I-Cold Cut SawvsI-Hot Cut Saw

Isaha elibandayo lokusika: Insimbi inqunywa ngokushesha ngensingo eyindilinga ezungeza ngesivinini esisezingeni lokushisa elilingana negumbi, kanti indawo yokugcina ibushelelezi futhi ihlanzeke njengesibuko.

Isaha elishisayo elishisayo: elivame ukubizwa ngokuthi isaha lokugenca, isaha elindizayo lekhompyutha, elibizwa nangokuthi isaha friction. Ukusika ngesivinini esiphezulu kuhambisana nokushisa okuphezulu kanye nezinhlansi, indawo yokuphela kokusika insomi, futhi kukhona ukukhanya okuningi nama-burrs.

Indlela yokusaha:

Isaha elibandayo lokusika: Isaha yensimbi enesivinini esikhulu izungeza kancane ukuze igaye ipayipi elishiselwe, ukuze ingabhabhuli futhi ingabi namsindo. Inqubo yokusaha ikhiqiza ukushisa okuncane kakhulu, futhi i-saw blade icindezela kancane ipayipi lensimbi, elingeke libangele ukuguqulwa kwe-orifice yodonga lwamapayipi.

Isaha elishisayo lokusika: Isaha elindizayo lekhompyutha elivamile liyinsingo yesaha yensimbi ye-tungsten ezungeza ngesivinini esikhulu, futhi ukushisa okukhiqizwa ngokuthinta ipayipi elishiselwe kubangela ukuba liphuke, elishiswe ngempela. Izimpawu zokusha okuphezulu zibonakala phezulu. Ukushisa okuningi kukhiqizwa, futhi i-saw blade icindezela kakhulu ipayipi lensimbi, okubangela ukuguqulwa kodonga lwamapayipi kanye nozzle kubangele ukukhubazeka kwekhwalithi.

Ukunemba kobude:

Isaha lokusika elibandayo: ubude obumisiwe ± 2.0mm, ukunemba kokuphindaphinda kokucaciswa okufanayo ± 0.5mm, asikho isidingo sokulinganisa kwesibili, inqubo yokonga nezinto ezingavuthiwe

Isaha lokusika elishisayo: ±2.5mm, iningi lazo lidinga ukusikwa libe lide lingaxhunyiwe ku-inthanethi kabili, okumosha amandla omuntu nezinto zokusetshenziswa

Sika ikhwalithi:

I-Cold-cut saw: ama-burrs amancane angaphakathi nangaphandle, indawo yokugaya ebushelelezi futhi ebushelelezi, asikho isidingo sokucutshungulwa kokulandelela, izinqubo zokulondoloza kanye nezinto zokusetshenziswa

I-hot-cut saw: Ama-burrs angaphakathi nangaphandle makhulu kakhulu, futhi ukucubungula okulandelayo njenge-flathead chamfering kuyadingeka, okwandisa izindleko zamandla abasebenzi kanye nokusetshenziswa kwempahla eluhlaza.

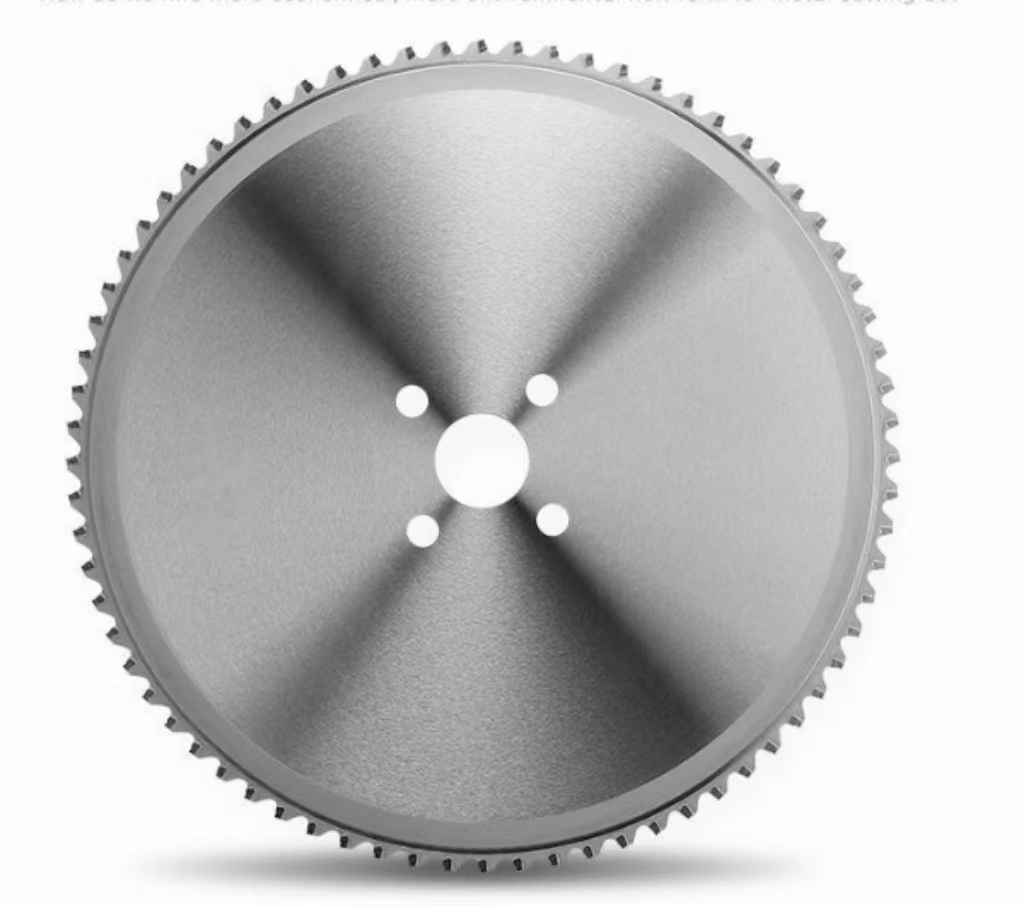

Ingabe umehluko phakathi kwe-saw cut cut kanye ne-hot cut saw i-saw blade?

Ngokusobala, ukukhetha i-saw blade yekhwalithi enhle kungenye yezici zokuthola umphumela omuhle wokusaha. Ngesikhathi esifanayo, kunezici eziningi ezijulile nezibaluleke kakhulu ezithinta umphumela wokusaha. Isibonelo, ukudlidliza okungavamile okukhiqizwa lapho umshini wokusaha ugijima, igebe legiya likhulu kakhulu, amandla emoto mancane kakhulu, ukusetshenziswa kwezinto ezilungiswayo kanye nenani lokupholisa akufanelekile, isaha Isivinini somshini siphezulu kakhulu, sihamba kancane kakhulu. isivinini sokuphakelayo njll kuzodala umonakalo ku-saw blade futhi kuthinte umphumela wokusaha. Ngakho-ke, ikhwalithi yomshini we-saw endizayo kanye nemingcele yohlelo lokusebenza yokubona ithinta ngokuqondile ikhwalithi yokubona ye-workpiece, ukusebenza kahle kwe-sawing kanye nempilo yesevisi ye-saw blade. Imishini yokusaha esekelayo + imingcele yokusaha esezingeni eliphakeme + i-saw blade yekhwalithi ephezulu + imingcele ye-saw blade = umphumela wokusaha wekhwalithi ephezulu