In the field of modern industrial production, aluminum cutting saw blades play a vital and indispensable role.Its importance is not only reflected in improving production efficiency and ensuring product quality, but also deeply affects the stability and economic benefits of the entire production process.

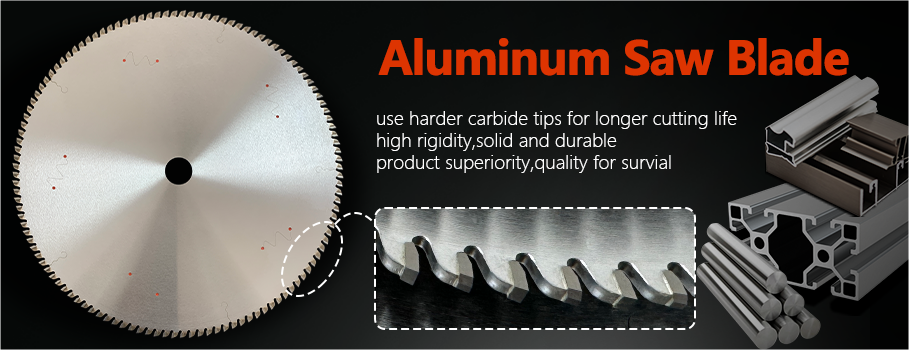

First of all, the aluminum cutting saw blade directly determines the accuracy and quality of aluminum material cutting.Among many industrial products, the requirements for dimensional accuracy and surface flatness of aluminum parts are extremely strict.A high-quality aluminum cutting saw blade, with its precise tooth design and excellent rigidity, can ensure neat and smooth cuts on aluminum materials during the cutting process, reducing burrs and deformation.This is crucial for products that require high-precision assembly, such as aerospace components and aluminum structural parts in automotive manufacturing.Precise cutting can not only improve product performance and reliability, but also reduce subsequent processing steps and reduce production costs.

Secondly, aluminum cutting saw blades significantly affect production efficiency.High-efficiency aluminum cutting saw blades can complete cutting tasks at a faster speed and maintain stable performance during long-term continuous operation.Its excellent wear resistance and sharp teeth make the cutting process smoother and reduce production interruptions caused by frequent replacement of saw blades due to wear.By choosing the right aluminum cutting saw blade, you can optimize the cutting parameters and increase the output per unit time, thus meeting the market demand for rapid supply of products.

In addition,aluminum cutting saw blades play a key role in reducing production costs. Although the initial purchase cost of a high-quality saw blade may be relatively high, its excellent performance and long service life can achieve cost sharing and savings in long-term production operations.In contrast, low-quality saw blades may need to be replaced more frequently, which not only increases the purchase cost of the saw blades, but also leads to reduced production efficiency and increased scrap rate. Additionally, efficient aluminum cutting saw blades can reduce energy consumption, further reducing overall costs in the production process.

In summary, the importance of cutting aluminum saw blades in industrial production cannot be underestimated.It is not only a key tool to achieve high-quality and high-efficiency production, but also an important factor in ensuring production safety, reducing costs and promoting technological progress in the industry.Enterprises should attach great importance to the selection, use and maintenance of aluminum saw blades during the production process, so as to give full play to its huge value in industrial production and enhance its market competitiveness and sustainable development capabilities.