I-Cold saw blade: Iyini kanye nezinzuzo

I-Cold saw blade: Iyini kanye nezinzuzo

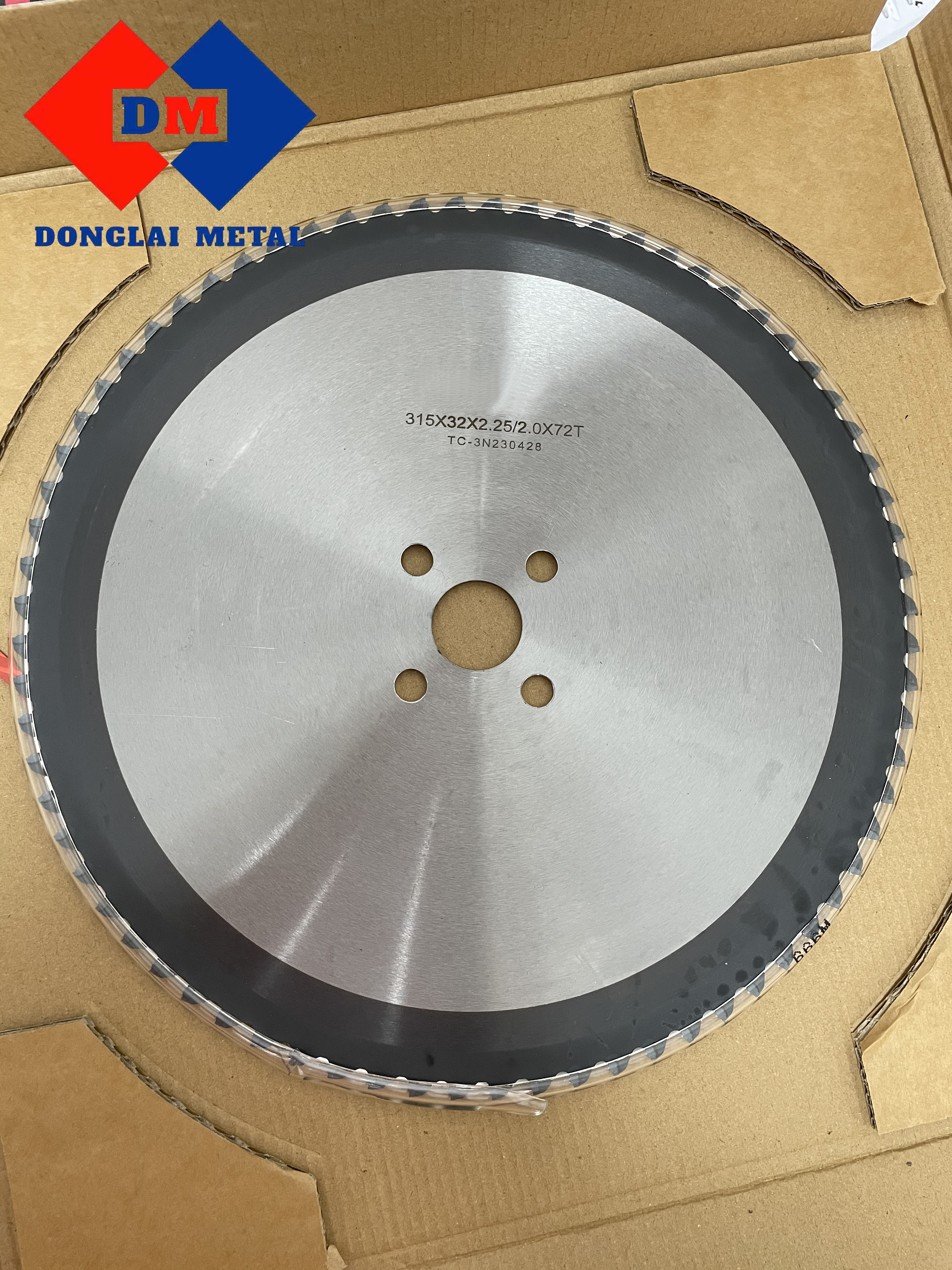

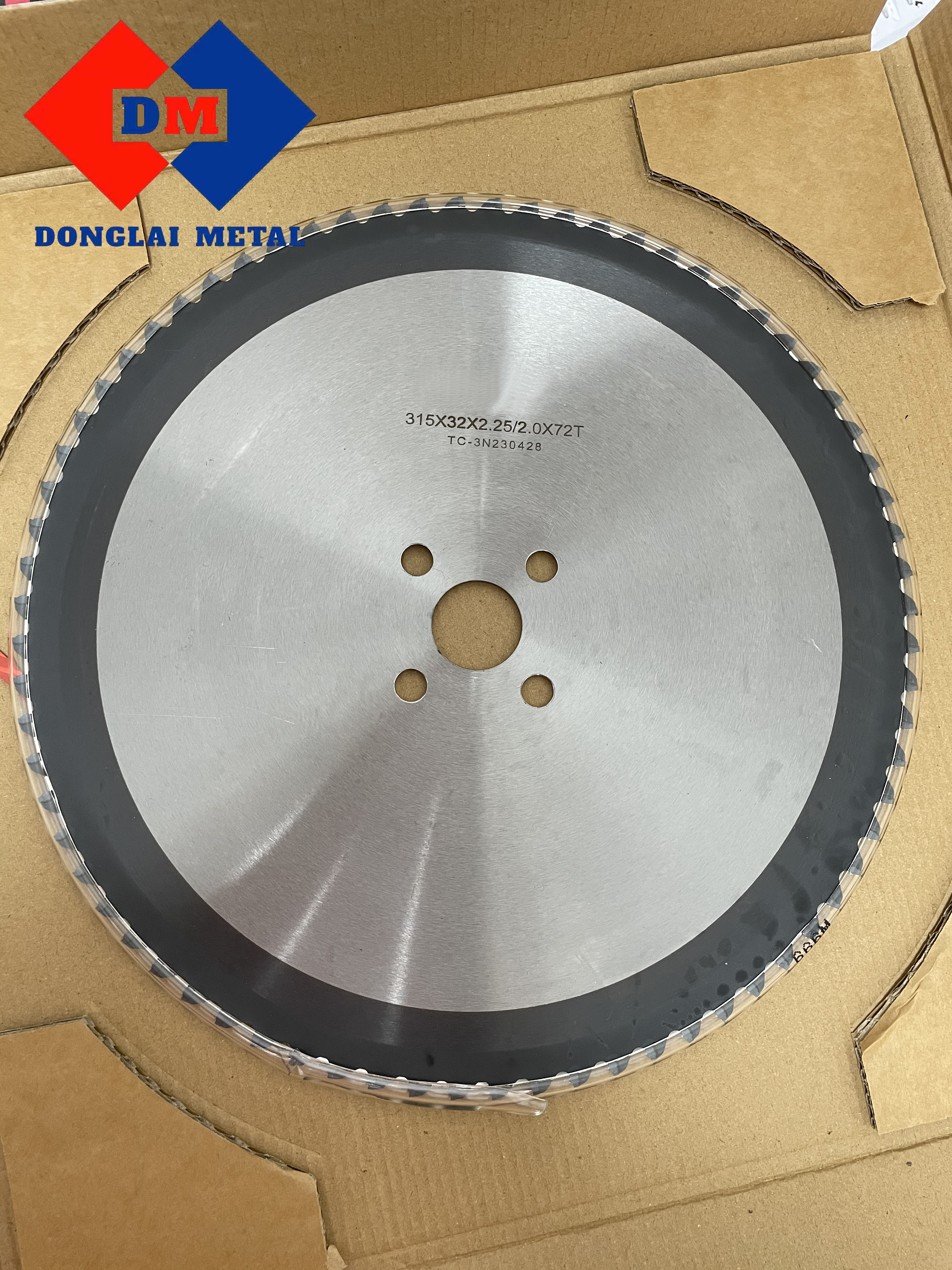

Isaha elibandayo, elaziwa nangokuthi isaha elibandayo lensimbi, igama elisetshenziselwa ukuchaza inqubo yokusika umshini oyisiyingi wensimbi. Phakathi nenqubo yokusika insimbi, ukushisa okukhiqizwa ngamazinyo e-saw blade ukusika ucezu lokusebenza kudluliselwa ku-sawdust, ukugcina ucezu lokusebenza kanye ne-saw blade ipholile. Yingakho kubizwa ngokusaha okubandayo.

