Cold Cut Saw vs Hot Cut Saw

Cold cutting saw: Metal is quickly cut off by a circular saw blade rotating at high speed at room temperature, and the cutting end surface is smooth and clean like a mirror.

Hot cutting saw: commonly known as hacking saw, computer flying saw, also called friction saw. High-speed cutting is accompanied by high temperature and sparks, the cutting end surface is purple, and there are many flashes and burrs.

Sawing method:

Cold cutting saw: The high-speed steel saw blade rotates slowly to mill off the welded pipe, so it can be burr-free and noise-free. The sawing process produces very little heat, and the saw blade exerts little pressure on the steel pipe, which will not cause deformation of the pipe wall orifice.

Hot cutting saw: The ordinary computer flying saw is a tungsten steel saw blade that rotates at high speed, and the heat generated by the contact with the welded pipe causes it to break, which is actually burnt. High burn marks are visible on the surface. A lot of heat is generated, and the saw blade exerts a lot of pressure on the steel pipe, causing the deformation of the pipe wall and nozzle to cause quality defects.

Length accuracy:

Cold cutting saw: fixed length ± 2.0mm, repetition accuracy of the same specification ± 0.5mm, no need for secondary sizing, saving process and raw materials

Hot cutting saw: ±2.5mm, most of them need to be cut to length offline twice, which wastes human energy and raw materials

Cut quality:

Cold-cut saw: small internal and external burrs, smooth and smooth milling surface, no need for follow-up processing, saving processes and raw materials

Hot-cut saw: The internal and external burrs are very large, and subsequent processing such as flat head chamfering is required, which increases the cost of manpower energy and raw material consumption

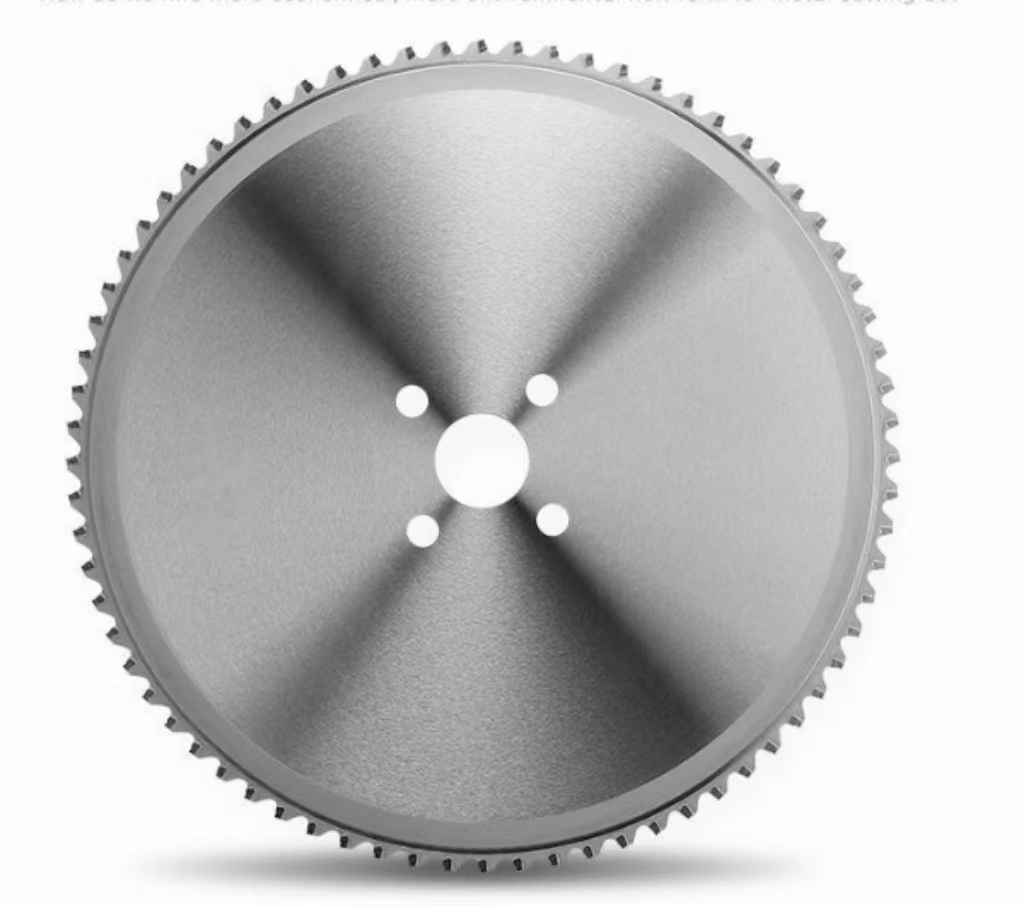

Is the difference between a cold cut saw and a hot cut saw the saw blade?

Obviously, choosing a good quality saw blade is one of the factors to obtain a good sawing effect. At the same time, there are many deeper and most important factors that affect the sawing effect. For example, the abnormal vibration generated when the saw machine is running, the gear gap is too large, the motor power is too small, the use of fixtures and the ratio of coolant are not appropriate, the saw Too high machine speed, too slow feed speed etc will cause damage to the saw blade and affect the sawing effect. Therefore, the quality of the flying saw machine and the application parameters of sawing directly affect the sawing quality of the workpiece, the sawing efficiency and the service life of the saw blade. Professional supporting sawing equipment + professional sawing parameters + high-quality saw blade + professional saw blade parameters = high-quality sawing effect