e le hantle, kerf ea saw ke mofuta oa tšebeliso. Thepa ea alloy saw blade base le ts'ebetso ea ho etsa lehare la sakha li khetholla botenya ba lehare la sakha. Haeba botenya bo le bobebe haholo , li-blade saw blades li bonolo ho sisinyeha ha li sebetsa, tse amang phello ea ho itšeha. Ho nka mohlala oa lehare la sakha ea mefuta e mengata e le mohlala, botenya ba bophara ba 110-150MM ka ntle bo ka ba 1.2-1.4MM, 'me botenya ba 205-230MM bophara ba lehare la saw ke hoo e ka bang 1.6 -1.8MM, e loketseng feela bakeng sa ho itšeha. lehong le bonolo le nang le boima bo tlase. Ha u khetha botenya ba lehare la li-multi-saw, u lokela ho nahana ka botsitso ba lehare la saw le thepa e lokelang ho khaoloa.

Hona joale, e le ho fokotsa tšebeliso, lik'hamphani tse ling li se li qalile ho hlahisa li-blades tsa saw saw tse nang le lipoleiti tse nang le mahlakoreng a le mong kapa a mabeli a mahlakoreng a mabeli, mahlakoreng a mabeli a sekoti se bohareng a teteaneng, 'me karolo e ka hare ea motsoako ke. e tšesaane, ebe meno aa chesetsoa ho netefatsa botenya ba ho itšeha. Ka nako e ts'oanang, ho fihlela phello ea ho boloka thepa, botebo ba ho itšeha ha bo fete 40MM. Karolo e 'ngoe ea thepa e etselitsoe ho ba le phello ea ho fokotsa ka ho toba,' me hoa hlokahala ho kenya sesepa sa li-multi-blade. Li-blades tsa sakha bakeng sa ho poma hangata li teteane ka li-blade ho netefatsa boreleli ba ho seha.

Boleng ba li-blade saw blade bo phetha karolo ea bohlokoa, hobane motho e mong le e mong oa tseba hore li-blade saw blades ka mechine ea mapolanka li fetotsoe hore li potolohe. Ha e fetise matla a ho itšeha feela empa hape e boloka botsitso ba ho sebetsa. Li-saha tse ntle tse nang le li-multi-blade Lehare ha le na feela litekanyo tse tsitsitseng tsa geometri le ho nepahala, empa ho bohlokoa le ho feta, litšobotsi tsa eona tse matla li ntle haholo. E 'nile ea leotsoa ka makhetlo a mangata' me e na le nako e telele ea tšebeletso. Boleng ba welding ea carbide e entsoeng ka samente le bona bo bohlokoa haholo. Ha li-blades tse ngata li ntse li khaola ka mokhoa o tsoelang pele, e le hore mocheso oa boto ea saw o phahame ka potlako, 'me boto ea boleng bo phahameng e ka boloka boemo bo phahameng ba ho nepahala tabeng ena, ha lehare la saw le boleng bo bobe le tla sotha boto ea saw, e le hore meno a sakha a khone ho mamella matla a maholo a ho itšeha, ho nepahala ha lehong ho phahame haholo.