Abathengi abaninzi bayayihoya ezinye "iindlela ezincinci" zokugcina kunye nokukhusela isarha yesarha xa usebenzisa isarha yesarha, okukhokelela ekubeni iblade isarha enye ibe novavanyo olwahluke ngokupheleleyo ezandleni zabathengi abohlukeneyo.

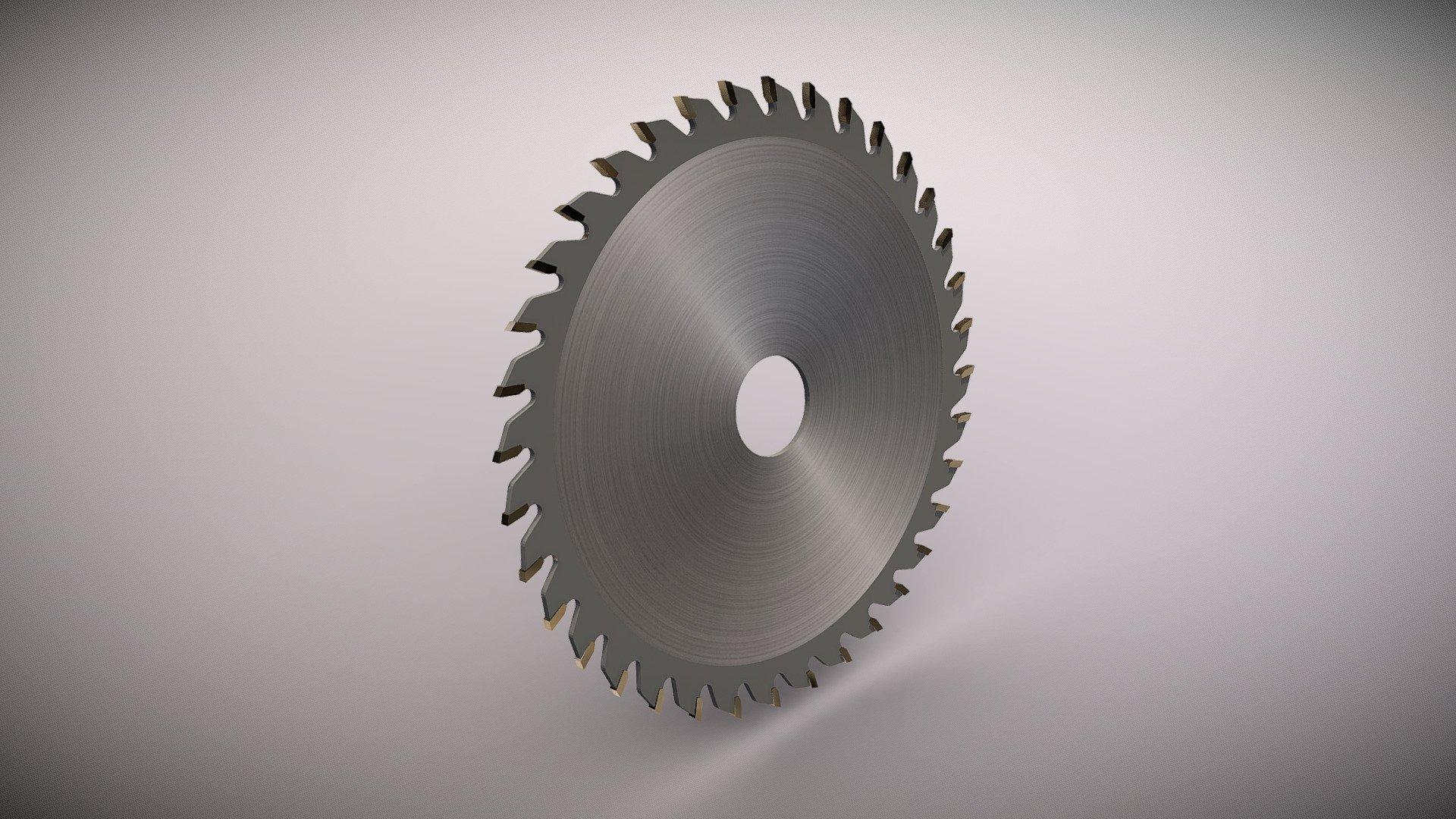

1. Ukuba i-saw blade ayisetyenziswanga ngokukhawuleza, kufuneka ibekwe phantsi okanye ixhonywe ngokusebenzisa umngxuma wangaphakathi. Musa ukupakisha ezinye izinto okanye ukunyathela i-blade isarha ebekwe tyaba, kwaye ubeke ingqalelo kumanzi kunye nokuhlwa.

