Kutheni i-saw blade entsha ingekho kakuhle njenge-saw blade endala emva kokutshintshwa ngomatshini? Ngokwempendulo ebanzi yabasebenzisi, kukho iiglitches, amazwi angxolayo, kunye neendawo ezisikiweyo. Ziziphi izizathu zezi ngxaki? Umhleli olandelayo uya kukuxelela ukuba kutheni le meko isenzeka kunye nendlela yokuyisombulula.

Kutheni i-saw blade entsha ingekho kakuhle njenge-saw blade endala emva kokutshintshwa ngomatshini? Ngokwempendulo ebanzi yabasebenzisi, kukho iiglitches, amazwi angxolayo, kunye neendawo ezisikiweyo. Ziziphi izizathu zezi ngxaki? Umhleli olandelayo uya kukuxelela ukuba kutheni le meko isenzeka kunye nendlela yokuyisombulula.

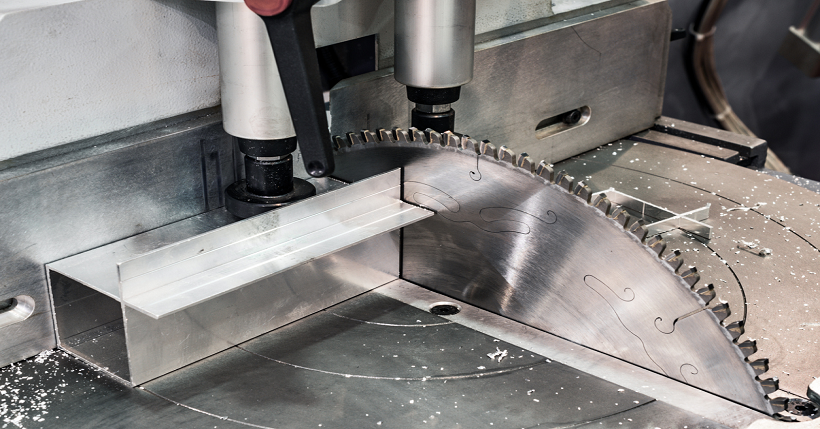

Isizathu 1: I-spindle iyaguga kwaye igugile; khangela ukuphuma kwe-spindle ngaphambi kokutshintsha i-saw blade. Ukuba ukuphuma kugqithise kuluhlu olufanelekileyo, i-saw blade iya kuphambuka, okukhokelela kwi-burrs kwi-workpiece yesarha. Kuyimfuneko ukuyeka ukusebenza ngexesha kwaye ubuyisele i-spindle.

Isizathu 2: Kukho izinto zangaphandle kwiflange; njengoko igama libonisa, kukho izinto zangaphandle kwiflange, okuthetha ukuba kukho iitshiphusi zealuminiyam kunye namabala kwipleyiti yoxinzelelo elungisa isarha, iblade yesarha ayifakwanga ngeli xesha umsebenzi wokusarha uya kuba ne-burr, isenzeko esikhulu. , ngoko ke umhleli ucebisa ukuba kufuneka ujonge iflange ukunqanda ukulayisha okwesibini kunye nokukhulula isarha blade.

Isizathu 3: Ingaba ioli yokuthambisa yanele; uchungechunge lomsebenzi wokulungiselela kufuneka lwenziwe ngaphambi kokufaka i-saw blade. Ukuthambisa ioli ngumsebenzi obalulekileyo. Ukusebenzisa i-oyile yokuthambisa kunokunciphisa ukungqubana phakathi kwamazinyo esarha kunye ne-workpiece ukuze kungabikho isarha kwindawo yokumakisha iphinda iqhubele phambili ubomi benkonzo yesarha.

Isizathu 4: Ukubuyisela ngexesha ibhodi ye-bakelite esele igugile kwaye ikhubazekile ngenxa yokulungiswa kwexesha elide. Ukuba ibhodi ye-bakelite igugile, iya kubangela ukuba isikhundla sezinto eziphathekayo sitshintshe emva kokuba i-workpiece inqunyulwe, kwaye i-saw blade iya kutshabalalisa imela ngokungqongqo ngexesha lenkqubo yokubuyisela imela (ukuchukumisa izinto ), okubangelwa yi-glitches.