To cut aluminum alloy, special alloy saw blade should be selected. Generally, the material type,variety, thickness and number of teeth of the saw blade are all required.

Special saw blades like those for cutting acrylic, solid wood, plexiglass, etc. are absolutely unusable, because the effect is definitely not good, and it will be damaged quickly, which is unnecessary. Because the special saw blade is originally manufactured according to the cutting characteristics of aluminum alloy metal materials.

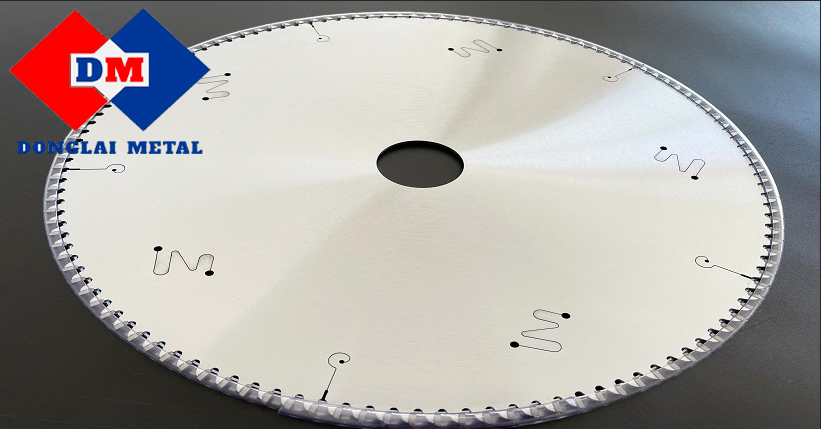

Among them, there are other requirements when choosing, such as the number of teeth, model and so on. After choosing an alloy saw blade, be sure to choose a saw blade with stepped flat teeth, not a ceramic cold saw, high-speed steel saw blade or something. If you choose the wrong one at the beginning, you will not have good results later.

At the same time, the type of saw blade selected is also very important, mainly including a series of parameters such as the outer diameter of the saw blade, aperture, thickness, number of teeth, etc. These data have a great influence on the cutting effect. If any link is selected wrong, the cutting effect of a certain part will be unsatisfactory.

For example, if the outer diameter of the selected saw blade is too large, the equipment may not be able to be installed; if the outer diameter is too small, the cutting ability will be weakened, and it may not be cut at one time. As for the thickness of the saw blade, it is related to the service life. If it is thicker, the loss rate will be reduced, and the life of the saw blade will be extended accordingly. However, if it is not needed for a long time, it is not necessary to choose a particularly thick one.