The use and maintenance skills of woodworking multi-blade saw

The use and maintenance skills of woodworking multi-blade saw

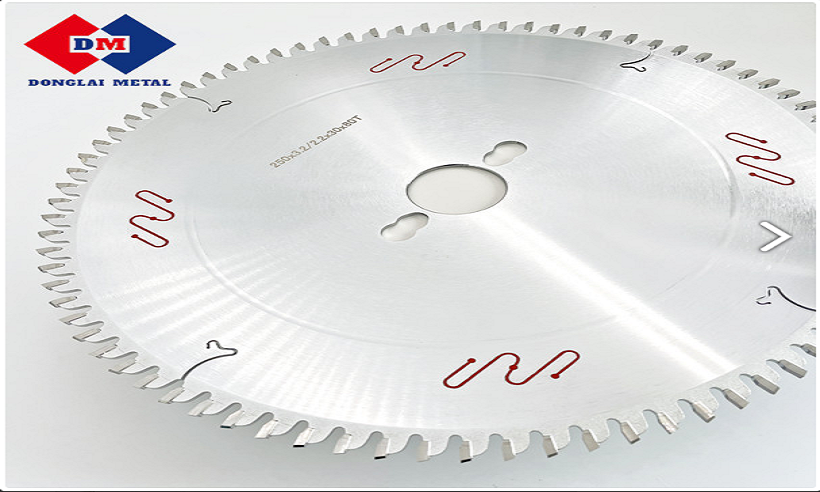

* How to use: The multi-blade saw blade is a saw blade that is installed and used together in groups. It is generally used for longitudinal cutting of solid wood, for making squares and strips. The general tooth type is BC or P, and the saw path is within the range of 1.6-3.2mm, which can greatly improve the work efficiency of workers and improve production efficiency.

*Auxiliary function

1.Outer scraper - generally used for cutting wet wood, which is beneficial to chip removal, greatly reducing the sticking of wood chips to the material

2.Inner scraper - generally used for hardwood cutting, which is conducive to trimming the burrs on the cutting surface, Keep the smooth finish

3. keyway - let the saw blade be better fixed on the spindle and run smoothly, prevent the saw blade from slipping, and clamp the saw blade.

*Reasons for burning saw blades

1.Saw blades are not sharp

2.Too many saw blade teeth or too many saw blade installations

3.Saw blade heat dissipation is not good

4.The material does not match the processing range of the machine

5.The machine speed does not match the feed speed;

*Solution

1. If the saw blade is not sharp, need to grind the saw blade in time

2. Choose a saw blade with fewer teeth or reduce the number of installed pieces

3. It is best to buy a saw blade with cooling holes, or you can add water (other coolant) to reduce the temperature.

4. Properly adjust the machine or select the specification and size of the processing material

5. Properly adjust the feeding speed according to the material material