Amakhasimende amaningi awanaki ezinye "izindlela ezincane" zokugcina nokuvikela i-saw blade lapho usebenzisa i-saw blade, okuholela ekutheni i-saha blade ibe nokuhlola okuhluke ngokuphelele ezandleni zamakhasimende ahlukene.

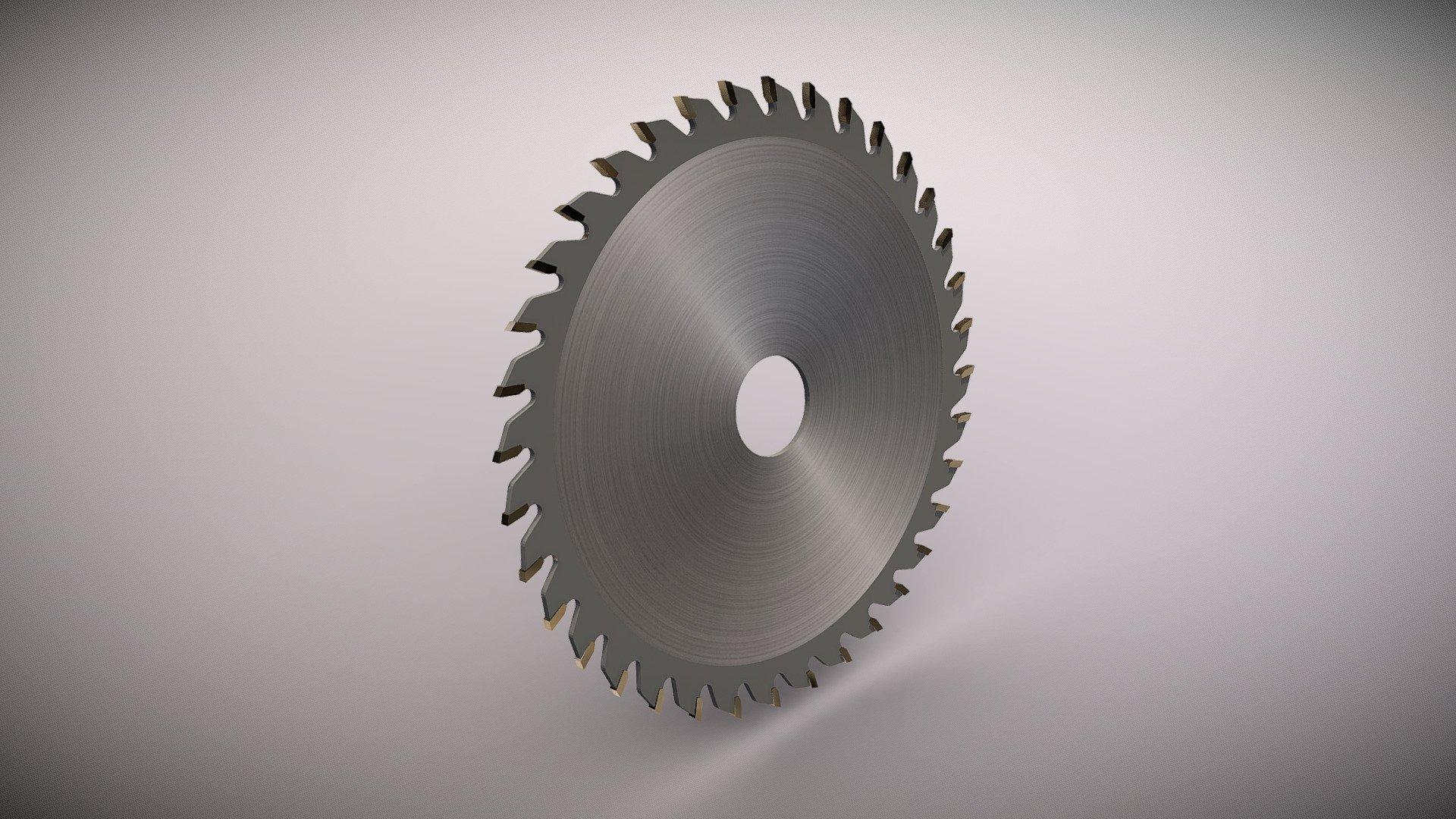

1. Uma i-saw blade ingasetshenziswa ngokushesha, kufanele ibekwe phansi noma ilengiswe ngokusebenzisa imbobo yangaphakathi. Ungapakishi ezinye izinto noma unyathele i-saw blade ebekwe phansi, futhi unake umswakama nokugqwala.

