Donglai Metal provide high performance saw blades, offer cost-saving solutions in your different cutting industry!

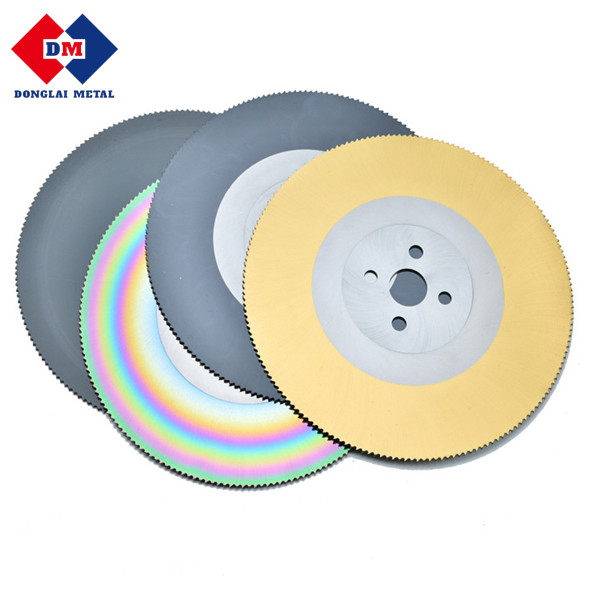

HSS Circular Saw Blades With PVD Coating

DM can supply HSS circular saw blades with all PVD coatings in either M2 or M35 quality as blanks or toothed. Depending on the grade of material it is advised to change angles on the teeth to suit your application for pipes, sections and solid ferrous materials.

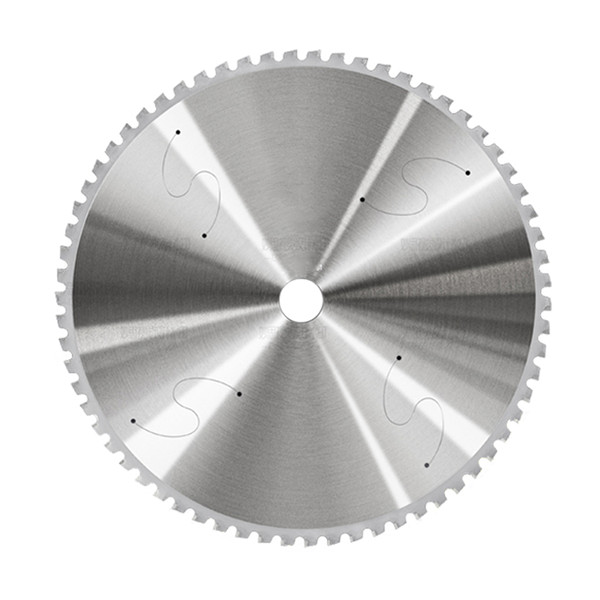

HSS M2-DMo5

Quality circular hss saw blades in high speed steel (5% molybdenum) suitable for cutting steel alloys with a tensile strength between 500 N/mm² and 800 N/mm². These saw blades can be used on all saws to cut tubes, structural and solid sections up to 200 mm diameter or thickness.

HSS M35-Co5%

This is a super high speed steel that, in addition to the alloy elements already present in the Dmo5, also contains 5% cobalt. Circular saws in super high speed steel (5% cobalt content) suitable for cutting steels and alloys with tensile strengths over 800 N/mm². These blades are suitable for use on most saws to cut tubes, structural and solid sections up to 200 mm diameter.

PVD Coatings – TiN, TiCN, TiALN. These coatings are applied to increase surface hardness, reduce friction and allow faster machining rates. These benefits vastly increase blade life giving a lower cost per cut.

TiN Coating TiCN Coating AlTiN Coating Steam Oxide

Steam Oxide

These blades have a standard hardness of 64 - 65 Rockwell and are used for general purpose cutting of all materials including non-ferrous. Diameters from 200 - 500mm.

(Titanium Nitirde) TiN

Gold in colour. This PVD coating increases the surface hardness to 2300 - 2500 (HV 0.05) Can be used on all materials including stainless steel. A popular coating applied to tooling for increasing surface hardness, lowering friction and retaining the cutting edge.

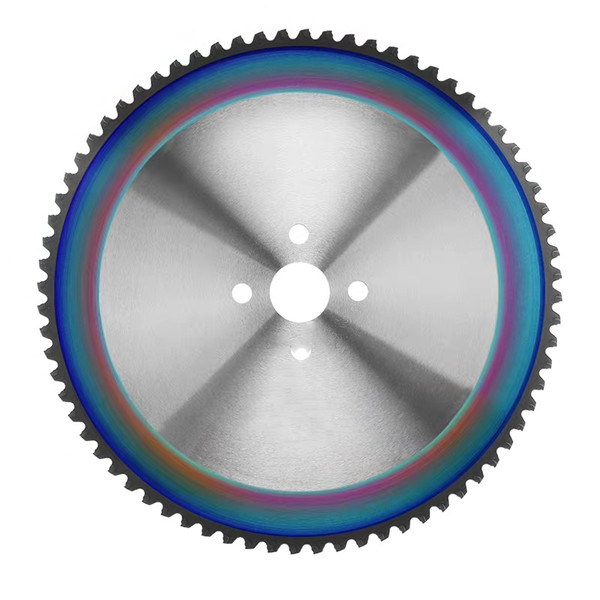

(Titanium Carbonitride) TiCN

Blue/purple colour. The main advantage of this PVD coating is the increase in surface hardness 3000 (HV 0.05). Much like the characteristics of TiN, this coating has higher resistance to abrasion and heat, allowing higher cutting rates.

(Titanium Aluminium Nitride) TiAlN

Purple / grey in colour. This PVD coating is an extra tough treatment that allows higher machining rates with a minimum of cutting lubricant, specific for stainless steels and other arduous applications. Its reduced thermal conductivity makes it the best coating used at high temperatures or dry cutting.

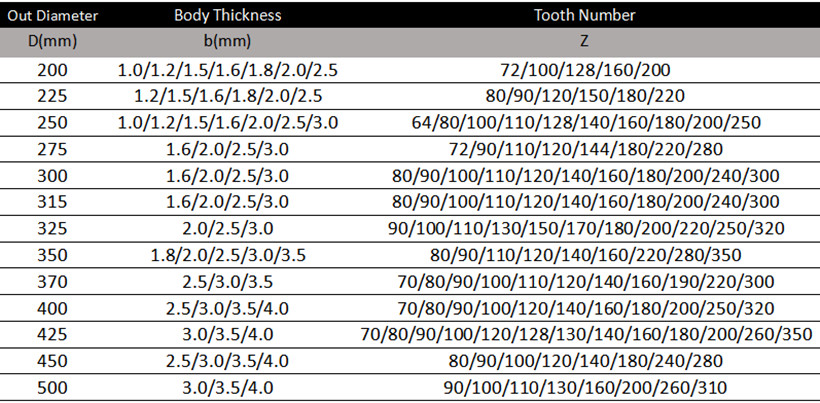

Product Parameters:

Note: Can be customized according to customer's requirements.

FACTORY TOUR

Hunan Donglai Metal Technology Co., Ltd.

ADDRESS:Building 1 Taishan Road, Tianyuan District Zhuzhou Hunan China

Phone:+86 187 0733 6882,+86 152 7339 2257

Email:info@donglaimetal.com