2. Xa i-saw blade ingasabukhali kwaye indawo yokusika ilukhuni, kufuneka ihlaziywe ngexesha. Ukugaya akukwazi ukutshintsha i-angle yokuqala kwaye kutshabalalise ibhalansi eguqukayo.

3. Ukulungiswa kwedayimitha engaphakathi kunye nokusetyenzwa komngxuma wokumisa weblade isarha kufuneka kwenziwe ngumzi-mveliso. Ukuba inkqubo ayilunganga, iya kuchaphazela isiphumo sokusetyenziswa kwemveliso kwaye inokubangela ingozi. Ngokomgaqo, umngxuma wokubuyisela akufanele udlule ubungakanani bomngxuma wokuqala we-20mm, ukuze ungachaphazeli ukulinganisela koxinzelelo.

Isine. Ukukhetha ivili lokugaya i-alloy.

I-1) Amandla okudibanisa i-resin ebotshelelwe ivili lokusila idayimani ibuthathaka, ngoko ke ukuzibukhali kunokuba kuhle ngexesha lokusila, akulula ukuvala, ukusebenza kakuhle kokusila kuphezulu, amandla okusila ancinci, kwaye ubushushu bokugaya bulungile. phantsi. Okungalunganga kukunganyangeki kokunxiba kunye nokunxiba kwe-abrasive Enkulu, ayifanelekanga ukugaya umsebenzi onzima.

I-2) Ivili lokusila ledayimane eligubungele i-Vitrified bond lingcono ukunxiba kunye nokukwazi ukubopha kune-resin bond, ukusika okubukhali, ukusebenza kakuhle kokusila, akukho lula ukuvelisa ubushushu kunye nokuvala, ukwanda okuncinci kwe-thermal, kulula ukulawula ukuchaneka, ukungabikho kokungahambi kakuhle kunye neendleko eziphezulu. .

I-3) Ivili lokugaya idayimani yentsimbi inamandla okubambisana okuphezulu, ukuxhathisa kakuhle, ukunxiba okuphantsi, ubomi obude, ixabiso eliphantsi lokugaya, kwaye linokumelana nemithwalo emikhulu, kodwa inobukhali obunzima kwaye kulula ukuyivala.

I-4) Ubungakanani be-particle abrasive inefuthe elithile kwi-clogging kunye nokusika umthamo wevili lokugaya. Xa kuthelekiswa ne-fine grit, i-coarse grit iya kwandisa ukunxiba kwe-cut cut xa ubunzulu bokusika bukhulu, ngaphandle koko ivili lokugaya kulula ukulivala.

I-5) Ukuqina kwevili lokugaya kunempembelelo enkulu kwi-clogging. Ubunzima obuphezulu bevili lokugaya linomgangatho ophezulu we-thermal conductivity, ongenakulungelelaniswa nokutshatyalaliswa kobushushu bomhlaba, kodwa kunenzuzo ekuphuculeni ukuchaneka kokucubungula kunye nokuqina.

I-6) Ukukhethwa kokugxininiswa kwevili lokugaya kuyisici esibalulekileyo, esinempembelelo enkulu ekusebenzeni kakuhle kunye neendleko zokucubungula. Ukuba ugxininiso luphantsi kakhulu, ukusebenza kakuhle kuya kuchaphazeleka. Kungenjalo, iinkozo ezirhabaxa ziya kuwa lula, kodwa olona luhlu logxininiso lwebhondi lulungile.