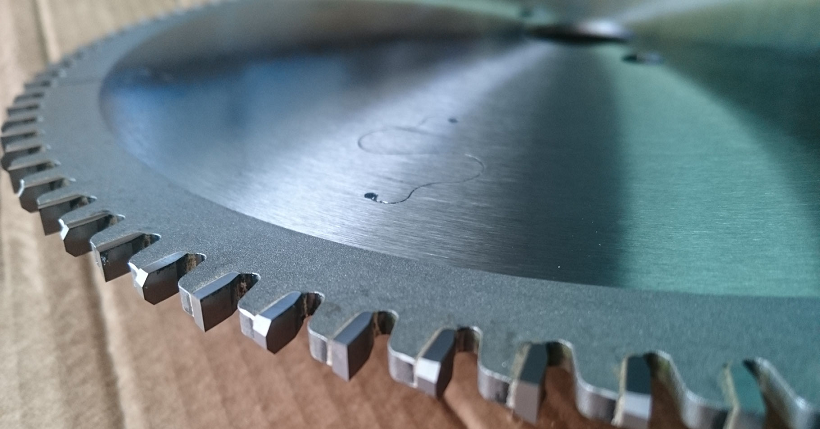

Izinhlobo zezinyo ezivame ukusetshenziswa ze-alloy saw blades zingamazinyo angakwesokunxele nangakwesokudla (amazinyo ahlukile), amazinyo ayisicaba, amazinyo ayisicaba (amazinyo aphezulu naphansi), amazinyo e-trapezoidal (amazinyo ahlangene), amazinyo e-dovetail (amazinyo angama-hump) ezingavamile zezimboni Izinga lesithathu kwesokunxele kanye eyodwa kwesokudla, kwesokunxele-kwesokudla kwesokunxele-kwesokudla amazinyo flat nokunye.

1. Amazinyo angakwesokunxele nangakwesokudla asetshenziswa kabanzi, isivinini sokusika siyashesha, futhi ukugaya kulula. Ilungele ukusika nokusaha amaphrofayili ahlukahlukene ezinkuni eziqinile neziqinile kanye namabhodi okuminyana, amabhodi anezingqimba eziningi, amabhodi ezinhlayiyana, njll. Amazinyo angakwesokunxele nangakwesokudla ahlomeke amazinyo okuvikela ukuzungeza amazinyo ejuba, afaneleka ukusika i-longitudinal yamabhodi ahlukahlukene anamafindo esihlahla; ama-saw blade amazinyo angakwesokunxele nangakwesokudla anama-engeli e-rake avame ukusetshenziselwa amaphaneli okusaha. ngenxa yamazinyo abo acijile ahlabayo kanye nekhwalithi enhle yokusika.

2. Unqenqema lwesaha yezinyo eliyisicaba luqinile, ijubane lokusika lihamba kancane, futhi ukugaya kulula kakhulu. Isetshenziselwa ikakhulukazi ukusika izinkuni ezijwayelekile, futhi izindleko ziphansi. Isetshenziselwa kakhulu amasaha e-aluminium anobubanzi obuncane ukuze kuncishiswe ukunamathela ngesikhathi sokusika, noma isetshenziselwa ama-grooving saw blades ukuze kugcinwe iphansi le-groove flat.

3. Izinyo eliyisicaba liyinhlanganisela yezinyo le-trapezoidal nezinyo eliyisicaba. Kunzima kakhulu ukulungisa nokugaya. Kunganciphisa ukuqhekeka kwe-veneer ngesikhathi sokusaha. Ilungele ukusaha amaphaneli asekelwe ngokhuni ahlukahlukene kanye ne-double veneer kanye namaphaneli angashi. Ukuze uvimbele ukunamathela, amasaha ama-aluminium asebenzisa amasaha anamazinyo amaningi anamazinyo ayisicaba.

4. Amazinyo esitebhisi ahlanekezelwe avame ukusetshenziswa engxenyeni engezansi yesaha yesaha. Lapho usaha amaphaneli asekelwe ngokhuni e-double veneer, i-groove saw ilungisa ukujiya ukuze iqedele ukucutshungulwa kwe-groove endaweni engaphansi, bese i-main saw iqedela inqubo yokusaha ebhodini, ukuze Kuvinjwe ukuqhekeka konqenqema lwesaha.

Ukufingqa, amazinyo angakwesokunxele nangakwesokudla kufanele akhethelwe ukusika ukhuni oluqinile, ibhodi lezinhlayiyana, kanye nebhodi eliphakathi nendawo, elingasika izicubu ze-fiber yokhuni ngokucijile futhi lenze i-incision ibe bushelelezi; Ukuze ugcine umsele ugeleza kahle ngezansi, unezinyo eliyisicaba noma amazinyo ayinhlanganisela ayisicaba kwesokunxele nakwesokudla ;Izindawo zokusaha namabhodi angashi ngokuvamile akhetha amazinyo ayisicaba. Ngenxa yezinga eliphezulu lokusika lamasaha e-electronic cutting, ububanzi nogqinsi lwama-alloy saw blades asetshenzisiwe makhulu uma kuqhathaniswa, anobubanzi obungaba ngu-350-450mm nogqinsi obungu-4.0-4.8 Phakathi kwama-mm, iningi lawo lisebenzisa amazinyo ayisicaba nciphisa ukusika onqenqemeni kanye namamaki asaha.