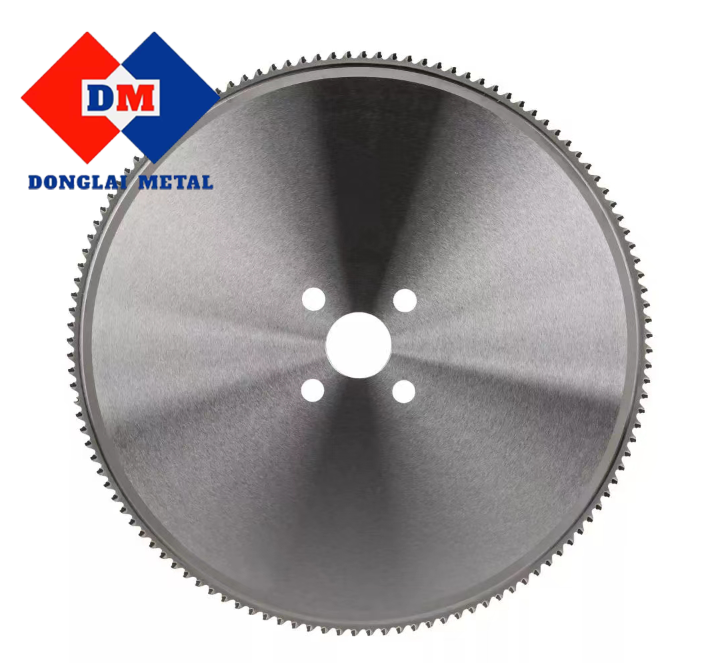

Advantages of high-speed steel cold-cut saw blades:

The sawing speed is fast, the cutting efficiency is optimized, and the work efficiency is high; the saw blade deflection is low, the section of the steel pipe to be sawed has no burrs, the sawing accuracy of the workpiece is improved, and the service life of the saw blade is maximized.

1. The sawing method of cold milling is adopted. The sawing process generates little heat, which avoids the change of internal stress and material structure at the cut section. At the same time, the saw blade has a small pressure on the steel pipe, which will not cause the pipe wall orifice out of shape.

2. The quality of the cut end surface of the workpiece processed by the high-speed steel cold-cut saw is good: the optimized cutting method is adopted, the section after cutting is of high precision, there are no burrs inside and outside, the cutting surface is smooth and clean, and no follow-up processing such as flat haed chamfering is required (reduce The processing intensity of the next process), saves the process and raw materials; the workpiece will not change the material due to the high temperature generated by friction; the operator's fatigue is low, and the sawing efficiency is improved; there is no spark, no dust, no noise during the sawing process; environmental protection and energy saving.

3. Long service life, you can use the saw blade grinding machine to repeatedly grind the teeth, the service life of the saw blade after grinding is the same as that of the new saw blade. Improve production efficiency and reduce costs.