- Super User

- 2025-04-11

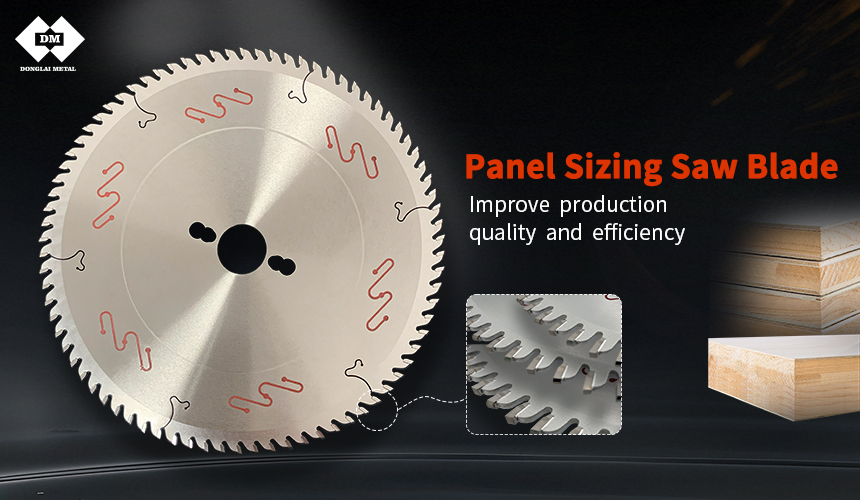

How to choose the appropriate panelsizing saw blade according to the material of

Choosing the right panesizingl saw blade is crucial to ensuring cutting quality, improving work efficiency and extending the service life of the saw blade.

Here is how to choose a saw blade based on the material and thickness of the board being cut:

Choose according to the material of the board

For soft solid wood, such as pine and fir, you can choose a saw blade with relatively fewer teeth and larger tooth pitch.Because soft wood is easy to cut, the larger tooth pitch allows sawdust to be discharged more smoothly, reducing saw blade clogging and improving cutting efficiency. Generally speaking, a saw blade with 8 - 10 teeth per inch is suitable.

For hard solid wood, such as oak, walnut, etc., you should choose a saw blade with more teeth and smaller tooth angle.A larger number of teeth can increase the tooth contact during cutting, making the cutting smoother and reducing tearing and chipping on the wood surface.It is recommended to choose a saw blade with 10 - 14 teeth per inch and a tooth angle between 15° - 20°.

Artificial board particleboard and medium-density fiberboard (MDF) have a uniform texture, but produce a lot of dust, so you need to choose a saw blade with good chip removal performance.Usually a saw blade of 10-12 teeth per inch is more suitable, and the front angle of the saw can be appropriately large, around 20° -25 °, which can better cut the plate and reduce dust generation.

Plywood is made of multiple layers of thin wood slices glued together and it is easy to delaminate when cut. To avoid this situation, you should choose a saw blade with more teeth and sharper teeth, preferably 12 - 14 teeth per inch, and the edge of the saw teeth should be kept sharp to reduce tearing between the layers of plywood.

When cutting plastic plates, the saw blade is prone to sticky chips, which affects the cutting quality.Therefore, it is necessary to choose a saw blade with special tooth shape and smooth surface.For example, a saw blade with alternating bevel teeth (ATB) can effectively prevent plastic sticking, and the specification of 8-10 teeth per inch is suitable for cutting most plastic sheets.In addition, the material of the saw blade is best with good wear resistance to extend the service life of the saw blade.

Aluminum alloy and other metal plate cutting aluminum alloy and other metal plate need to use a special metal cutting saw blade, this saw blade is usually made of cemented carbide material, with higher hardness and wear resistance.The number of teeth of the saw blade is generally more, 14-18 teeth per inch, to ensure the accuracy and surface quality when cutting.At the same time, in order to effectively heat dissipation and chip removal, the design of the heat dissipation hole and chip removal slot on the saw blade is also very important.