2. Uma i-saw blade ingasabukhali futhi indawo yokusika ilukhuni, kufanele ifakwe kabusha ngesikhathi. Ukugaya akukwazi ukushintsha i-engeli yokuqala futhi kucekele phansi ibhalansi eguqukayo.

3. Ukulungiswa kwe-diameter yangaphakathi kanye nokucutshungulwa kwembobo yokubeka indawo ye-saw blade kumele kwenziwe ifektri. Uma ukucutshungulwa kungasebenzi, kuzothinta umphumela wokusetshenziswa komkhiqizo futhi kungase kubangele ingozi. Eqinisweni, imbobo yokubuyisela kabusha akufanele idlule ububanzi bomgodi wokuqala we-20mm, ukuze ungaphazamisi ibhalansi yokucindezeleka.

Ezine. Ukukhetha isondo lokugaya ingxubevange.

1) Amandla okubopha wesondo lokugaya idayimane eliboshwe nge-resin abuthakathaka, ngakho-ke ukuzicija kungaba kuhle ngesikhathi sokugaya, akulula ukuvala, ukusebenza kahle kokugaya kuphezulu, amandla okugaya mancane, futhi izinga lokushisa lokugaya phansi. Okubi wukumelana nokugqokwa okungekuhle nokugqokwa kwe-abrasive Okukhulu, akufanelekile ukugaya umsebenzi osindayo.

2) Isondo lokugaya ledayimane le-Vitrified linamandla okumelana nokugqoka kanye nekhono lokubopha kune-resin bond, ukusika okubukhali, ukusebenza kahle kokugaya okuphezulu, akulula ukukhiqiza ukushisa nokuvala, ukunwetshwa okuncane okushisayo, ukulawula ukunemba okulula, ukungalungi indawo yokugaya kanye nezindleko eziphezulu. .

3) Isondo lokugaya idayimane lensimbi linamandla okubopha okuphezulu, ukumelana nokugqokwa okuhle, ukugqoka okuphansi, impilo ende, izindleko eziphansi zokugaya, futhi lingakwazi ukumelana nemithwalo emikhulu, kodwa linobukhali obumpofu futhi kulula ukuvala.

I-4) Usayizi wezinhlayiya ze-abrasive unethonya elithile kumthamo wokuvala nokusika wesondo lokugaya. Uma kuqhathaniswa ne-grit emihle, i-coarse grit izokwandisa ukugqoka komkhawulo wokusika lapho ukujula kokusika kukhulu, ngaphandle kwalokho isondo lokugaya kulula ukulivala.

I-5) Ukuqina kwesondo lokugaya kunethonya elikhulu ekuvimbeni. Ukuqina okuphezulu kwesondo lokugaya kune-conductivity ephezulu ye-thermal, engafaneleki ukuchithwa kokushisa okungaphezulu, kodwa kunenzuzo ukuthuthukisa ukunemba kokucubungula nokuqina.

I-6) Ukukhethwa kokugxila kwesondo lokugaya kuyisici esibalulekile, esinomthelela omkhulu ekusebenzeni kahle kokugaya kanye nezindleko zokucubungula. Uma ukugxila kuphansi kakhulu, ukusebenza kahle kuzothinteka. Uma kungenjalo, izinhlamvu ezilimazayo zizowa kalula, kodwa uhla lokugxilisa ibhondi olungcono kakhulu nalo luhle.