When cutting aluminum saw blades with burrs, there are mainly three reasons. First of all, it is necessary to confirm whether the saw blade itself has quality problems. The second is that the saw blade has been used for a long time, it becomes blunt, and the edge of the blade is not fast. At this time, it needs to be sharpened.

Causes of burrs when sawing:

First, Reasons for saw blades:

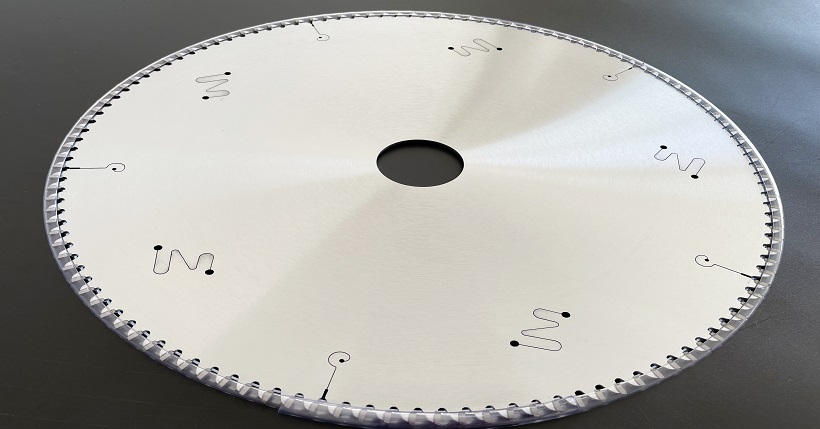

1. Too few teeth on the saw blade.

2. The quality of the saw blade. The quality problems of the saw blade often require the saw blade to be returned to the factory for inspection in order to obtain the quality parameters of the saw blade, such as: wrong tooth shape, substandard waist strength, wrong height difference of sawtooth, poor concentricity, etc., and this also has something to do with what kind of saw blade suppliers customers look for when purchasing saw blades, and finding a dedicated saw blade manufacturer. Most of these problems will be avoided when selecting saw blades.

Second, the reasons for the equipment:

1. The precision of the spindle is not up to standard.

2. The flatness of the flange is not good or there are foreign objects. This is also what happens in many companies, so we must pay attention to it.

3. The straightness of the saw blade is not good. This also requires the equipment supplier to maintain the equipment frequently to prevent such problems.

4. The saw blade is installed backwards. Although this problem is rare, there are still cases of occurrence.

5. The material is not compacted. This situation often occurs when the shape of the material is not very regular.

6. Belt slipping causes the speed of the saw blade to be too low.

7. The tool feed is too fast. In this case, it is best to find a responsible and reliable equipment manufacturer. Precaution will be explained in advance when the equipment is handed over.

Finally, Material reasons:

The material is too soft, the surface is oxidized, the material is too thin, and the material is deformed, resulting in sweeping after sawing, and the material grade (high silicon aluminum).