I-Diamond insert saw blade ingenye yezinhlamvu ezivame ukusetshenziswa kakhulu. Isici esikhulu kunazo zonke sale blade yesaha ukuthi okunye okufakwayo kufakwe ku-saha blade ngezinqubo ezahlukahlukene esigabeni sakamuva. Le blade yamasaha isetshenziswa kakhulu ezimbonini zokusika amatshe nezikhonkolo. Lesi sihloko sethula ukusebenza okuhlukile kwama-saha wedayimane ahlukahlukene ngokwethula izici ezithile zamasaha okufaka idayimane.

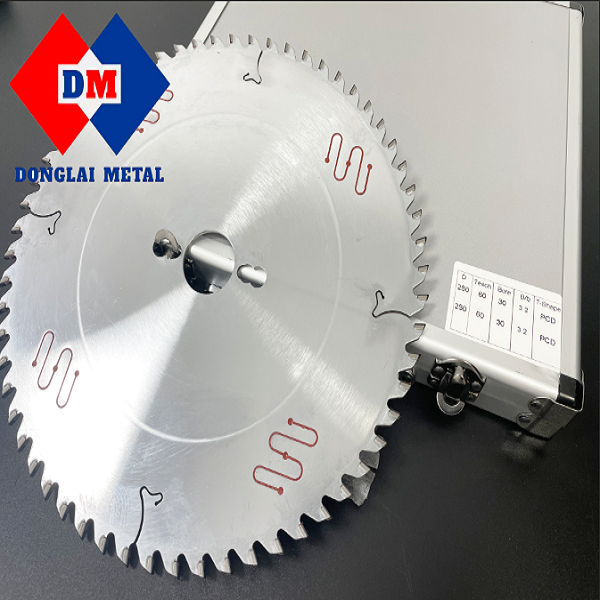

1: PCD diamond insert saw blades.

Lolu hlobo lwe-saw blade lusetshenziselwa ukusika izinkuni, futhi lungasetshenziselwa ukucubungula amatshe. Isici esikhulu salolu hlobo lwe-saw blade ukuthi ukufakwa kufana ne-TCT, kodwa umehluko yingxenye yokufaka ye-saw blade. Izinto ezifakiwe zenziwe nge-hard alloy, futhi inqubo esetshenziswa i-PCD insert saw blade iwukuthi amanye amashidi ayinhlanganisela ye-PCD adinga ukushiselwa ku-saha blade. Ngesikhathi esifanayo, impilo yesevisi yokufaka nayo ingathuthukiswa nakakhulu. Amatshe awavamile ukucutshungulwa yi-PCD. Isizathu sokuqala ukuthi intengo yamashidi ayinhlanganisela ye-PCD iphezulu, futhi inkinga yokuchayeka kwedayimane, ngakho-ke ukusebenza kahle kokusika kuzoba phansi.

2: Isaha lesaha ledayimane elicindezelwe ngokubanda.

Lolu hlobo lwe-saw blade lucutshungulwa ngokucindezela okubandayo nokucwiliswa. Ngenxa yezinkinga zobuchwepheshe, umzimba we-blade kanye nengxenye yekhanda ye-saw blade empeleni kuhlanganiswe ndawonye. Njengoba zingekho izindawo eziningi zokuxhuma phakathi kokubili, futhi kukhona ukuntuleka kwezinto ezifanele zokuxhuma phakathi kokubili, ngesikhathi sokucubungula, uma amandla okucubungula aphezulu kakhulu, kulula ukuthi amazinyo e-saw blade aphume. Ngenxa yalesi sizathu, amasaha okufakwa okucindezelwe okubandayo asetshenziswa kakhulu kumasaha anobubanzi obungaphansi kuka-230mm. Enqubweni yokucubungula amatshe, lolu hlobo lwe-saw blade luvame ukusetshenziswa kakhulu kumathuluzi ezandla, njengama-angle grinders aphethwe ngesandla, imishini yokusika ebanjwa ngesandla neminye imishini. Kukhona namakhasimende athile aseVietnam asebenzisa amasaha angama-230mm ukusika ama-slabs amatshe anemininingwane. Ngaphezu kwezinkinga zokusebenza kancane kanye nezinga eliphansi lokusebenzisa i-blade, intengo yeyunithi ishibhile, futhi izinzuzo eziningi ezinjengokungabikho kwe-welding nazo zenza lolu hlobo lwe-saw blade ekuboneni amatshe lusetshenziswe kahle kule nqubo.

3: I-high frequency welding diamond ifaka i-saw blade.

