Kungani i-saha blade entsha ingekho kahle njenge-saha blade endala ngemva kokushintshwa komshini? Ngokwempendulo ebanzi yomsebenzisi, kukhona amaphutha, amazwi aphezulu, nezindawo ezisikiwe ezimbi. Yiziphi izizathu zalezi zinkinga? Umhleli olandelayo uzokutshela ukuthi kungani lesi simo senzeka nokuthi singasixazulula kanjani.

Kungani i-saha blade entsha ingekho kahle njenge-saha blade endala ngemva kokushintshwa komshini? Ngokwempendulo ebanzi yomsebenzisi, kukhona amaphutha, amazwi aphezulu, nezindawo ezisikiwe ezimbi. Yiziphi izizathu zalezi zinkinga? Umhleli olandelayo uzokutshela ukuthi kungani lesi simo senzeka nokuthi singasixazulula kanjani.

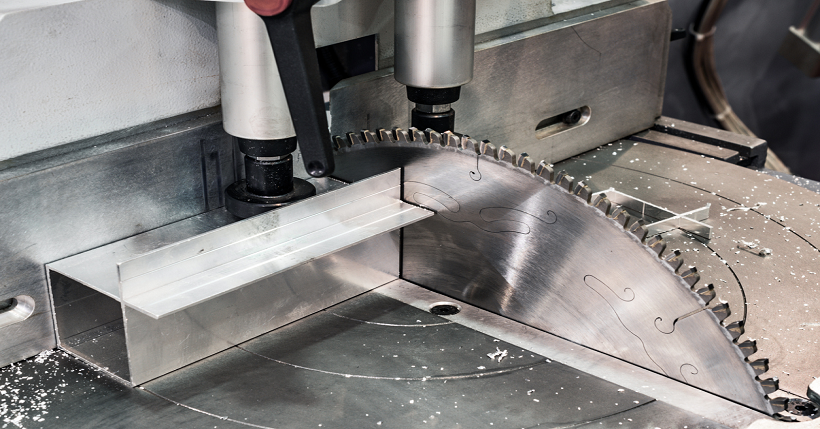

Isizathu 1: I-spindle iyaguga futhi igugile; hlola ukuphuma kwe-spindle ngaphambi kokushintsha i-saw blade. Uma i-ruout idlula ububanzi obunengqondo, i-saw blade izochezuka, okuzoholela kuma-burrs kucezu lomsebenzi olusasiwe. Kuyadingeka ukumisa ukusebenza ngesikhathi bese ubuyisela i-spindle.

Isizathu sesi-2: Kukhona izinto zangaphandle ku-flange; njengoba igama liphakamisa, kukhona izinto zangaphandle ku-flange, okusho ukuthi kukhona ama-aluminium chips namabala epuleti lokucindezela elilungisa i-saw blade, i-saw blade ayifakiwe ngalesi sikhathi i-workpiece yokusaha izophinde ibe ne-burr, into enomsindo. , ngakho-ke umhleli uphakamisa ukuthi kufanele uhlole i-flange ukuze ugweme ukulayisha kwesibili nokuthulula i-saw blade.

Isizathu sesi-3: Ukuthi amafutha okugcoba anele; uchungechunge lomsebenzi wokulungiselela kufanele lwenziwe ngaphambi kokufaka i-saw blade. Uwoyela wokugcoba kuwumsebenzi obalulekile. Ukusebenzisa uwoyela wokugcoba kunganciphisa ukungqubuzana phakathi kwamazinyo esaha kanye nendawo yokusebenza ukuze kungabikho isaha endaweni yokumaka futhi kwandisa impilo yesevisi yensingo yesaha.

Isizathu 4: Faka esikhundleni ngesikhathi ibhodi le-bakelite eligugile futhi elikhubazekile ngenxa yokucubungula isikhathi eside. Uma ibhodi le-bakelite ligugile, lizobangela ukuthi isikhundla sezinto ezibonakalayo sishintshe ngemva kokusikwa kwe-workpiece, futhi i-saw blade izoshanela ummese ngokungathí sina ngesikhathi senqubo yokubuyisela ummese (ithinta impahla ), okuholela ekulimazeni.