Ukuhlelwa koomatshini bentsimbi

Njengenxalenye ebaluleke kakhulu yenkqubo yokwenza isinyithi, ukusika isinyithi kudlala indima ebalulekileyo kwimveliso yezoshishino. Izixhobo zomatshini ezisetyenziselwa inkqubo yokusika isinyithi yi-Metal Cutting Saws.

Umatshini wokusika isinyithi yenye yezona zixhobo ezibalulekileyo zomatshini wokusika isinyithi, ibalwa malunga ne-6-10% yexabiso elipheleleyo lezixhobo zomatshini wokusika isinyithi kwiinkalo ezahlukeneyo zemveliso yehlabathi jikelele. Isebenzisa intshukumo ehambelanayo yesixhobo samazinyo amaninzi kunye nesixhobo sokusebenzela ukuqonda ukusarha okanye ukwenza i-contour yezinto ezahlukeneyo zetsimbi.

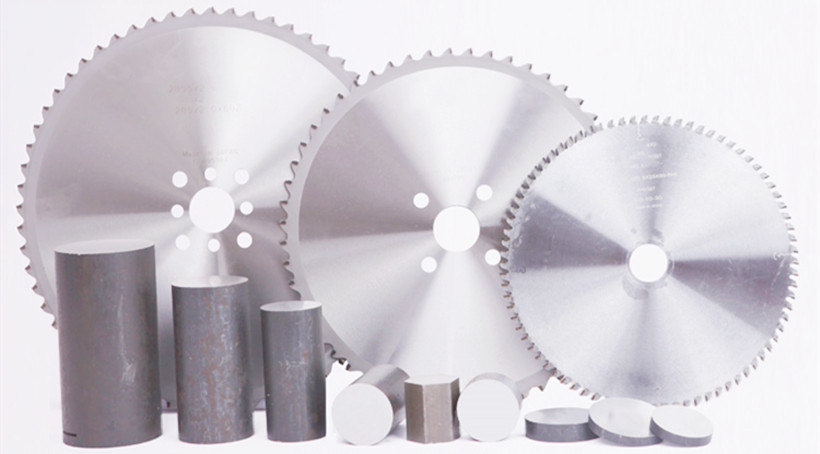

Oomatshini besinyithi besinyithi banokwahlulwa babeiisarha zokusila, iisarha zebhendi, kwayeiisarha ezibandayo.

Isarha yevili lokusila sebenzisa amavili okusila ajikeleza ngesantya esiphezulu ukusika intsimbi. Ilungele ukwakhiwa, i-hardware, i-petrochemical, i-metallurgy yomatshini, ukufakwa kombane wamanzi kunye namanye amasebe. Iyakwazi ukusika iityhubhu ezisikwere zetsimbi, iintsimbi zesikwere esisicaba, i-I-beams, iintsimbi zetshaneli kunye nezinye izinto.

I-saw yokugaya iqulunqwe ikakhulu kwisiseko, ivili lokugaya, i-motor okanye omnye umthombo wamandla, i-bracket, i-cover coverer, i-feeder yamanzi, njl njl. ihambelana nomzantsi wevili lokusila. Ibekwe phezu kwecala levili lokusila.

Isarha yevili lokugaya ikwabizwa ngokuba yisarha yokusila. Basebenzisa amavili okusila ajikeleza ngesantya esiphezulu ukusika intsimbi. Ilungele ukwakhiwa, i-hardware, i-petrochemical, i-metallurgy yomatshini, ukufakwa kombane wamanzi kunye namanye amasebe. Iyakwazi ukusika iityhubhu ezisikwere zetsimbi, iintsimbi zesikwere esisicaba, i-I-beams, iintsimbi zetshaneli kunye nezinye izinto.

I-saw yokugaya iqulunqwe ikakhulu kwisiseko, ivili lokugaya, i-motor okanye omnye umthombo wamandla, i-bracket, i-cover coverer, i-feeder yamanzi, njl njl. ihambelana nomzantsi wevili lokusila. Ibekwe phezu kwecala levili lokusila.

Ibhanti lesinyithi lesarha yebhanti libekwe ngokuthe nkqo phakathi kwamavili amabini amakhulu, anokusetyenziswa ukusika iimilo ezingaqhelekanga. I-radius ye-curve ye-saw inqunywe bubunzima be-blade. Kwinkqubo yokusarha yesinyithi, ubushushu obuveliswa yi-saw blade yabona izinyo le-workpiece buya kudluliselwa kwi-sawdust ngokusebenzisa izinyo le-sarha, kunye ne-workpiece esarha kunye ne-saw blade zigcinwa zipholile.

Ukusarha okubandayo kukusetyenziswa kwesarha yokusila ebandayo, inkqubo yokusarha ivelisa ubushushu obuncinci, unokuphepha uxinzelelo lwangaphakathi kunye notshintsho kwintlangano yempahla kwicandelo lokusikwa, ngelixa uxinzelelo lwesarha kumbhobho wentsimbi luncinci kakhulu, aluyi kubangela ukuguqulwa. udonga lombhobho kunye nomlomo wombhobho.

Ukukhethwa kwendlela yokusika isinyithi isekelwe ikakhulu kwiimfuno zokusika kumphezulu we-workpiece. Ukuba unayo nayiphi na imibuzo, nceda uqhagamshelane nathi kwaye amagcisa ethu aqeqeshiweyo aya kukuphendulela.

I-imeyile: info@donglaimetal.com