- Super User

- 2023-03-28

Na lehare la sakha le sebelisetsoang ho seha acrylic le ka sebelisoa ho seha mot

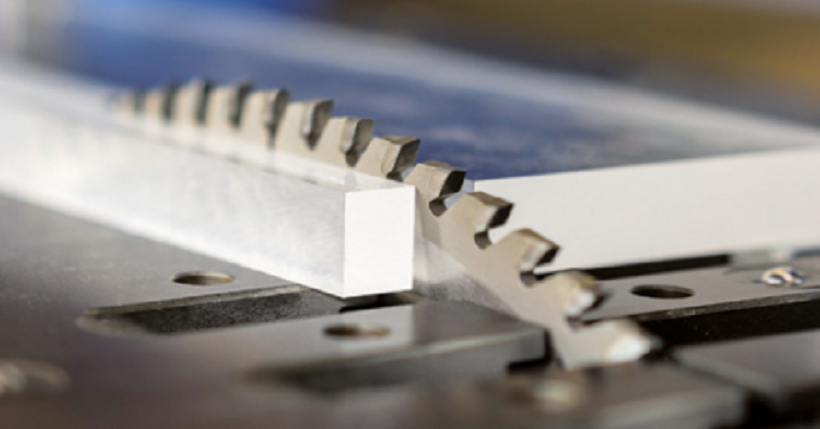

Li-saw blades tsa ho seha li-acrylic le aluminium alloys li sebelisoa haholo kahong ea tsoelo-pele ea sechaba ea sejoale-joale. Libaka tsa kaho, lifeme tsa mamati le lifensetere, lifeme tsa li-radiator, lifeme tsa thepa ea ka tlung, lifeme tsa matsoho, lifeme tsa lipoleiti, joalo-joalo kaofela ke lisebelisoa tsa bohlokoa. , bareki ba bangata ba tla ba le potso e joalo, na lehare la saw ke bokahohle? Na lehare la sakha le sebelisetsoang ho seha acrylic le ka sebelisoa ho seha motsoako oa aluminium? Na lehare le tšoanang la sakha le sebelisetsoang ho seha motsoako oa aluminium le ka sebelisoa ho seha acrylic? Karabo ke che. E, e hlile e ke ke.

Bareki ba bang ba na le mochini o le mong feela, 'me ba nahana hore ho thata ho fetola lehare la sakha. Ho khaola motsoako oa aluminium, o hloka ho sebelisa lehare le khethehileng la sakha bakeng sa ho seha motsoako oa aluminium, le ho khaola acrylic, o hloka ho sebelisa lehare le khethehileng bakeng sa ho itšeha acrylic. E-re ke u hlahlobe hore na ke hobane'ng ha lehare la sakha la ho seha acrylic le lehare la sakha la ho seha motsoako oa aluminium le ke keng la sebelisoa ka mokhoa o tšoanang.

Li-saw blades bakeng sa ho seha li-acrylic le aluminium alloys, hobane lisebelisoa tsa acrylic le aluminium alloy li fapane ebile li na le litšobotsi tse fapaneng, kahoo li-alloys tse sebelisetsoang aluminium alloy saw blades le acrylic saw blades li fapane, ke hore, mahare a fapane, acrylic e brittle ho feta. , alloy alloy e matla e phahame, e baka lialloe tse fapaneng tsa blade blade. Ea bobeli, boima bo fapane. Libopeho tsa leino tsa acrylic saw blades le aluminium alloy saw blades li fapane. Acrylic saw blade e sebelisitsoeng ho feta sebopeho sa meno ke le letšehali-le letšehali-le letona meno a bataletseng. Lehare la sakha ke lere bataletseng leino. Bareki ba sa e utloisiseng ba re ke sebopeho sa leino le leholo le le lenyenyane. Hape ke 'nete hore haeba lehare la sakha la acrylic le sebelisoa ho khaola motsoako oa aluminium, ho bonolo ho senya meno. Aluminium alloy ea lapeng e theko e tlase, 'me lehare la sakha la acrylic ha le bonolo ho le sebelisa, le amanang le acrylic crisp ha le ntle ho khaola, ho bonolo ho phatloha. Litlhoko tsa li-saw blades li phahame haholo. Hangata, acrylic e sebelisetsoa ho khaola. Ke lehare la sakha le tsoang kantle ho naha, le fapaneng ha le seha motsoako oa aluminium. Hape ho na le bahlahisi ba bangata ba malapeng. Ntle le tse ling tsa tsona boleng bo sa tsitsang, phello ea ho itšeha e boetse e ntle, 'me e ka finyella phello ea ho se be le li-burrs, empa ho bonolo ho phunya le ho lahleheloa ke meno, joalo ka ho ea ka bahlahisi ba bang ba lehare la saw, ke tloaelehileng bakeng sa di-blades sakha ho lahleheloa ke leino le le leng kapa tse peli ha seha aluminium motsoako, empa imported aluminium motsoako saha di-blades ka finyella phello ea ha ho tahlehelo ea leino kapa chipping, empa theko e phahameng ho feta ea lehae aluminium motsoako mahare a sakha a mangata, 'me theko e phahame ho feta mahare a sakha a acrylic a tsoang kantle ho naha. Baetsi ba bangata ba sebelisa li-saha tsa aluminium tsa malapeng, tseo ka kakaretso li ka sebelisoang khoeli e le 'ngoe kapa tse peli,' me li-saha tse tsoang linaheng tse ling li ka sebelisoa halofo ea selemo kapa ho feta.

Ha se hangata meno a robehang ha a sebelisoa hampe. E ka phetoa ka mor'a ho siloa ke moetsi oa setsebi. Ka kakaretso, li-blades tsa saw bakeng sa ho itšeha lisebelisoa tse fapaneng li ke ke tsa kopanngoa, 'me ha ho amohelehe ho khaola ka lehare le le leng bakeng sa boiketlo le ho boloka chelete. Ka hona, li-blades tsa saw li lokela ho neheloa ho li-blades tsa saw, 'me mahare a sakha bakeng sa ho seha li-acrylic ke tsa ho seha acrylic.