Ukuze wenze i-saw blade idlale ukusebenza kwayo kakuhle, kufuneka isetyenziswe ngokungqongqo ngokuhambelana neenkcukacha;

1. I-Saw blade eneenkcukacha ezahlukeneyo kunye nokusetyenziswa zineengile ezahlukeneyo zoyilo kunye ne-saw blank, ngoko zama ukuzisebenzisa ngokwezihlandlo ezihambelanayo;

2. Ubungakanani kunye nokuchaneka kobume be-shaft ephambili kunye ne-splint yezixhobo zinempembelelo enkulu kwimpembelelo yokusetyenziswa, ngoko jonga kwaye ulungelelanise ngaphambi kokufaka i-saw blade. Ngokukodwa, izinto ezichaphazela i-clamping force kwindawo yokudibanisa phakathi kwe-splint kunye ne-saw blade kwaye ibangele ukufuduka kunye ne-slippage kufuneka isuswe;

3. Nika ingqalelo kwimeko yokusebenza ye-saw blade nanini na. Ukuba kukho nakuphi na ukungaqhelekanga okwenzekayo, njengokungcangcazela, ingxolo, kunye nokutya okubonakalayo kwindawo yokucubungula, kufuneka kumiswe ngexesha lokulungelelanisa, kwaye kufuneka kulungiswe ngexesha ukuze kugcinwe ubukhali;

4. Musa ukutshintsha i-angle yokuqala xa ugaya i-saw blade, ukwenzela ukuba ugweme ukushisa ngokukhawuleza kwendawo kunye nokupholisa ngokukhawuleza kwentloko ye-blade. Kungcono ukubuza ukugaya okuqeqeshiweyo

5. Iisarha zesarha ezingasetyenziswayo okwangoku kufuneka zixhonywe ngokuthe nkqo ukuphepha ukubekwa mcaba ixesha elide, kwaye izinto akufanele zifunjwe phezu kwayo. Incakuba kufuneka ikhuselwe ekungqubekeni.

6. Isixhobo ngokwaso kufuneka sibe neempawu ezintle zoomatshini, zifakwe ngokuqinileyo kwaye zilungiswe, kwaye zingabikho ukungcangcazela;

7. Umphezulu weflange kufuneka ucoceke, ucwecwe kwaye ulungelelanise omnye nomnye.

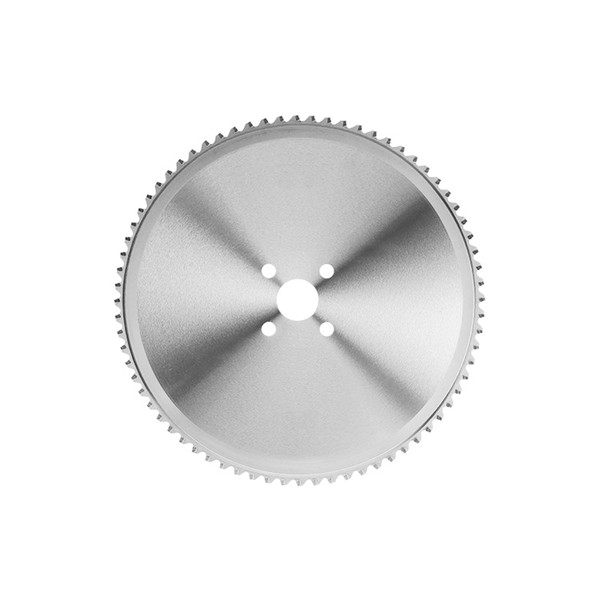

8. I-diameter ye-flange kufuneka ilingane okanye ikhulu kune-1/3 yobubanzi be-saw blade esetyenzisiweyo. Ukuba i-flange incinci kakhulu, nangona i-saw blade ehamba phambili kwimarike isetyenzisiweyo, iziphumo ezinganelisekanga ziya kwenzeka.

9. I-shaft ephambili yezixhobo zoomatshini kufuneka ibe flat kwaye iqonde, kwaye ukunyamezela akufanele kube ngaphantsi komgangatho wesizwe. Umgangatho wesizwe wokunyamezela i-shaft engundoqo yi-±0.01mm.

10. I-saw blade inemvakalelo ebuthuntu. Xa ukugaya ngexesha likaxakeka, ivili lokugaya idayimane elinomlinganiselo ofanelekileyo we-particle kufuneka likhethwe, kunye ne-coolant kufuneka isetyenziswe kunye; emva kokugaya, i-angle yokusika ye-original yezinyo kufuneka igcinwe, kwaye i-angle yangasemva kunye nebhodi ye-sawboard Ukugaya kunye nokulungiswa kufuneka kwenziwe ngexesha elifanayo, ukwenzela ukuba iziphumo ezanelisayo zifezekiswe. Okwangoku, kukho izixhobo ezininzi zokugaya kwiimarike, kodwa ukuchaneka kunye neemeko zokugaya izixhobo ngokwazo azikwazi ukuhlangabezana neemfuno, zingabikho ukugaya iimveliso ezilungileyo.

11. Ngaphambi kokusebenzisa i-saw blade entsha okanye yomhlaba, kufuneka ibe yi-idling kumjikelo, kwaye emva koko ukhangele ukuba i-saw blade ifakwe ngokuqinileyo ukukhusela i-saw blade ukuba ingatyibiliki.

12. Ukubuyiselwa kwakhona kweblade yesarha akufuneki kudlule kwindawo yokuqala yokuvula i-15mm. Ngenxa yokuba umenzi ngamnye we-saw blade ulungelelanise uxinzelelo lwe-saw blade ngokobubanzi balo ngaphambi kokuba i-saw blade iphume kumzi-mveliso, kungenjalo iya kubangela ukulahlekelwa kwengcinezelo kunye nesiphumo sokusika i-blade yesarha siya kuchaphazeleka. .

13. Khetha inani elifanelekileyo lamazinyo, elihambelana ngakumbi nesiphumo sokusika kunye nokwandiswa kobomi benkonzo ye-saw blade.