Isarha yokufaka idayimani yenye yeencakuba ezisetyenziswa ngokuxhaphakileyo. Olona phawu lukhulu lwale blade yesarha kukuba ezinye izinto ezifakelweyo zifakwe kwiblade yesarha ngeenkqubo ezahlukeneyo kwinqanaba lamva. Le blade isarha isetyenziswa kakhulu kumashishini okusika amatye kunye nekhonkrithi. Eli nqaku lazisa imisebenzi eyahlukeneyo yeencakuba zedayimani ezahlukeneyo zokufaka isarha ngokuzisa iimpawu ezithile zokufakwa kweesarha zedayimani.

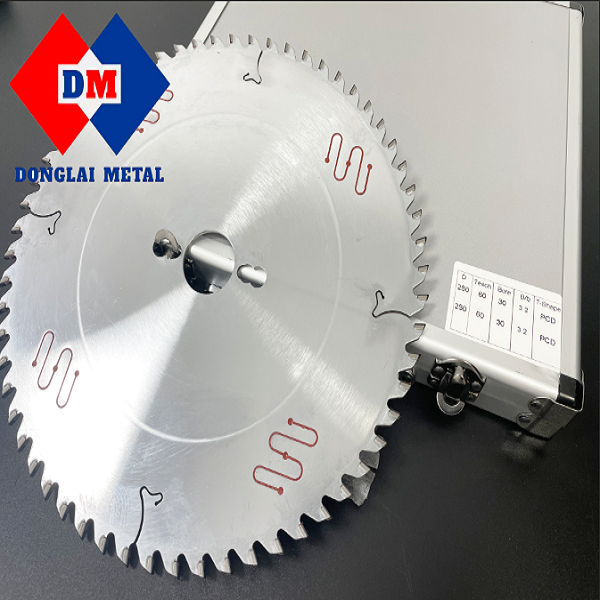

I-1: ii-PCD zedayimani zokufaka ii-saw blades.

Olu hlobo lwe-saw blade lusetyenziselwa ukusika iinkuni, kwaye lunokusetyenziselwa ukulungiswa kwamatye. Eyona nto inkulu yolu hlobo lwe-saw blade kukuba i-insert ifana ne-TCT, kodwa ulwahlulo luyingxenye yokufaka i-saw blade. Ufakelo lwenziwe nge-alloy eqinile, kwaye inkqubo esetyenziswa yi-PCD Faka isarha yesarha kukuba amanye amaphepha adibeneyo e-PCD kufuneka adityaniswe kwi-blade isarha. Ngexesha elifanayo, ubomi benkonzo yofakelo lunokuphuculwa ngakumbi. Amatye awafane aqhutywe yi-PCD. Isizathu sokuqala kukuba ixabiso le-PCD lamaphepha adibeneyo liphezulu, kunye nengxaki yokuvezwa kwedayimane, ngoko ke ukusebenza kakuhle kokusika kuya kuba kuphantsi.

2: Intsimbi yokufaka idayimani ebandayo.

Olu hlobo lwe-saw blade lucutshungulwa ngokucinezela okubandayo kunye ne-sintering. Ngenxa yeengxaki zetekhnoloji, umzimba we-blade kunye nenxalenye yentloko ye-saw blade idibene kunye. Ekubeni akukho zixhobo ezininzi zokudibanisa phakathi kwezi zibini, kwaye kukho ukungabikho kwezinto ezifanelekileyo zokudibanisa phakathi kwezi zibini, ngexesha lokucubungula, ukuba amandla okucubungula aphezulu kakhulu, kulula ukuba amazinyo e-saw blade aphume. Ngenxa yesi sizathu, ii-saw blades zofakelo olucinezelekileyo zisetyenziswa kakhulu kwii-saw blades ezinobubanzi obungaphantsi kwe-230mm. Kwinkqubo yokulungiswa kwamatye, olu hlobo lwe-saw blade lusetyenziswa ngokuqhelekileyo kwizixhobo zesandla, ezifana ne-angle grinders ebanjwe ngesandla, oomatshini bokusika ngesandla kunye nabanye oomatshini. Kukho nabanye abathengi baseVietnam abasebenzisa ii-230mm ii-saw blades ukusika amacwecwe amatye anengcaciso. Ukongeza kwiingxaki zobuchule obucothayo kunye nezinga lokusetyenziswa kwe-blade, ixabiso leyunithi lincinci, kwaye iingenelo ezininzi ezinjengokungabikho kwe-welding nazo zenza olu hlobo lwe-saw blade kwi-sawing yelitye isetyenziswe kakuhle kwinkqubo.

3: High frequency welding diamond ufakelo isarha blade.