Ukuqhathanisa

(Uma kuqhathaniswa ne-Manganese Steel Flying Saw)

I-Cold saw cutting kanye ne-friction sawing ihlukile, ikakhulukazi endleleni yokusika:

Insimbi ye-Manganese flying saw blade: I-manganese steel saw blade izungeza ngesivinini esikhulu ukuze ikhiqize ukungqubuzana nomsebenzi. Ukungqubuzana phakathi kwe-saw blade kanye ne-workpiece phakathi nenqubo yokusika kudala amazinga okushisa aphezulu abangela ukuphuka kwepayipi elihlanganisiwe. Lokhu empeleni inqubo yokushiswa, okuholela ekubonakaleni kokushiswa okuphezulu phezulu.

I-high-speed steel cold cut saw: incike ekujikelezeni kancane kwesaha yensimbi enesivinini esikhulu kumapayipi ashiselwe esikwa yi-mill, angafinyelela imiphumela yokusika ebushelelezi nengenaburr ngaphandle komsindo.

Izinzuzo:

Ijubane lokusika liyashesha, lifinyelela ukusebenza kahle kokusika kanye nokusebenza kahle okuphezulu.

Ukuphambuka kwe-blade kuphansi, futhi awekho ama-burrs endaweni enqunyiwe yepayipi yensimbi, ngaleyo ndlela kuthuthukisa ukunemba kokusika kwe-workpiece, nokwandisa impilo yesevisi ye-blade.

Ukusebenzisa indlela ebandayo yokugaya nokusika, ukushisa okuncane kakhulu kukhiqizwa ngesikhathi sokusika, okugwema izinguquko ekucindezelekeni kwangaphakathi.kanye nesakhiwo sempahla yesigaba sokusika. Ngesikhathi esifanayo, i-blade icindezela kancane ipayipi yensimbi futhi ayibangeli ukuguqulwa kodonga lwepayipi nomlomo.

Izinto zokusebenza ezicutshungulwe ngesaha elibandayo lensimbi elinesivinini esikhulu zinekhwalithi yobuso bokuphela okuhle:

·Ngokwamukela indlela yokusika eyenziwe kahle, ukunemba kwesigaba sokusika kuphezulu, futhi awekho ama-burrs ngaphakathi nangaphandle.

·Indawo esikiwe iyisicaba futhi ibushelelezi ngaphandle kokudinga ukucutshungulwa okulandelayo okufana ne-chamfering (ukunciphisa ukushuba kokucubungula kwezinqubo ezilandelayo), ukonga kokubili izinyathelo zokucubungula nezinto zokusetshenziswa.

·I-workpiece ngeke ishintshe impahla yayo ngenxa yokushisa okuphezulu okukhiqizwa ukungqubuzana.

·Ukukhathala komsebenzisi kuphansi, ngaleyo ndlela kuthuthukise ukusebenza kahle kokusika.

·Azikho izinhlansi, uthuli noma umsindo ngesikhathi sokusika, okwenza kube nobungane bemvelo nokonga amandla.

Impilo yesevisi yinde, futhi i-blade ingacijwa ngokuphindaphindiwe kusetshenziswa umshini wokugaya i-saw blade. Impilo yesevisi ye-blade ecijile ifana neye-blade entsha. Lokhu kuthuthukisa ukusebenza kahle kokukhiqiza futhi kunciphisa izindleko.

Ubuchwepheshe Besicelo:

Khetha amapharamitha wokusaha ngokususelwa kumpahla kanye nokucaciswa komsebenzi osikwayo:

·Nquma iphimbo lamazinyo, ukuma kwezinyo, imingcele ye-engeli yangaphambili nangemuva yamazinyo esaha, ubukhulu bensingo, kanye nobubanzi bensingo.

·Nquma ijubane lokusaha.

·Nquma izinga lokuphakelwa kwamazinyo.

Ukuhlanganiswa kwalezi zici kuzoholela ekusebenzeni kahle kokusaha kanye nempilo ephezulu yesevisi ye-blade.

I-Cold saw blade: Iyini kanye nezinzuzo

I-Cold saw blade: Iyini kanye nezinzuzo