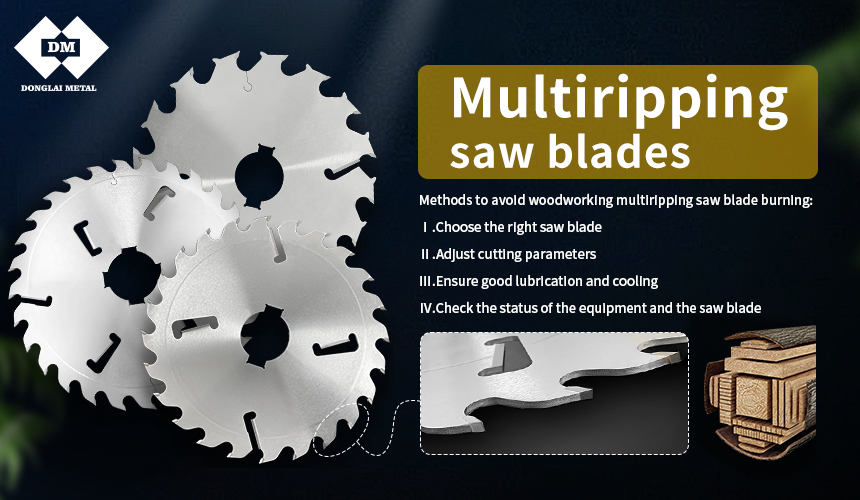

Nazi ezinye zeendlela zokuphepha i-Woodri Goodrications ezininziripping Wabona i-blade evuthayo:

Ⅰ.choose I-Blade yasekunene

Khetha i-Blad Blade ngohlobo lweenkuni, ubukhali kunye nokuthambisa. Kwimithi ye-ostwood, njengepine, iimfuno ze-blade zekhefu zinokusezantsi kancinci.

Inani lamazinyo kwi-Blade ye-Blade kufuneka libe lelokwayini.A yabona i-blade enamazinyo angagungqiyo, kodwa inesithuba esingaphantsi kwe-chip kwaye kulula ukugqitha kwi-chip yokususa, kodwa Umphezulu wokusika usenokuba rhabaxa.

Ⅱ.Lungisa iiparameter ezisikiweyo

Isantya sokusika isantya.Ukuba isantya esisikiweyo ngokukhawuleza kakhulu, ukuxabana phakathi kwe-Blade yeBlade kwaye iinkuni ziya kuvelisa ubushushu obuninzi, ezinokuthi zitshise isantya esifanelekileyo ngokobubanzi beBlade yeBlade kunye nezinto zenkuni.

Ixabiso lokutya kufuneka libe lelokwakhona.usona sixa semali esikhulu kakhulu, i-blade yabona iya kuthwala kakhulu, oya kubangela iqondo lobushushu liphezulu kakhulu.

Ⅲ.Ukuthobela izinto ezintle kunye nokupholisa

Ukusikeka kobungcali kunokusetyenziswa.Coute ukuntywila akunakudlala indima yokupholisa, kodwa ikwanciphisa ukungqubana phakathi kwe-Blade yeBlade kunye neenkuni.

Ezinye izixhobo zixhotyiswe ngezixhobo zokupholisa. Qinisekisa ukuba isixhobo sokupholisa sisebenza ngesiqhelo ukuze i-saw blade ipholile ngokupheleleyo ngexesha lenkqubo yokusebenza.

Ⅳ.Check imeko yezixhobo kunye ne-Blade yeBlade

Jonga ukungcola kunye nokubukhali kwe-sawde ye-Blade rhoqo. Ukuba i-Blade yeBlade iphela okanye i-blunted, ukuxhathisa ngexesha lokusika kuya kunyuka kwaye amaqondo amaqondo aphezulu aya kwenziwa ngokulula.

Gcina ukuchaneka kwezixhobo, njengokuchaneka kweShaft yakho. Ukuba i-Shaft yeWep iphazamisekile, i-blad yabona iya kushukumisa xa utyano, yandisa ukungqubana, kwaye ibangele blade ukuba itshise.