Olu hlobo lwe-saw blade ludityanisiwe ukuze lufake icandelo ledayimani kwisiseko se-saw blade, kwaye icandelo ledayimani lidla ngokuveliswa ngokucinezela okushushu kunye ne-sintering. Ngokusebenzisa i-high-frequency soldering, i-solder idla ngokudityaniswa kwi-cutter head kunye ne-saw blade base, edla ngokuba yi-copper solder pads, i-solder pads, okanye enye i-flux. Le blade isarha inezi mpawu zilandelayo: Okokuqala, inokudityaniswa kwincakuba yesarha enkulu engenanto, enokuqinisekisa ukuba isarha yesarha enkulu ingasetyenziselwa ukusika ilitye, kwaye inokusika iibhloko ezinkulu. Okwesibini, icandelo ledayimane linokutshintshwa ngokukhawuleza, elinokusombulula ngokukhawuleza ingxaki yokugqoka kwecandelo ledayimane. Xa iseti yamacandelo edayimani itshintshwa, iblade yesarha isengaphinda isetyenziswe, nto leyo egcina ixabiso elibizileyo lokubuyisela ixabiso lesiseko sesarha. Okwesithathu, amandla e-welding aphezulu aphezulu. Ukuba ithebhu ye-solder enengqiqo kunye ne-solder isetyenziselwa ukudibanisa, amandla e-welding yecandelo ledayimani liphezulu kakhulu. Ukungabikho kweemeko eziphezulu zokushisa, ukuchasana kwempembelelo kunye nokugoba ukugoba kolu kufakwa kuyafumaneka kwaye kufanelekileyo kuyo yonke ilitye lokusika. Okwesine, iindleko zoomatshini be-welding zangoku ziphantsi, kwaye kulula ukwenza i-welding processing, kwaye i-factory inokuqonda iimeko ze-welding processing processing ngexabiso eliphantsi.

I-4: I-Laser diamond ifaka i-saw blade.

Olu hlobo lweblade yesarha lutshisa iinxalenye zesarha yesiseko esingenanto kunye namacandelo edayimani ngelaser, kwaye ezi ndawo zimbini zidlula kubushushu obuphezulu ukwenza izinto ezintsha zealloy. Amandla ale mathiriyeli ye-alloy iphezulu kakhulu kunaleyo ye-welding material,nokuba amatyeli aliqela phezulu, ke eyona nzuzo inkulu kweli phepha lelaser kukuba amandla okuwelda aphezulu, kwaye anokusika ezinye izinto ezinzima. Ngokomzekelo, ikhonkrithi eyomeleziweyo, ukusika umzimba we-metal ore, njl., Inokunqunyulwa ngale ndlela yokusika. Ngokuphathelele ukusetyenziswa kwamatye, ngenxa yokuba i-laser sheet ikwinkqubo ye-welding, ngokwenene ibangela ukuguqulwa okuncinci kumzimba weshidi, kwaye kunzima ukuyiphatha kwinkqubo yokuqhawula kamva yecandelo ledayimani. Ngoko ke, kwishishini lokulungisa amatye, abavelisi abambalwa basebenzisa le ndlela. Ngaphandle kokuba kukho iimfuno ezikhethekileyo zokusika, ezifana nokusika okomileyo, njengobunzima obuphezulu belitye, njl., Kule meko ekhethekileyo, i-laser welding sheet ingasetyenziselwa ukusika ilitye.

I-5: I-Brazing kunye ne-electroplating saw blades.

Ezona blade zesarha zedayimani zangaphambili zavezwa ngokufakwa kwedayimani kwisarha yesarha engaphantsi, kwaye le ndlela isenokusetyenziswa njengereferensi. Idayimane igxininiswe kumphezulu we-saw blade nge-electroplating kunye ne-vacuum brazing, kwaye inkqubo yokusika igqitywe ngokusika ilitye ngedayimane phezu kobuso be-saw blade. Olu hlobo lwe-saw blade lusetyenziselwa ukusika ilitye elomileyo, ngakumbi ukusika ukusebenza kakuhle. Olu hlobo lwe-saw blade lunokuphucula kakhulu ukusebenza kakuhle kokusika kwaye aluchaphazeleki kwimeko yangaphandle.

Ukuqukumbela, i-diamond yokufaka isarha yesarha ibaluleke kakhulu ekusikeni amatye. Kunokuthiwa ukufakwa kwamatye kunokuhlangabezana phantse nazo zonke iimfuno zokusika zamatye, kwaye ukusebenza kwezi blades zesarha kuya kuba namandla amakhulu ophuhliso kwixesha elizayo.