Isingeniso Solwazi Lwe-Diamond Saw Blade

Idayimane lesaha ledayimane liyinto enzima kakhulu emhlabeni, lisebenzisa idayimane ukusika zonke izinto eziqinile ezingaphansi kokuqina kwalo, njengetshe, njengokhonkolo oqinisiwe, njengezitini, njengamathayili nezinye izinto zokuhlobisa. . Ngakho yiluphi ulwazi ama-diamond saw blades analo? Ake sithole ngezihloko ezilandelayo:

1: I-diamond saw blade engcono kakhulu idinga ukuzinza, ibukhali futhi kungabi lula ukuqhekeka. Ukuzinza kusho ukuthi ukukhanya kwe-saw blade kuphakeme ngokwanele, i-substrate ayikhubazekile, futhi i-angle ye-blade welding inhle. Ubukhali busho ukuthi idayimane esesigabeni iphukile kahle, futhi ikhono lokusika linamandla. Ukuthi akulula ukuqhekeka kusho ukuthi into eyisikiwe akulula ukuyiqhekeza. Isizathu esiyinhloko ukuthi ngenxa yokuthi ubukhali be-saw blade buphakeme kakhulu, i-saw blade ngeke ishaye itshe, futhi ngokwemvelo kuyoba nokuqhekeka okuncane.

2: Ukunemba kokusika umehluko omkhulu phakathi kwama-saha ama-high quality kanye nama-saha blades ajwayelekile. Enqubweni yokujikeleza okuqhubekayo kwe-saw blade, kuzoba nokuchezuka okuncane, futhi lapho i-saw blade iqala ukusika itshe, kulula ukuphambuka okukhulu ekunembeni kokusika, ikakhulukazi inhlanganisela ye-multi-blade yebhuloho. umshini, ikhwalithi ye-saw blade inquma ukunemba kwetshe lokusika, okungukuthi, ukuqina kwe-slab yamatshe. Ngomshini wokusika ibhuloho le-infrared, ukubonakaliswa okusobala kakhulu kokunemba kokusika kwama-saw blades asezingeni eliphezulu ukunemba kobude nobubanzi betshe, futhi umehluko phakathi kwama-saw blades amahle angaphansi kuka-0.2mm.

3: Ukusikwa kwejubane lokuphakelayo okuqinile kuyisinqumo sokuthi ubukhali be-saw blade kugcinwa noma cha. Ijubane lokuphakelayo lokusika yijubane lokusika le-saw blade inqubo eya phambili lapho usika itshe. Ukusika okuzinzile kuqala kusho ukuthi ijubane lokusika lizinzile futhi ngeke livele isimo sokusheshisa okwesikhashana bese kancane kancane, ijubane lokudla elibushelelezi libonisa ukuthi i-saw blade igcina ikhono elihle lokusika, ijubane lingagcinwa, kanye ne-saw blade. ngeke ibe buthuntu noma isheshe ngenxa yejubane, okubonisa ukuthi i-saha blade isesimweni esihle sokusika.

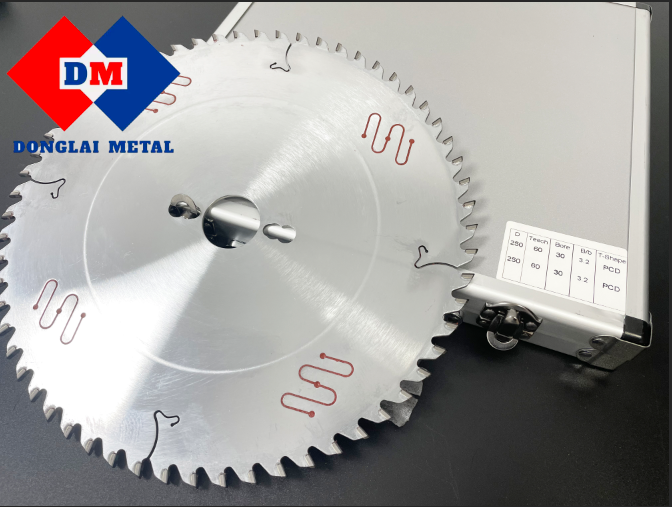

4: Izinhlobo ezahlukene ze-groove zama-saha blades zimelela amakhono ahlukene okusika. Uhlobo lwe-groove oluyinhloko lunomumo obalulekile wembobo. Amazinyo e-saha alolu hlobo lwe-groove ahlukene. Lapho ukusika, izinyo ngalinye linekhono lokuzisika elizimele, elikhuthaza amandla amazinyo ngamanye, ngakho linobukhali obukhulu nokusebenza kahle kokusika. ngcono. Bese kuba nomsele obanzi omise okwe-U. I-groove ebanzi efana ne-U kanye ne-keyhole groove iyafana ngenhloso, kodwa i-U-shaped ayikuhlukanisi ngokuphelele ukuxhumana phakathi kwamazinyo amabili esaha, ngakho-ke ubukhali buyoba kubi kakhulu, kodwa ukusebenza kokusika ukuqhubeka kunentuthuko enkulu. Bese kuba nomsele omncane omise okwe-U. I-saha blade yalolu hlobo lwe-groove inokusebenza okuqinile okuqhubekayo futhi ngokuvamile isetshenziselwa ukusika imabula enobunzima obuqinile. Ekugcineni, kunemifantu yesaha enezimbotshana eziphambanayo kanye nemigodi yokudonsa. Lolu hlobo lwe-saw blade lunekhono eliqinile lokusika eliqhubekayo, kodwa alwanele mayelana nokusebenza kahle kokusika.

I-5: I-serration ehlukene ye-saw blade imelela umehluko ekusebenzeni kokusika. Kunezinhlobo eziningi zamasaha blades. Ngokuvamile, izingxenye ze-saw blade ezivamile zinohlobo lwe-M. Iningi lalawa ma-saw blades asheshisa ukusika. Imele ubukhali nokusebenza kahle kwe-saw blade. Ezinye izimo zamazinyo, okuhlanganisa okumise okwe-V, okumise okwe-W, uhlobo oluqinisiwe olumise okuka-T, uhlobo lukathayela, njll., zonke ezokwandisa ikhono lokusika elikhethekile lensingo yesaha.

I-6: Kunezici ezimbili zesisekelo se-saw blade okufanele sinakwe: ukumelana nokushisa okuphansi kanye nokumelana nokushisa okuphezulu, owaziwa nangokuthi i-coefficient yokwandisa.

Ngokuvamile, ama-diamond saw blades asenolwazi oluningi okufanele akwazi. Kuphela ngokwazi okwengeziwe, singakwazi ukuqonda indlela engcono kakhulu yokusika enqubweni yokusika, sinwebe isikhathi sokusika i-blade yesaha, futhi sandise ukusebenza kahle kwe-saha blade.