Lolu hlobo lwe-saw blade lushiselwe ukufaka ingxenye yedayimane esisekelweni se-saw blade, futhi ingxenye yedayimane ivame ukukhiqizwa ngokucindezela okushisayo nokucwiliswa. Ngokusebenzisa i-high-frequency soldering, i-solder ivame ukungezwa ekhanda lokusika kanye nesisekelo se-saw blade, okuvame ukuba amaphedi e-copper solder, ama-solder pads, noma enye i-flux. Le blade yesaha inezici ezilandelayo: Okokuqala, ingashiselwa empahleni enkulu yesaha engenalutho, engaqinisekisa ukuthi isayizi enkulu yesaha ingasetshenziswa ukusika itshe, futhi ingasika amabhlogo amakhulu. Okwesibili, ingxenye yedayimane ingashintshwa ngokushesha, engaxazulula ngokushesha inkinga yokugqoka kwengxenye yedayimane. Lapho isethi yamasegimenti edayimane ishintshwa, i-saw blade isengaphinda isetshenziswe, okusindisa izindleko ezibizayo zokushintshwa kwesisekelo se-saw blade. Okwesithathu, amandla e-welding aphezulu aphezulu. Uma ithebhu ye-solder enengqondo isetshenziselwa ukushisela, amandla okushisela wengxenye yedayimane aphezulu kakhulu. Uma kungabikho izimo zokushisa eziphakeme, ukumelana nomthelela kanye nokumelana nokugoba kwalokhu kufakwa kuyatholakala futhi kulungele konke ukusika kwamatshe. Okwesine, izindleko zamanje zemishini yokushisela ziphansi, futhi kulula ukwenza ukucubungula kwe-welding, futhi imboni ingakwazi ukubona izimo zokucubungula okuzimele ngenani eliphansi.

4: I-laser diamond inserts saw blade.

Lolu hlobo lwe-saha blade lushisisa izingxenye zesisekelo sesaha zingenalutho kanye nezingxenye zedayimane kusetshenziswa i-laser, futhi lezi zindawo ezimbili zidlula ezingeni lokushisa eliphezulu ukuze zenze izinto ezintsha zengxubevange. Amandla ale nto ye-alloy aphakeme kakhulu kunaleyo yezinto zokushisela,ngisho nangaphezulu izikhathi eziningana, ngakho-ke inzuzo enkulu yaleli shidi le-laser ukuthi amandla okushisela aphezulu, futhi angasika ezinye izinto eziqinile. Isibonelo, ukhonkolo oqinisiwe, ukusika umzimba wensimbi yensimbi, njll., kungasikwa ngale ndlela yokusika. Mayelana nokusetshenziswa kwamatshe, ngenxa yokuthi ishidi le-laser lisenqubweni yokushisela, empeleni libangela ukuwohloka okuncane emzimbeni weshidi, futhi kunzima ukuphatha inqubo yokuhlakazwa kamuva kwengxenye yedayimane. Ngakho-ke, embonini yokucubungula amatshe, abakhiqizi abambalwa basebenzisa le ndlela. Ngaphandle uma kunezidingo ezikhethekile zokusika, njengokusika okomile, njengokuqina okuphezulu kwetshe, njll., kulezi zimo ezikhethekile, ishidi le-laser welding lingasetshenziswa ukusika itshe.

5: I-Brazing kanye ne-electroplating saw blades yedayimane.

Ama-blade amasaha edayimane okuqala ayevezwa ngamadayimane afakwe endaweni engaphansi ye-saha blade, futhi le ndlela isengasetshenziselwa ireferensi. Idayimane liqiniswe ebusweni be-saw blade nge-electroplating ne-vacuum brazing, futhi inqubo yokusika iqedwa ngokusika itshe ngedayimane ebusweni be-saw blade. Lolu hlobo lwe-saw blade lusetshenziselwa kakhulu ukusika amatshe omile, ikakhulukazi ukusika ukusebenza kahle. Lolu hlobo lwe-saw blade lungathuthukisa kakhulu ukusebenza kahle kokusika futhi aluthintwa imvelo yangaphandle.

Sengiphetha, i-saw blade yedayimane ibaluleke kakhulu ekuqoqweni kwamatshe. Kungashiwo ukuthi ukufakwa kwamatshe kungahlangabezana cishe nazo zonke izidingo zokusika zamatshe, futhi ukusebenza kwalawa ma-saw blades kuzoba namandla amakhulu okuthuthukiswa esikhathini esizayo.